Self-cleaning magnetic filters MSP-AC EKO

The self-cleaning pipeline separator MSP-AC EKO is designed to separate in the automatic way fine and even weakly magnetic particles from a flow of liquid or well permeable materials.

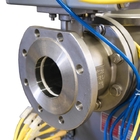

Design of the self-cleaning pipeline magnet

This simple, inexpensive, but at the same time highly effective pipeline magnetic filter consist of a stainless steel tube filled with neodymium magnets. This tube is inserted into a pipeline with horizontally flowing material, where it can catch even the smallest ferromagnetic particles and ensure a very high level of separation.

The trapped magnetic contaminants migrate to the rear of the tube where they do not block the material flow and remain protected from wash-off until the tubes are cleaned. Unlike small tubes (with diameters between 25 mm and 32 mm) of the standard magnetic strainers, the high-intensity magnetic filter MSP-AC EKO fitted with a very thick magnetic tube which improves the separation abilities of the appliance considerably (the magnetic core is very large and can generate very strong magnetic field) and at the same time the cleaning intervals are less frequent (on the bigger surface of the magnetic tube there can be held on the rear wall much more ferrous particles).

The automated magnetic filter MSP-AC EKO is fitted with extremely strong neodymium magnets in order to achieve as much effective magnetic separation as possible (it can reach a magnetic induction up to 9 500 G on the surface of the stainless steel protective tube).

Which way is the automated pipeline magnet cleaned?

In the course of the subsequent cleaning the product inlet and outlet are firstly automatically closed and afterwards the rinsing water inlet and outlet valves are opened. The neodymium magnetic core is automatically (in an interval pre-adjusted either mechanically or by a control unit) pulled out from the stainless steel tube into the upper part of the separator and the trapped magnetic particles are washed off the surface of the stainless steel tube by rinsing water into an auxiliary pipeline. The automatic cleaning is very fast, it does not require a presence of an operator and no undesirable downtimes occur.

In order to re-utilize the rinsing water in the best possible (economic as well and environmentally friendly) way, we could insert into the washing water circuit another magnetic separator (for separation of ferrous particles from the rinsing water) and arrange for a continuous utilization of the washing water (in the closed washing circuit of this automatic magnetic filter). The standard self-cleaning mode of the magnetic separator is ensured by pneumatic components with mechanically adjustable parameters (like the cleaning interval setting). For an extra charge, we could supply the separator with a fully programmable control unit and/or with a touchscreen control panel for a rapid and individual adjustment of the device to the currently needed use etc. The self-cleaning magnetic filter is designed to cope with nearly any contamination level and can be also incorporated into a fully automatic production line.

Further advantages of the self-cleaning magnetic filter

This kind of separator can be delivered also in a double wall jacketed version. The jacketed filters are used in heated pipeline applications where the temperature is critical to the product viscosity (i. e., the separator tempering prevents the cleaned products - such as chocolate, syrups, jams, sauces - from solidifying).

What pipeline is the automated magnetic filter connected to?

In the standard design, this appliance is manufactured with connection flanges from 50 mm to 100 mm. If necessary, the connecting dimensions and the method of connection to the piping system (standard flanges, JACOB flanges, threaded connections, special connection pieces) can be customized.

SOLLAU – our products are welded by real professionals!

SOLLAU certifications:

Authorization to perform welding on pressure equipment according to PED 2014 / 68 / EU

Pressure welder certificate according to EN-ISO 3834 - 2, EN 1090 - 2, EN 13480 - 1 to 5, EN 13445 - 1 to 5

- Separator is delivered without valves and flaps (the client arranges for them)

- Connecting diameters from 20 to 150 mm

- Small installation dimensions

Valveless version cleaned pneumatically. The material flowsa via the inlet pipework into the separator and Fe contaminants are caught on the stainlees surface of the magnetic tube. When cleaning the magnetic core is ejected pneumatically out of the cover stainless sheating and the impurities caught are rinsed. The way of rinsing and effluent of the impurities caught as well as stopping the material inflow etc. are solved by the customer herself or himself.

| Product | Connecting diameter (mm) | Datasheet |

|---|---|---|

| MSP-AC EKO 20 V0 BARRACUDA | 20 | display PDF |

| MSP-AC EKO 40 V0 BARRACUDA | 40 | display PDF |

| MSP-AC EKO 50 V0 BARRACUDA | 50 | display PDF |

| MSP-AC EKO 80 V0 BARRACUDA | 80 | display PDF |

| MSP-AC EKO 100 V0 BARRACUDA | 100 | display PDF |

| MSP-AC EKO 125 V0 BARRACUDA | 125 | display PDF |

| MSP-AC EKO 150 V0 BARRACUDA | 150 | display PDF |

- Separator is delivered with valves and flaps

- Fully automatic version

- Connecting diameters from 20 to 150 mm

- Control panel with a display

Four-valve version cleaned pneumatically. The material flows via the imńlet pipework into the separator and Fe impurities are caught on the stainless surface of the magnetic tubing. When cleaning the flow of material is stopped first, after that the cleaning valve is activated, the cleaning flows in into the separator, magnetic cores are ejected pneumatically and the Fe impurities are rinsed with a stream of cleaning liquid into the waste piping (output from the outfall line ca be used for taking of samples, too). Subsequently the magnet is pushed in into the basic position, inflow of the cleaning liquid is interrupted, the cleaning valve is deactivated and the normal operation is continued.

| Product | Connecting diameter (mm) | Datasheet |

|---|---|---|

| MSP-AC EKO 20 V4 BARRACUDA | 20 | display PDF |

| MSP-AC EKO 40 V4 BARRACUDA | 40 | display PDF |

| MSP-AC EKO 50 V4 BARRACUDA | 50 | display PDF |

| MSP-AC EKO 80 V4 BARRACUDA | 80 | display PDF |

| MSP-AC EKO 100 V4 BARRACUDA | 100 | display PDF |

| MSP-AC EKO 125 V4 BARRACUDA | 125 | display PDF |

| MSP-AC EKO 150 V4 BARRACUDA | 150 | display PDF |

Some products from this model family are available for immediate purchase. We are constantly extending the offer of our magnetic separators in stock so that we can deliver them to you immediately. Please, contact our dealer to inform for their current availability.

Which industrial branches can the automated magnetic filter be used in?

The highly hygienic design of this ferrous trap complies also with food industry requirements, however, the field of utilization of the self-cleaning magnetic filter MSP-AC EKO is much wider. It is used as an economic substitution for the standard expensive, large and complex separators with automatic cleaning and for that reason it is widely applied e. g. in the engineering, chemical and ceramic industries, in industrial cooling circuits etc.