Self-cleaning above-the-flow chute plate magnets DND-SFX

The plate magnet DND-SFX with automatic cleaning is a unique solution for the separation of ferrous particles from dry or semi-liquid materials. This automatic separator is used above chutes in order to separate ferrous contaminants by powerful permanent magnets. The captured iron tramp is automatically carried away by a stripper plate into the side waste hoppers.

How does the automated plate magnet work?

The cleaning intervals of the magnetic plate can be individually preset according to the type of product being cleaned and the contamination degree. The flush face plate magnet with automatic cleaning is equipped with very strong neodymium magnets (NdFeB) allowing for the most efficient separation of magnetic particles.

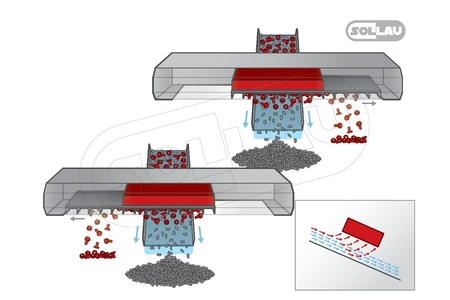

The basic elements of this self-cleaning magnetic separator consist of a self-supporting structure with a stripper plate, strong permanent magnets, a stainless steel chute and waste hoppers (for the removed ferromagnetic impurities). The magnetic plate is suspended above the stainless steel chute (or above a conveyor belt where applicable) and magnetic particles contained in the streaming material are continuously attracted to the stripper plate (equipped on the upper side with powerful permanent magnets). The caught magnetic impurities are then - at preset intervals -transported by the stripper plate into the waste hoppers, and the clean material moves on the chute (or on the conveyor) for further processing.

Which way is the self-cleaning magnet DND-SFX cleaned?

The automatic cleaning is carried out by pneumatic cylinders (moving the stripper pan) and managed by a pre-programmed control unit. The compact DIN 1.4301 stainless steel structure provides for a simple and easy installation into the already existing production lines and at the same time guarantees high resistance and a long working life of the whole system.

Further advantages of the self-clean magnet DND-SFX

Thanks to the entirely unique design, the self-cleaning above-the-flow chute magnetic separator allows for automatic recovery without production stoppage, i. e., no undesirable shutdowns occur. Another indisputable advantage is the fact that the material being cleaned is in direct contact with neither the magnetic cores nor the stripper plate. Therefore, not even high abrasiveness of the processed material can result into the damage of the magnetic separator or into the threat to operational continuity.

SOLLAU – our products are welded by real professionals!

SOLLAU certifications:

Authorization to perform welding on pressure equipment according to PED 2014 / 68 / EU

Pressure welder certificate according to EN-ISO 3834 - 2, EN 1090 - 2, EN 13480 - 1 to 5, EN 13445 - 1 to 5

DND-SFX

- Large magnetic separation area

- High processing capacity

- Magnetic flux: 5 800 G

Is a unique solution for the separation of ferrous particles from a dry or semi-liquid materials.

| Product | Maximum capacity (t/h) | Working width (mm) | Datasheet |

|---|---|---|---|

| DND-SFX 500 | 30 | 500 | display PDF |

Which industrial branches can the the automated plate magnet be used in?

The automatic magnetic separator DND-SFX represents a well-balanced alternative to expensive trunnion magnet separators and rotary trommel screens which are used in particular to clean materials coming out of ball mills (in the course of cement production, ore processing, coal crushing in thermal electric stations, foam glass manufacturing etc.).