Chute magnets ML

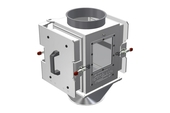

The inline chute magnet (because of its form also sometimes called “lantern” or external pole magnet) is designed for separation of small ferromagnetic particles from materials of worse bulk and pouring properties (such as cereals, flour, powder, sawdust etc.) that could clog the traditional magnetic grate separators.

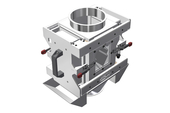

Design of plate separator

We deliver the chute magnet in a stainless steel housing that is to be connected to a pipeline in order to become its integral part. At the separator inlet there is a solid steel dispersion cone that disperses the material flow over the magnetic plates (placed at the inner parts of the separator doors) and ensures a high effectiveness of the separation process.

Which way is plate separator cleaned?

The plate housing magnet is easy to clean and it is not necessary to scrub off the captured ferromagnetic particles. The transparent checking windows on both sides of the separator enable permanent optical inspection of the contamination of the magnetic plates. The standard application of ferrite magnets arranges for nearly unlimited working life, however if you need higher magnetic force we recommend that the magnetic plate separator is fitted with extremely powerful neodymium NdFeB magnets from rare earth ores.

What pipeline is the separtor connected to?

In order to ensure a quick and easy connection, the separator housing is standardly ended by flanges (standard type, Jacob quick-connect fasteners or flanges according to client's needs) in diameters from 100 to 300 mm (but we can adjust the connection type as well as its size to client's requirements).

SOLLAU – our products are welded by real professionals!

SOLLAU certifications:

Authorization to perform welding on pressure equipment according to PED 2014 / 68 / EU

Pressure welder certificate according to EN-ISO 3834 - 2, EN 1090 - 2, EN 13480 - 1 to 5, EN 13445 - 1 to 5

- Magnetic doors move on slides (=maximum cleaning comfort)

- Central diverter directs the material onto the magnetic doors

- Safety lock

- Inspection window

- Removable containers for the separated magnetic particles

- Easy cleaning system

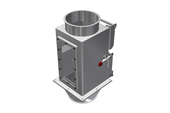

The ML LUX is the premium SOLLAU product in the field of the chute magnets. From similar competitive products, it differs in several exceptional technical solutions.

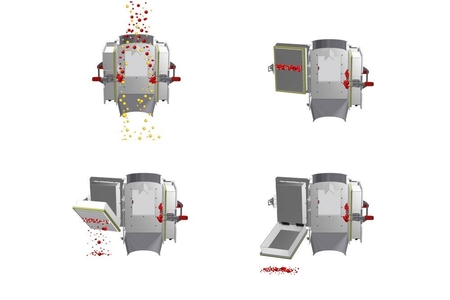

- The magnetic door is placed on slides, making separator’s cleaning very easy (despite the considerable mass - especially at large-diameter separators – the magnetic cores can be easily handled even by women).

- The separator is cleaned in two-steps – first, the sliding door assembly will be moved to the first position, then the magnetic cores will be pushed off to the next position and the ferromagnetic particles accumulated on the surface of the stainless cover plates fall off.

- There are small containers under the magnetic door in which, when cleaning the separator, the separated ferromagnetic material is collected.

- Besides the standard center diverter, this magnetic separator is equipped with a special additional dispersion prism in order to achieve the maximum efficiency of magnetic separation. This gadget is inserted inside the separator and it repeatedly guides the material onto the magnetic plates (in case of poorly penetrable materials or if an extremely high production capacity is needed, the special dispersion profile can be quickly and smoothly removed from the device).

Optionally this model can be also delivered in a fully automatic version.

Ferrite version

| Product | Maximum capacity (m3/h) | Input/output diameter (mm) | Datasheet (EN) |

|---|---|---|---|

| ML LUX 100 F | 10 | 100 | display PDF |

| ML LUX 120 F | 30 | 125 | display PDF |

| ML LUX 150 F | 30 | 150 | display PDF |

| ML LUX 200 F | 75 | 200 | display PDF |

| ML LUX 250 F | 100 | 250 | display PDF |

| ML LUX 300 F | 150 | 300 | display PDF |

Neodymium version

| Product | Maximum capacity (m3/h) | Input/output diameter (mm) | Datasheet (EN) |

|---|---|---|---|

| ML LUX 100 N | 10 | 100 | display PDF |

| ML LUX 120 N | 30 | 120 | display PDF |

| ML LUX 150 N | 30 | 150 | display PDF |

| ML LUX 200 N | 75 | 200 | display PDF |

| ML LUX 250 N | 100 | 250 | display PDF |

| ML LUX 300 N | 150 | 300 | display PDF |

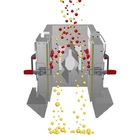

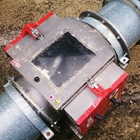

This separator of the proven standard construction has ferrite or neodymium magnetic cores. At the separator inlet there is a center diverter that disperses the material flow over the magnetic plates (placed at the inner parts of the separator doors) and ensures a high effectiveness of the separation process.

When cleaning the separator, the covering stainless steel plates are lifted off from the magnets’ surface and the trapped ferromagnetic contaminants fall off spontaneously. To ensure a permanent visual inspection of the separation process, the device is equipped with large double-sided sight glasses.

Ferrite version

| Product | Maximum capacity (m3/h) | Input/output diameter (mm) | Datasheet (EN) |

|---|---|---|---|

| ML 100 F | 10 | 100 | display PDF |

| ML 120 F | 30 | 120 | display PDF |

| ML 150 F | 30 | 150 | display PDF |

| ML 200 F | 75 | 200 | display PDF |

| ML 250 F | 100 | 250 | display PDF |

| ML 300 F | 150 | 300 | display PDF |

Some products from this model family are available for immediate purchase. We are constantly extending the offer of our magnetic separators in stock so that we can deliver them to you immediately. Please, contact our dealer to inform for their current availability.

Neodymium version

| Product | Maximum capacity (m3/h) | Input/output diameter (mm) | Datasheet (EN) |

|---|---|---|---|

| ML 100 N | 10 | 100 | display PDF |

| ML 120 N | 30 | 125 | display PDF |

| ML 150 N | 30 | 150 | display PDF |

| ML 200 N | 75 | 200 | display PDF |

| ML 250 N | 100 | 250 | display PDF |

| ML 300 N | 150 | 300 | display PDF |

Some products from this model family are available for immediate purchase. We are constantly extending the offer of our magnetic separators in stock so that we can deliver them to you immediately. Please, contact our dealer to inform for their current availability.

- Budget version (attractive price/performance ratio)

- Inspection window

- Magnet is placed in the center-line of the housing (in the middle of the material flow)

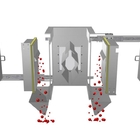

The split-flow magnet ML EKO is an economical, but fully functional alternative to the standard chute magnets. The main difference - compared to the common plate magnets - rests in location of the wedge-shaped magnetic core (covered by a stainless steel jacket) in the middle of the separator (i. e. directly in the material flow).

That is why this separator is not equipped with a dispersion cone in its upper part. However, there are deflectors arranged in several rows on the lateral separator’s sides, repeatedly guiding the material flow to the central magnetic core and ensuring a high efficiency of the separation process. In the course of cleaning, the door with the attached magnetic core is lifted off first, then the stainless covering is moved aside from the magnet and the ferromagnetic particles trapped on the protective cover fall off spontaneously. So, in spite of the cost-effective solution, also this model is equipped both with an easy-cleaning system (so there is no laborious manual removing or scraping the caught Fe impurities) and a good-sized sight glass for the optical control of the material flow and the separation results.

Ferrite version

| Product | Maximum capacity (m3/h) | Input/output diameter (mm) | Datasheet (EN) |

|---|---|---|---|

| ML EKO 100 F | 10 | 100 | display PDF |

| ML EKO 120 F | 30 | 120 | display PDF |

| ML EKO 150 F | 30 | 150 | display PDF |

| ML EKO 200 F | 75 | 200 | display PDF |

| ML EKO 250 F | 100 | 250 | display PDF |

| ML EKO 300 F | 150 | 300 | display PDF |

Neodymium version

| Product | Maximum capacity (m3/h) | Input/output diameter (mm) | Datasheet (EN) |

|---|---|---|---|

| ML EKO 100 N | 10 | 100 | display PDF |

| ML EKO 120 N | 30 | 125 | display PDF |

| ML EKO 150 N | 30 | 150 | display PDF |

| ML EKO 200 N | 75 | 200 | display PDF |

| ML EKO 250 N | 100 | 250 | display PDF |

| ML EKO 300 N | 150 | 300 | display PDF |

- Separation of metal contaminants from feed granules (case study)

- Grinder protection and reduction of maintenance costs in rosin resin processing (case study)

- Efficient removal of ferrous particles in the wood pellet production by using a magnetic separator (case study)

- Separation of iron particles from feathers (case study)

Which industrial branches can the chute magnet be used in?

The external pole magnet separator finds use in food, pharmaceutical, chemical, wood and ceramic industries.