Telescopic rotational magnetic separators MSR-MC

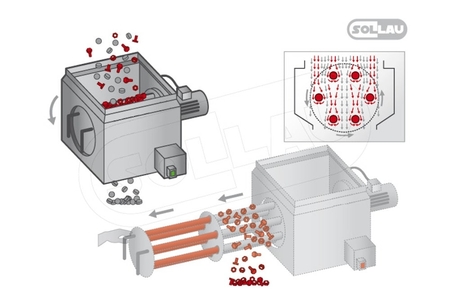

Rotating magnetic separator MSR-MC with the easy cleaning system provides simple, highly efficient and fast separation of the finest ferromagnetic particles (from 30 µm in size) from materials of worse bulk and pouring properties (such as cereals, flour, powder, sawdust etc.) that tend to bridge and could block or damage e. g. the usual magnetic separators equipped with static grids.

Design and advantages of the rotary separator

The rotating magnetic grid consists of a set of magnetic cores hermetically sealed in stainless steel tubes that are inserted into a rotating protective grid. Thanks to the protection of the magnetic cores by two stainless steel tubes, this “tube-in-tube” system offers several advantages:

- long lifetime of the costy magnetic cores (protection from water, mechanical wear during the cleaning etc.)

- elimination of the contamination risk (of the cleaned material by a piece of a chipped magnetic core or its surface coating)

- enhanced abrasive resistance of all the magnetic grid

- a strong magnetic field (generated by the neodymium magnets inside the stainless steel tubes) traps all ferromagnetic particles on the surface of the magnetic grid

- as the set of magnetic tubes is turned by a motor, the rotating grate labyrinth is in a very intense contact with the flowing material and (unlike any standard static magnetic grates) evenly exposed to the abrasive effect of the falling material along the entire circumference of the protective tubes (what contributes to a lower risk of abrading the protective stainless steel tubes as well as to the extension of their lifetime).

- another indisputable advantage of this separator consists in the fact that the cleaned material falls through the permanently rotating system of magnetic tubes (the speed of rotation can be adjusted according to the permeability of the cleaned material), thus preventing clogging of the separator by the flowing material

- the rotating grate magnet can be cleaned very quickly and easily, as all ferromagnetic particles trapped on the grate surface will fall off when the magnetic tubes are pulled out of the stainless steel protective tubes

We are able to manufacture this magnetic separator with the maximum induction of 16 000 G on the core and 11 500 G on the magnetic pipe sheating. Tolerance is +/- 10 %.

What pipeline is the rotary magnetic separator connected to?

In order to ensure a quick and easy application, the separator housing ends with flanges (square, standard, Jacob or customised ones). Depending on the model, the characteristics of the standard version of the MSR-MC Separator are as follows: diameters from 150 to 350 mm, inner heights from 220 to 400 mm and capacities from 6 to 48 m3 per hour (but we can adjust the connection type and separator size to the client's requirements).

Double effective separation

Our product portfolio also includes rotary separators equipped with two magnetic grates placed on the same shaft (i. e., the shaft carries an inner and an outer magnetic ring). Such a configuration allows in fact for a quadruple separation (compared with static one-row grid separators) and that is why this type of separator is usually used in industries in which the cleanliness of the material is a critical factor (e. g., in the pharmaceutical industry).

SOLLAU – our products are welded by real professionals!

SOLLAU certifications:

Authorization to perform welding on pressure equipment according to PED 2014 / 68 / EU

Pressure welder certificate according to EN-ISO 3834 - 2, EN 1090 - 2, EN 13480 - 1 to 5, EN 13445 - 1 to 5

- Magnetic grate moves on slides (it is not necessary to take it out of the separator during cleaning)

- Easier, faster and safer cleaning

- Dense magnetic sieve (up to 12 magnetic tubes)

- 16 000 Gauss on the magnetic core and up to 11 500 Gauss on the stainless steel protective cover

The uniqueness of the technical solution of this model consists in the magnetic grate system moving on telescopic slides, facilitating the separation process.

The cleaning of the separator is a two-step process. Step 1: the complete magnetic grate on the slides is pushed to the first position (i. e., out of the separator). Step 2: magnetic cores are moved to the next position (i. e., out of the protective stainless steel tubes), what results in the automatic falling off of the ferromagnetic particles accumulated on the surface of the protective tubes. there is a small container under the separator door in which, when cleaning the separator, The separated ferromagnetic material is collected.

Thanks to the slides, the magnetic grate forms an integral part of the magnetic separator, making the handling of the grate and the magnetic bars a convenient task.

On a special request, the separator can also be equipped with a shutting flap for a manual interruption of the material flow into the separator as well as with a mechanical or electromagnetic safety lock etc.

| Product | Maximum capacity (m3/h) | Dimension of input/output (mm) | Datasheet |

|---|---|---|---|

| MSR-MC 150 N | 6 | 150 x 150 | display PDF |

| MSR-MC 200 N | 9 | 200 x 200 | display PDF |

| MSR-MC 250 N | 15 | 250 x 250 | display PDF |

| MSR-MC 300/8 N | 24 | 300 x 300 | display PDF |

| MSR-MC 300/12 N Version with one inner and one outer magnetic ring. |

18 | 300 x 300 | display PDF |

- Budget version (attractive price/performance ratio)

- Dense magnetic sieve (up to 14 magnetic tubes)

- 16 000 Gauss on the magnetic core and up to 11 500 Gauss on the stainless steel protective cover

The MSR-MC EKO rotating magnetic separator represents an economical version of the standard MSR-MC separator. Albeit cheaper, the MSR-MC EKO Separator is equipped with the easy cleaning tube-in-tube system, containing neodymium magnets as strong as those used in the standard MSR-MC version.

This magnetic separator was developped in order to offer a rotary separator also to the clients who cannot afford to purchase the standard MSR-MC version for financial reasons or who find the standard variant unnecessary over-sophisticated. As the magnetic grates of the MSR-MC EKO are not placed on slides, the handling of magnetic cores, especially in case of large models, is more difficult. Besides, the separator is not equipped with the the integrated container to trap the ferromagnetic impurities (because the cleaning of the grate takes place outside the magnetic separator).

| Product | Maximum capacity (m3/h) | Dimension of input/output (mm) | Datasheet |

|---|---|---|---|

| MSR-MC EKO 200 N | 9 | 200 x 200 | display PDF |

| MSR-MC EKO 250 N | 15 | 250 x 250 | display PDF |

| MSR-MC EKO 300/8 N | 24 | 300 x 300 | display PDF |

| MSR-MC EKO 300/12 N Versions with two magnetic grids (one internal and one external) |

18 | 300 x 300 | display PDF |

| MSR-MC EKO 350/10 N | 30 | 350 x 350 | display PDF |

| MSR-MC EKO 350/14 Versions with two magnetic grids (one internal and one external) |

26 | 350 x 350 | display PDF |

- Budget version (attractive price/performance ratio)

- High processing capacity (up to 48 m3/h)

- Dense magnetic sieve (up to 24 magnetic tubes)

- 16 000 Gauss on the magnetic core and up to 11 500 Gauss on the stainless steel protective cover

The economical version of the MSR-MC EKO is also offered in a special (extended) variant for large piping systems (using two parallely placed rotors), capable of covering a maximum width of 600 mm.

| Product | Maximum capacity (m3/h) | Dimension of input/output (mm) | Datasheet |

|---|---|---|---|

| MSR-MC EKO 400x200 N | 18 | 400 x 200 | display PDF |

| MSR-MC EKO 500x250 N | 30 | 500 x 250 | display PDF |

| MSR-MC EKO 600x300/16 N | 48 | 600 x 300 | display PDF |

| MSR-MC EKO 600x300/24 N Versions with two magnetic grids (one internal and one external) |

36 | 600 x 300 | display PDF |

Which industrial branches can the rotary magnetic separator be used in?

Rotating grate magnets are mostly used in the area of recycling and waste treatment, food processing, pharmaceutics, wood processing, plastic industries, mining and mineral processing, industrial production of ceramics and glass etc.