Vibrating Sieves

Virto Cuccolini’s vibrating sieves are featured for their high quality and reliability. We have a product for practically every application where sieving is required.

We take pride in superior technical and customer support.

Our experienced experts will recommend you the most suitable vibrating sieve for your application.

Tell us more details about your project - we can help you choose the right vibrating sieve.

Virto-Cuccolini’s vibrating sieves - separation technology for all industries

In the Food Industry

They ensure the safe sieving of flour, sugar, or cocoa, remove lumps from milk powders, and separate biomasses such as spirulina from water.

In Recycling

They sort PET flakes, ground e-waste, and crushed glass. At the same time, they purify process water, thereby supporting the circular economy.

In the Chemical and Plastics Industry

The sieves control the grain size of PVC powders, remove dust from re-granulates, and ensure fine sorting of pigments for coating compositions.

In Building Industries

Vibrating sieves monitor the size curve of sand, cement, and ceramic mixtures, dewater mining sludges, and recycle glazes for ceramics.

Comprehensive solutions from SOLLAU - magnetic separators, metal detectors, vibrating sieves, and vibrating feeders - all in one place!

Sieving is an industrial process mainly used to:

- Removal of unwanted particles (larger, e.g. lumps, foreign objects; or smaller, e.g. dust) from powdered or granular materials.

- Material fractionation according to particle size.

- Material dewatering by separating the solid component from water.

WHY IS SIEVING USED IN PRODUCTION PROCESSES?

- Security: It prevents the entry of unwanted particles into the final product (e.g. in the food industry and 3D printing), thus meeting legislative requirements and ensuring quality.

- Quality: It allows the material to be separated into different fractions according to particle size. This creates products with different properties and market opportunities (e.g. in food processing, metallurgy, and building industries).

- Recovery (recycling): It enables the effective recycling of waste materials and their reusing as valuable products following the principles of circular economy.

Technical applications of sieving include: Dedusting (removal of fine particles), Security sieving (removal of larger particles), and Classification (sorting according to particle size).

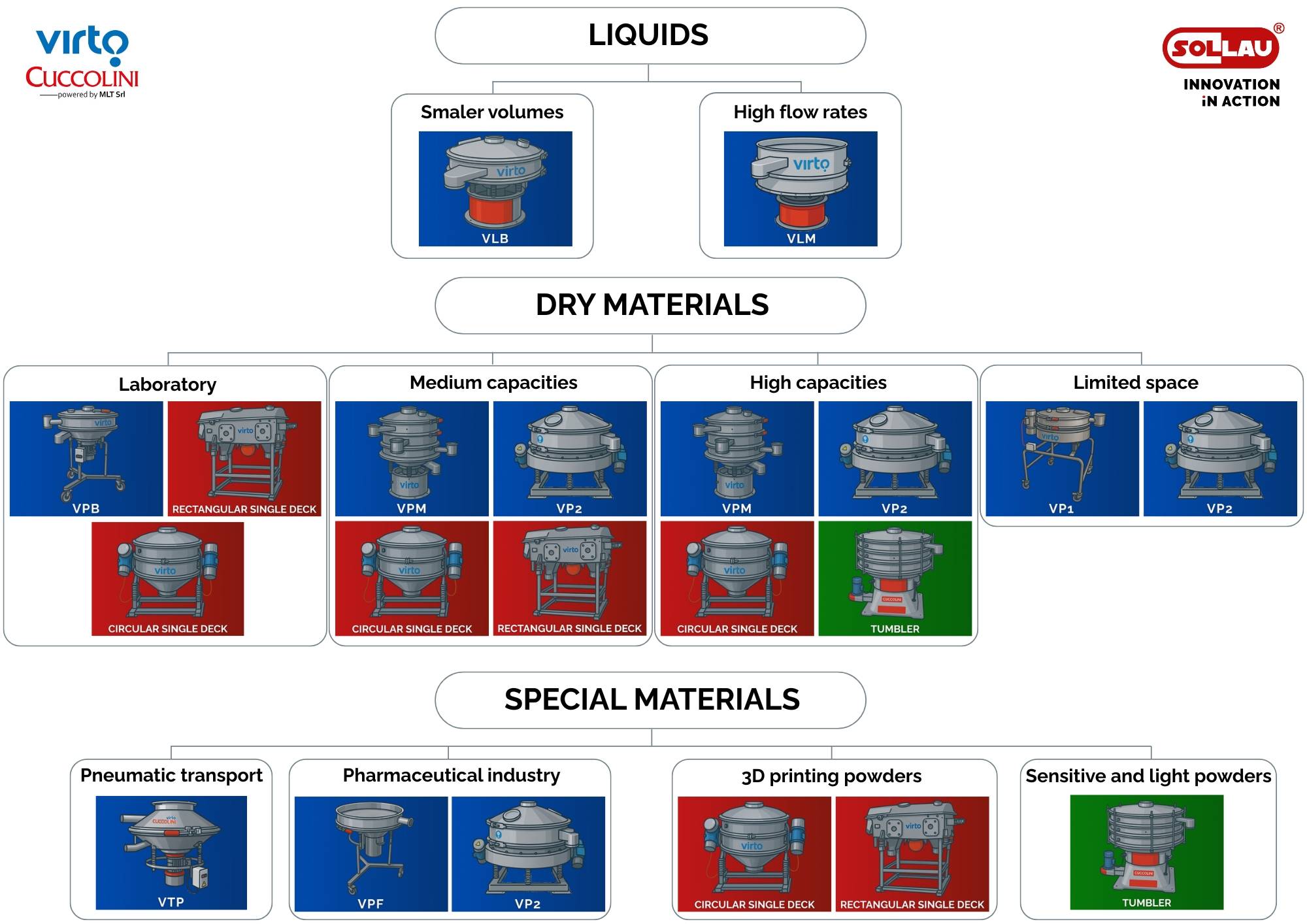

Select the appropriate sieving technology: The C-Line, X-Line, or T-Line vibrating sieves?

Differences between the products C-Line, X-Line, and T-Line vibrating sieves

Each product line of vibrating sieves offers specific advantages for different applications and materials:

The C-Line Vibrating Sieves

Versatile professional vibrating sieves for wide industrial use, from powders and bulk mixtures to liquids. The C-Line series uses traditional single-frequency vibration technology to cover the most common applications (check sieving, classification, dedusting, and dewatering of liquids containing solids).

The C-Line models

- VTP - Vibrating sieve for pneumatic transport

- VLB/VLM - Vibrating sieves for liquids and pasty mixtures

- VP1 - single-motor high-capacity vibrating sieve

- VP2 - single-motor high-capacity vibrating sieve

- VPF/VPF2 - vibrating sieves for the pharmaceutical industry

- VPB/VPM - vibrating sieves for powders and bulk materials

The X-Line Vibrating Sieves

Multi-frequency vibrating sieves are designed for extremely demanding applications, especially for fine, sticky, or abrasive materials. The X-Line series uses patented multi-frequency technology. This technology can solve the critical sieving problems of the most demanding applications, both for powders and liquids containing solid particles (dewatering applications).

The X-Line models

- CIRCULAR SINGLE DECK - vibrating sieve for extremely demanding applications

- RECTANGULAR SINGLE DECK - vibrating sieve for extremely demanding applications

The T-Line vibrating sieves

Tumbler vibrating sieves with gentle particle movement are aimed at sorting and dedusting fine, sensitive, and non-sticky materials. The T-Line range is suitable for applications requiring high capacity and sorting efficiency - for particles from 100 microns in dry processes. Thanks to their unique three-dimensional motion, they achieve up to 99% efficiency without damaging particles.

The T-Line models

- T-LINE TUMBLER - vibrating sieves for powder materials

Tell us more details about your project - we can help you choose the right vibrating sieve.

How to choose the right vibrating sieve?

Selection of the right screen depends on the type of material, the required capacity, the space, and the industry branch.

Depending on the sieve size and capacity

| Sieve size | Recommended models |

|---|---|

| Small sieves (450–800 mm) | VPB, VPF, VP2 (smaller models) and X-Line SD |

| Middle sieves (900–1,200 mm) | VLM, VPM, VP2, T-Line VTU 900–1200 and X-Line circular |

| Large sieves (1,500–2,000 mm) | VPM, VP2 (larger models), T-Line VTU 1500–2400 and X-Line RS |

Frequently asked questions (FAQ) – C-Line, X-Line, T-Line vibrating sieves

Looking for the ideal vibrating sieve for your operation? We have prepared an overview of the most common FAQs about the C-Line, X-Line, and T-Line series to help you navigate our offer. You will quickly find answers to key questions and find out which solution is right for you.

Have a question?

Are you interested in the possibility of using Virto Cuccolini’s vibrating sieves?

Would you like to discuss modifications, customizations, or pricing?

Write to us and we will get back to you within 24 hours.