Self-cleaning magnetic grate separators MSS-AC

Self-cleaning magnets are are designed to separate in a quick and easy way even the finest magnetic iron contamination from free-flowing substances of good bulk properties and to protect the machinery that subsequently treats these materials.

Benefits of using the separator

- Final material without iron contamination

- Permanent protection of production equipment

- Continuous production operation

- Automatic cleaning without interruption of the material flow at some models

- Elimination of operator errors

We are able to manufacture this magnetic separator with the maximum induction of 16 000 G on the core and 11 500 G on the magnetic pipe sheating. Tolerance is +/- 10 %.

Design and principle advantages of self-cleaning grate magnets

The self-cleaning drawer magnet consists of a set of several magnetic grates positioned above each other made of stainless steel equipped with alternately even and odd number of pipes. The magnetic sieve achieved in this way is in a very intensive contact with the streamy material and is capable of catching even the finest metal impurities and give a guarantee of the separation of a very high standard. The compact design made of DIN 1.4301 stainless steel ensures a simple and spatially undemanding building-in into the existing production lines and simultaneously it is a guarantee of high endurance and long service life of the entire system.

The key elements of this separator are magnetic rods in the stainless steel casing and inserted into one more protective stainless grate. This so called system „tube in tube“ has several advantages:

- within the framework of the not fully fair competitive struggle some competitive manufacturers boast about high induction on the surface of covering stainless pipes (up to 12 200 G), whereas they forget to mention that only ONE covering pipe is used at their separators, therefore in the case of its damage the client is exposed to the risk of contamination of the product being cleaned by dangerous snatches of the magnets. The magnetic systems used by us are extremely strong and in the reality we achieve magnetic induction of up to 16 000 G on the internal covering pipe (that closes the magnetic cores in a close shut way)! (which is a significantly higher value than the one achieved by our competitors on the surface of the covering pipes). But by purpose we hide the internal pipe in the grate-shaped separators made by our company with one more (external) covering stainless pipe that decreases the sequent induction in the area of contact with the material being cleaned to (still very high) value of approximately 11 500 G but (and it is a key issue for us) by this above all the guarantee of the absolute safeness is provided to the client (because it prevents from the penetration of the snatches of the magnetic cores into the material being cleaned in the case of eventual damage of the external covering pipe)

- the service life of the expensive magnetic cores is prolonged significantly thanks to the dual sheating (water cannot penetrate towards them, mechanic erosion of these does not occur during the cleaning etc.)

- endurance of the entire grate-shaped system against abrasion is increased

Which way is the self-cleaning magnetic separator cleaned?

The cleaning intervals can be electronically preset according to the actual contamination

Magnetic grate separator with automatic cleaning is fitted with very strong neo magnets and can capture even only weakly magnetic fragments (such as magnetic stainless steel). Thanks to the self-cleaning properties this magnetic grate separator can be installed also in fully automatized production line, what ensures a high effectiveness of the production process. The cleaning intervals can be electronically preset according to the actual contamination.

What pipeline is the separtor connected to?

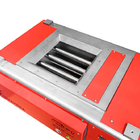

For purpose of the quick and simple application the box of separator ended with the flanges - - standard square flanges or with the ones of the Jacob type based on an individual requirement. We manufacture standardly the boxes of the mating dimensions from 180 x 180 to 630 x 630 mm but we are able to adjust the connection regarding the dimension and shape.

The process of separation can be monitored via a inspection window in the upper part of the separator at all types. Due to the high demands of food industry and pharmaceutical industry some parts of the separator entering the contact with the material being cleaned can be delivered in the polished design.

SOLLAU – our products are welded by real professionals!

SOLLAU certifications:

Authorization to perform welding on pressure equipment according to PED 2014 / 68 / EU

Pressure welder certificate according to EN-ISO 3834 - 2, EN 1090 - 2, EN 13480 - 1 to 5, EN 13445 - 1 to 5

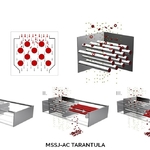

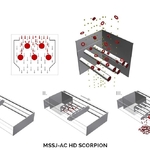

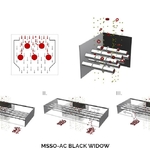

The self-cleaning grate magnet is produced in three versions: one-sided with continual cleaning (MSSJ-AC Tarantula), one-sided for discontinuous operation in troublesome conditions (MSSJ-AC HD Scorpion) and double-sided with continual cleaning (MSSO-AC Black Widow).

- Automatic cleaning without a need of interrupting the flow of material

- Four-stage separation

- Extremely large intercepting magnetic area

- Small dimensions

- Inspection opening

- Very attractive ratio ´´price/performance“

- Low repair and service costs

- Magnetic induction of up to 16 000 G

- ATEX (zone 22 outside of the equipment and zone 21 inside of the equipment)

- Five-year warranty for the magnetic core

MSSJ-AC TARANTULA separator for continuous operation (the hole for the material input is positioned at the edge of the separator)

At the throughs via the pipe grates the magnetic metal impurities are caught thanks to the strong permanent magnets on the surface of the stainless cover pipes. Subsequently both upper magnetic grids are moved above the waste hopper in the preconfigured intervals by air-operated drive and guiding roller bars and after that the magnetic cores consisting of stainless grids are drawn up to the extreme position (so above dust-exhaust provided the magnetic separator is equipped with optional appliance). After extrusion of magnetic cores the magnetic particles caught fall off spontaneously out of the surface of the pipes into the waste hopper. Provided the separator is equipped with a dust exhausting device (these are optional accessories) even the finest dust particles of the mass being cleaned are removed out of the magnetic cores pulled out by exhausting. The clean material (already free of ferro-magnetic impurities) falls to the hopper of the material being cleaned spontaneously after passing the magnetic grids and it is led away to be processed further.

After finishing the cleaning process the magnetic cores are intromitted back to the covering pipes and the cleaning process is repeated without a break in the preconfigured intervals (either both upper or both lower storeys of the separator are cleaned alternately). Automatic cleaning combined with smaller dimensions predetermine this device to be used in the production lines with a lack of area to carry out the required manual cleaning of the MSS-MC standard magnetic grate-shaped separator with manual cleaning or area to install the MSSO-AC Black Widow separator with automatic continual cleaning.

The magnetic sieve (consisting of four grates) ensures the high efficiency of separation and at the same time the cleaning intervals are prolonged due to it (because the large intercepting area sustains a big quantity of ferromagnetic particles). And even the separator contains four magnetic grates, an extremely low installation height has been achieved by a sophisticated structural design. The status of the separator can be checked continuously by the inspection chamber.

Specific advantages

- Continuous cleaning (= there is no need to interrupt the material flow during the cleaning)

- High stiffness of the sieve (4 storeys of magnetic pipes = more effective separation)

- Extremally large total magnetic catch area

- Reduced length of separator (= lower build-up area)

- Possibility to replace the individual magnetic bars (= lower repair and service costs)

- Inspection chamber to check the status of magnetic bars

- Attractive ratio of the parameters "price/performance"

| Product | Maximum capacity (m3/h) | Dimension of input/output (mm) | Datasheet |

|---|---|---|---|

| MSSJ-AC 200 TARANTULA | 10 | 200 x 200 | display PDF |

| MSSJ-AC 300 TARANTULA | 30 | 300 x 300 | display PDF |

| MSSJ-AC 400 TARANTULA | 50 | 400 x 400 | display PDF |

| MSSJ-AC 500 TARANTULA | 70 | 500 x 500 | display PDF |

| MSSJ-AC 600 TARANTULA | 90 | 600 x 600 | display PDF |

- Automatic cleaning with a need of interrupting the flow of material

- Separation of even uncommonly big fractions

- Robust construction

- Inspection opening

- Attractive ratio of the parametres "price/performance“

- Magnetic induction of up to 16 000 G

- ATEX (zone 22 outside of the equipment and zone 21 inside of the equipment)

- Five-year warranty for the magnetic core

MSSJ-AC HD-SCORPION separator for interrupted operation in demanding working conditions (hole for material input is positioned at the edge of the separator)

During the throughs through the pipe-type grids the magnetic metal impurities are caught on the surface of the stainless pipes thanks to the strong permanent magnets. Then the magnetic grid is moved above the waste hopper by the air-operated drive and bushing guides in the preconfigured intervals and after that the magnetic cores consisting of stainless pipes are pushed out up to the extreme position (so above the dust-exhausting appliance provided the magnetic separator is equipped with this optional appliance). After pushing out the magnetic cores the metal particles caught fall off spontaneously out of the surface of the cover pipes into the waste hopper. Provided the separator is equipped with a dust exhausting device (these are optional accessories), even the finest particles of the mass being cleaned are removed out of the pulled out metal cores in this position by exhausting. After passing the magnetic grids the clean material (already free of ferro-magnetic impurities) falls down spontaneously into the output of the clean material to be processed further.

After ending the cleaning process magnetic cores are intromitted into the covering pipes and the cleaning process is repeated in the preconfigured intervals. Automatic cleaning combined with smaller dimensions and robust structure of the separator predetermine this device e.g. to be used in the production lines processing rougher material, in the plant where there is not enough room to carry out the required manual cleaning of the MSS-MC standard magnetic grate-shaped separator with manual cleaning etc.

This separator is capable of processing the material and ferromagnetic contaminants in the uncommonly wide fractional spectrum (it separates both very soft ferromagnetic particles and also longer thin wires etc. that could block other types of grate-shaped separators). With regard to the prospective application in the demanding means of industry the sheating of both magnetic rods themselves and also the portective covering of the entire separator significantly more robust than at at other grate-shaped automatic machines. The status of the magnetic rods can be checked via an inspection openingr continuously.

Specific advantages

- Separator is able to process the material and ferro-magnetic contaminants in an unusually wide fraction spectrum

- Robust structure for more demanding industrial applications

- Inspection chamber to check the status of magnetic bars

- Attractive ratio of the parametres ´´price/performance“

| Product | Maximum capacity (m3/h) | Dimension of input/output (mm) | Datasheet | MSSJ-AC HD 200 SCORPION | 15 | 200 x 200 | display PDF |

|---|---|---|---|

| MSSJ-AC HD 300 SCORPION | 30 | 300 x 300 | display PDF |

| MSSJ-AC HD 400 SCORPION | 55 | 400 x 400 | display PDF |

| MSSJ-AC HD 500 SCORPION | 80 | 500 x 500 | display PDF |

- Automatic cleaning without a need of interrupting the flow of material

- Extremely large interceptive magnetic area of one rod

- Small loss of the primary material

- High capacity

- Option to replace only one unique magnetic rod

- Each magnetic rod has a driveline of its own

- Inspection chamber

- Service opening

- Protective stainless sieve

- Magnetic induction of up to 18 700 G

- ATEX (zone 22 outside of the equipment and zone 21 inside of the equipment)

- Five-year warranty for the magnetic core

MSSO-AC BLACK WIDOW separator for continuous operation (hole for material input is positioned in the centre part of the separator)

At the throughs through the tubular grids the magnetic metal impurities are caught on the surface of stainless pipes thanks to the strong permanent magnets. The tubular grids cover two thirds of the width of the separator and at the same time the magnetic cores occur below the gate for contaminated material. Thanks to the of the cover pipes the magnetic cores are permanently protected by the stainless cover pipes, whereas a half of the length of the cover pipes (i. e. the part that go beyond into the zone of actual cleaning) gets rid of the magnetic impurities permanently.

This gives the guarantee of the constituousness of both cleaning and also separation process (without the necessity to interrupt the production cycle in the course of magnetic separation). Each of the cover pipes of one (e. g. of the lower storey) storey is moved individually by an air-operated drive and guiding roll bars e.g. to the right and subsequently also the upper storey of the cover pipes will be moved into the same position in this way in the preconfigured intervals. The emptying of impurities caught on the surface of the cover pipes into the waste hopper on the right side mentioned takes place for the time of the cleaning interval preconfigured by the client. After finishing the cleaning interval the lower storey of the grid is moved to the left and after that it is followed by the upper storey.

MSSO-AC BLACK WIDOW is equipped with so called secondary cleaning zone reducing the material losses at the cleaning of the separator.

The sophisticated covering of this separator enables:

- to follow the status of contamination of the magnetic rods (via an inspection opening)

- to cary out the service without a need of disassembling the separator (thanks to the inspection opening)

Thanks to a unique technical solution this seprator can be applied also in the plants with an extremely high processing capacity (connecting hole of the dimension of up to 600 x 600 mm). At MSSO-AC BLACK WIDOW the individual magnetic rods are replaced (and not the whole grates), which brings the clients the financial and time savings at the service and repairs. In addition to this each magnetic rod has a driveline of its own therefore when one rod is disable stated all other rods work in a common way and there is no need of shutting down the separator). The protective stainless sieve protects the magnetic rods against the damage by the material being cleaned or by contaminants.

Specific advantages

- Continual cleaning (= there is no need to interrupt the material flow in the course of cleaning)

- Big diameter of the magnetic bars (= extremely large catching magnetic area of one bar)

- Secondary separation zone (= smaller losses of the primary material)

- Possibilty to replace the only magnetic bar

- Each magnetic bar has its own gearing (= at the disable state of one bar all others work in a normal way and there is no need to put the separator out of the service)

- The inspection chamber to check the status of magnetic bars

- Service opening (= to carry out the service without a need to disassemble the separator)

- Protective stainless sieve (= protecting the magnetic bars against abeing damaged by the primary material or contaminants)

| Product | Maximum capacity (m3/h) | Dimension of input/output (mm) | Datasheet |

|---|---|---|---|

| MSSO-AC 180 BLACK WIDOW | 7 | 180 x 180 | display PDF |

| MSSO-AC 270 BLACK WIDOW | 20 | 270 x 270 | display PDF |

| MSSO-AC 360 BLACK WIDOW | 35 | 360 x 360 | display PDF |

| MSSO-AC 450 BLACK WIDOW | 60 | 450 x 450 | display PDF |

| MSSO-AC 540 BLACK WIDOW | 85 | 540 x 540 | display PDF |

| MSSO-AC 630 BLACK WIDOW | 110 | 630 x 620 | display PDF |