Plate magnet MS-MC-K/S

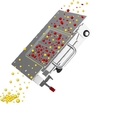

The exposed pole plate magnet MS-MC-K/S is a simple but highly efficient magnetic separator with a very wide range of applications. Most often, the magnetic plate is installed in chutes, spouts, ducts or pipes to remove ferrous fine particles and larger pieces of tramp iron from various types of bulk materials. It is suitable above all for the applications where a more sophisticated magnetic separator (e.g., due to the limited installation space or because of the already existing production technology) cannot be placed. You simply cut a hole in the existing pipeline and insert the magnetic door.

Thanks to its advantageous price, the magnetic plate is a very popular type of the magnetic separator. We equip this „magnetic door“ with very strong neodymium magnets, achieving high efficiency of the magnetic separation.

The plate magnet door is also suitable for abrasive or poorly permeable materials, as no obstacle (e.g., a magnetic grate) is inserted into the material flow which would block it or could be damaged by the abrasive material.

Separator design

The plate magnet consists of two parts:

- the magnetic core

- the stainless steel easy clean plate

We produce the plate magnets in two model lines which differ only in the cleaning mode.

Customer care

Your project will be taken care of by us from beginning up to the very end. It does not end with the order placed at us. We will provide the full support for all the time of the use of the separator.

1. We will come

2. We will align and design

3. We will make a made-to-measure product

4. We will install

5. We will put into operation and school in

6. We will provide authorized service

We guarantee tests withing three days!

Make sure that our device perfectly meets your expectations!

We will provide tests of your material on our magnetic separators for FREE!

SOLLAU – our products are welded by real professionals!

SOLLAU certifications:

Authorization to perform welding on pressure equipment according to PED 2014 / 68 / EU

Pressure welder certificate according to EN-ISO 3834 - 2, EN 1090 - 2, EN 13480 - 1 to 5, EN 13445 - 1 to 5

- Cleaned by tilting the plate magnet

- As a standard 4 500 G (optionally up to 7 000 G) at the point of contact with the processed material

- Resistant all-stainless steel design

We recommend that the tiltable plate magnet is used especially if there is enough space for the operator as well as for tilting the magnetic door. If there is not sufficient space, we recommend using the side sliding magnetic door.

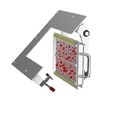

How is cleaned the tiltable plate magnet

When the material flow is stopped, release the lock and tumble out the magnetic door. In the following step, move the magnetic core from the cleanout panel and the ferrous metals (trapped on the stainless cleanout panel) will fall off. The plate magnet of this type is suitable for places with sufficient handling space.

| Product | Weight (kg) | Dimension of input/output (mm) | Datasheet |

|---|---|---|---|

| MS-MC-K 200x200 N | 21 | 200 x 200 | display PDF |

| MS-MC-K 300x200 N | 26 | 300 x 200 | display PDF |

| MS-MC-K 400x250 N | 43 | 400 x 250 | display PDF |

| MS-MC-K 500x250 N | 52 | 500 x 250 | display PDF |

| MS-MC-K 600x300 N | 69 | 600 x 300 | display PDF |

- Cleaned by sliding the plate magnet aside

- For hard-to-reach places

- As a standard 4 500 G (optionally up to 7 000 G) at the point of contact with the processed material

- Resistant all-stainless steel design

The side sliding magnetic door is a great solution if there is not enough space to clean the plate magnet by tilting (e.g. the pipe is installed close to the wall, near another pipe etc.). In this case, we recommend that the withdrawable magnetic door is used (whose magnetic core can be slid aside).

How is cleaned the side sliding magnetic door

When the material flow is stopped, release the lock and tumble out the magnetic door. In the following step, slide the magnetic core aside and the iron particles (gathered on the stainless cleanout panel) will fall off. The plate magnet of this type is suitable for places with insufficient handling space.

| Product | Weight (kg) | Dimension of input/output (mm) | Datasheet |

|---|---|---|---|

| MS-MC-S 200x200 N | 18 | 200 x 200 | display PDF |

| MS-MC-S 300x200 N | 24 | 300 x 200 | display PDF |

| MS-MC-S 400x250 N | 39 | 400 x 250 | display PDF |

| MS-MC-S 500x250 N | 48 | 500 x 250 | display PDF |

| MS-MC-S 600x300 N | 65 | 600 x 300 | display PDF |

Which industrial branches can the plate magnet be used in?

The plate magnet finds its application in the food processing industry, fodder production, pharmaceutical industry, wood processing, chemical and ceramic industries etc.