Conveyor head rollers MV / Magnetic pulleys

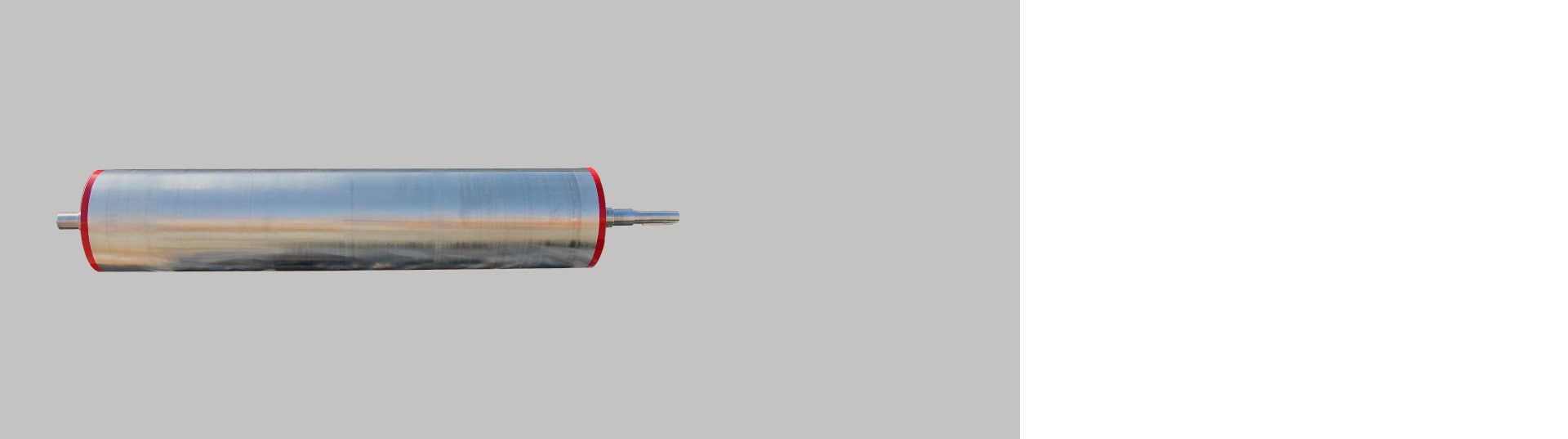

A magnetic pulley (sometimes called also a magnetic roller) is a device for automatic and permanent removal of magnetic iron metals from inert materials.

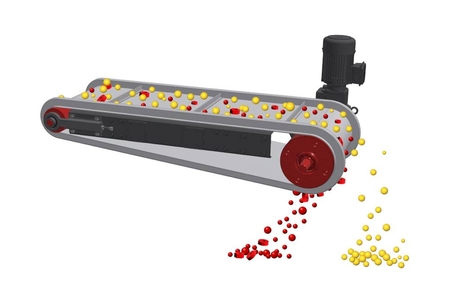

Installation of the pulley magnet

The key part of the machine consists of a set of ferrite or neodymium NdFeB magnets and of an external drum from stainless steel that revolves on a shaft together with the magnetic cores. The magnetic pulley is usually an integral part of a belt conveyor (unlike the magnetic drum).

How does the magnetic head pulley work?

The ferromagnetic pieces (transported on the conveyor belt) are captured by the strong permanent magnets and dragged on the surface of the pulley beyond the magnetic axis of the drum where they fall off (already before that the non-magnetic particles fall off due to gravity).

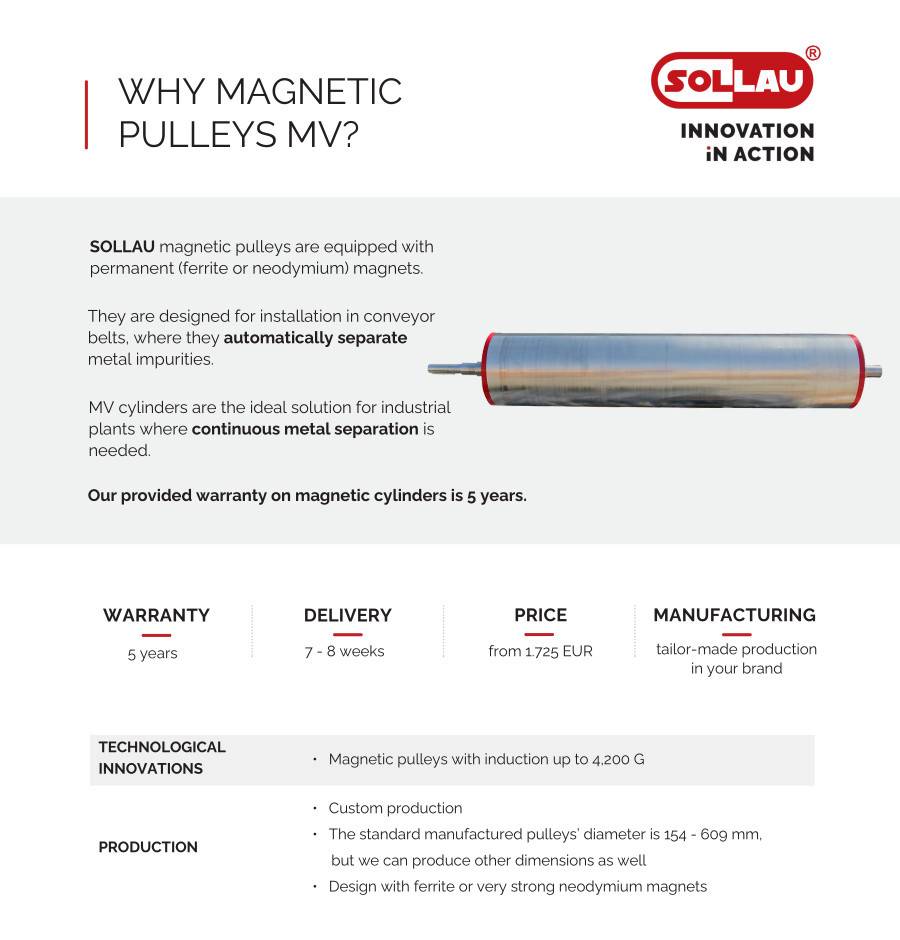

Why magnetic pulleys by SOLLAU?

Why magnetic pulleys by SOLLAU?

Download PDF

(Size 704 kB)

Customer care

Your project will be taken care of by us from beginning up to the very end. It does not end with the order placed at us. We will provide the full support for all the time of the use of the separator.

1. We will come

2. We will align and design

3. We will make a made-to-measure product

4. We will install

5. We will put into operation and school in

6. We will provide authorized service

We guarantee tests withing three days!

Make sure that our device perfectly meets your expectations!

We will provide tests of your material on our magnetic separators for FREE!

Recommendation

The magnetic field of the separation pulley is about 100 mm high, so it is advisable that the layer of the substance on the band should not be higher than 80 mm. In case of a high layer of the transported stuff we recommend to combine the use of the magnetic separation pulley with the application of our overband separator or our magnetic plate.

Advantages of the magnetic pulley

The magnetic pulley is easy to install and maintain, the materials used for its production (stainless steel, set of permanent ferrite or neo magnets) as well as its robust design provide for a long-term solution to separation problems.

The application of ferrite magnets arranges for nearly unlimited working life, however, if you need higher magnetic force we recommend that the drum is fitted with extremely powerful neodymium NdFeB magnets from rare earth ores (especially in case of the separation of small ferromagnetic particles from materials of worse bulk properties).

SOLLAU – our products are welded by real professionals!

SOLLAU certifications:

Authorization to perform welding on pressure equipment according to PED 2014 / 68 / EU

Pressure welder certificate according to EN-ISO 3834 - 2, EN 1090 - 2, EN 13480 - 1 to 5, EN 13445 - 1 to 5

MV 154

- Magnetic pulley diameter: 154 mm

- Up to 2 900 Gauss on the pulley surface

Ferrite version

| Product | Maximum capacity (m3/h) | Suitable width of conveyor belt (mm) | Roller diameter (mm) | Magnet type | Datasheet |

|---|---|---|---|---|---|

| MV 154 F 200 | 15 | 200 | 154 | Ferit | display PDF |

| MV 154 F 300 | 20 | 300 | 154 | Ferit | display PDF |

| MV 154 F 400 | 25 | 400 | 154 | Ferit | display PDF |

| MV 154 F 500 | 30 | 500 | 154 | Ferit | display PDF |

| MV 154 F 600 | 35 | 600 | 154 | Ferit | display PDF |

| MV 154 F 700 | 40 | 700 | 154 | Ferit | display PDF |

| MV 154 F 800 | 45 | 800 | 154 | Ferit | display PDF |

| MV 154 F 900 | 50 | 900 | 154 | Ferit | display PDF |

| MV 154 F 1000 | 60 | 1000 | 154 | Ferit | display PDF |

Neodymium version

| Product | Maximum capacity (m3/h) | Suitable width of conveyor belt (mm) | Roller diameter (mm) | Magnet type | Datasheet |

|---|---|---|---|---|---|

| MV 154 N 200 | 15 | 200 | 154 | Neodym | display PDF |

| MV 154 N 300 | 20 | 300 | 154 | Neodym | display PDF |

| MV 154 N 400 | 25 | 400 | 154 | Neodym | display PDF |

| MV 154 N 500 | 30 | 500 | 154 | Neodym | display PDF |

| MV 154 N 600 | 35 | 600 | 154 | Neodym | display PDF |

| MV 154 N 700 | 40 | 700 | 154 | Neodym | display PDF |

| MV 154 N 800 | 45 | 800 | 154 | Neodym | display PDF |

| MV 154 N 900 | 50 | 900 | 154 | Neodym | display PDF |

| MV 154 N 1000 | 60 | 1000 | 154 | Neodym | display PDF |

MV 204

- Magnetic pulley diameter: 204 mm

- Up to 3 700 Gauss on the pulley surface

Ferrite version

| Product | Maximum capacity (m3/h) | Suitable width of conveyor belt (mm) | Roller diameter (mm) | Magnet type | Datasheet |

|---|---|---|---|---|---|

| MV 204 F 200 | 20 | 200 | 204 | Ferit | display PDF |

| MV 204 F 300 | 25 | 300 | 204 | Ferit | display PDF |

| MV 204 F 400 | 30 | 400 | 204 | Ferit | display PDF |

| MV 204 F 500 | 35 | 500 | 204 | Ferit | display PDF |

| MV 204 F 600 | 40 | 600 | 204 | Ferit | display PDF |

| MV 204 F 700 | 45 | 700 | 204 | Ferit | display PDF |

| MV 204 F 800 | 50 | 800 | 204 | Ferit | display PDF |

| MV 204 F 900 | 60 | 900 | 204 | Ferit | display PDF |

| MV 204 F 1000 | 75 | 1000 | 204 | Ferit | display PDF |

Neodymium version

| Product | Maximum capacity (m3/h) | Suitable width of conveyor belt (mm) | Roller diameter (mm) | Magnet type | Datasheet |

|---|---|---|---|---|---|

| MV 204 N 200 | 20 | 200 | 204 | Neodym | display PDF |

| MV 204 N 300 | 25 | 300 | 204 | Neodym | display PDF |

| MV 204 N 400 | 30 | 400 | 204 | Neodym | display PDF |

| MV 204 N 500 | 35 | 500 | 204 | Neodym | display PDF |

| MV 204 N 600 | 40 | 600 | 204 | Neodym | display PDF |

| MV 204 N 700 | 45 | 700 | 204 | Neodym | display PDF |

| MV 204 N 800 | 50 | 800 | 204 | Neodym | display PDF |

| MV 204 N 900 | 60 | 900 | 204 | Neodym | display PDF |

| MV 204 N 1000 | 75 | 1000 | 204 | Neodym | display PDF |

MV 219

- Magnetic pulley diameter 219 mm

- Up to 3 700 Gauss on the pulley surface

Ferrite version

| Product | Maximum capacity (m3/h) | Suitable width of conveyor belt (mm) | Roller diameter (mm) | Magnet type | Datasheet |

|---|---|---|---|---|---|

| MV 219 F 200 | 20 | 200 | 219 | Ferrite | display PDF |

| MV 219 F 300 | 25 | 300 | 219 | Ferrite | display PDF |

| MV 219 F 400 | 30 | 400 | 219 | Ferrite | display PDF |

| MV 219 F 500 | 35 | 500 | 219 | Ferrite | display PDF |

| MV 219 F 600 | 40 | 600 | 219 | Ferrite | display PDF |

| MV 219 F 700 | 45 | 700 | 219 | Ferrite | display PDF |

| MV 219 F 800 | 50 | 800 | 219 | Ferrite | display PDF |

| MV 219 F 900 | 55 | 900 | 219 | Ferrite | display PDF |

| MV 219 F 1000 | 60 | 1000 | 219 | Ferrite | display PDF |

| MV 219 F 1100 | 65 | 1100 | 219 | Ferrite | display PDF |

| MV 219 F 1200 | 70 | 1200 | 219 | Ferrite | display PDF |

| MV 219 F 1300 | 75 | 1300 | 219 | Ferrite | display PDF |

| MV 219 F 1400 | 80 | 1400 | 219 | Ferrite | display PDF |

| MV 219 F 1500 | 85 | 1500 | 219 | Ferrite | display PDF |

Neodymium version

| Product | Maximum capacity (m3/h) | Suitable width of conveyor belt (mm) | Roller diameter (mm) | Magnet type | Datasheet |

|---|---|---|---|---|---|

| MV 219 N 200 | 20 | 200 | 219 | Neodym | display PDF |

| MV 219 N 300 | 25 | 300 | 219 | Neodym | display PDF |

| MV 219 N 400 | 30 | 400 | 219 | Neodym | display PDF |

| MV 219 N 500 | 35 | 500 | 219 | Neodym | display PDF |

| MV 219 N 600 | 40 | 600 | 219 | Neodym | display PDF |

| MV 219 N 700 | 45 | 700 | 219 | Neodym | display PDF |

| MV 219 N 800 | 50 | 800 | 219 | Neodym | display PDF |

| MV 219 N 900 | 55 | 900 | 219 | Neodym | display PDF |

| MV 219 N 1000 | 60 | 1000 | 219 | Neodym | display PDF |

| MV 219 N 1100 | 65 | 1100 | 219 | Neodym | display PDF |

| MV 219 N 1200 | 70 | 1200 | 219 | Neodym | display PDF |

| MV 219 N 1300 | 75 | 1300 | 219 | Neodym | display PDF |

| MV 219 N 1400 | 80 | 1400 | 219 | Neodym | display PDF |

| MV 219 N 1500 | 85 | 1500 | 219 | Neodym | display PDF |

MV 254

- Magnetic pulley diameter: 254 mm

- Up to 3 700 Gauss on the pulley surface

Ferrite version

| Product | Maximum capacity (m3/h) | Suitable width of conveyor belt (mm) | Roller diameter (mm) | Magnet type | Datasheet |

|---|---|---|---|---|---|

| MV 254 F 200 | 20 | 200 | 254 | Ferit | display PDF |

| MV 254 F 300 | 25 | 300 | 254 | Ferit | display PDF |

| MV 254 F 400 | 30 | 400 | 254 | Ferit | display PDF |

| MV 254 F 500 | 35 | 500 | 254 | Ferit | display PDF |

| MV 254 F 600 | 40 | 600 | 254 | Ferit | display PDF |

| MV 254 F 700 | 45 | 700 | 254 | Ferit | display PDF |

| MV 254 F 800 | 50 | 800 | 254 | Ferit | display PDF |

| MV 254 F 900 | 60 | 900 | 254 | Ferit | display PDF |

| MV 254 F 1000 | 75 | 1000 | 254 | Ferit | display PDF |

Some products from this model family are available for immediate purchase. We are constantly extending the offer of our magnetic separators in stock so that we can deliver them to you immediately. Please, contact our dealer to inform for their current availability.

Neodymium version

| Product | Maximum capacity (m3/h) | Suitable width of conveyor belt (mm) | Roller diameter (mm) | Magnet type | Datasheet |

|---|---|---|---|---|---|

| MV 254 N 200 | 20 | 200 | 254 | Neodym | display PDF |

| MV 254 N 300 | 25 | 300 | 254 | Neodym | display PDF |

| MV 254 N 400 | 30 | 400 | 254 | Neodym | display PDF |

| MV 254 N 500 | 35 | 500 | 254 | Neodym | display PDF |

| MV 254 N 600 | 40 | 600 | 254 | Neodym | display PDF |

| MV 254 N 700 | 45 | 700 | 254 | Neodym | display PDF |

| MV 254 N 800 | 50 | 800 | 254 | Neodym | display PDF |

| MV 254 N 900 | 60 | 900 | 254 | Neodym | display PDF |

| MV 254 N 1000 | 75 | 1000 | 254 | Neodym | display PDF |

MV 304

- Magnetic pulley diameter: 304 mm

- Up to 4 200 Gauss on the pulley surface

Ferrite version

| Product | Maximum capacity (m3/h) | Suitable width of conveyor belt (mm) | Roller diameter (mm) | Magnet type | Datasheet |

|---|---|---|---|---|---|

| MV 304 F 200 | 15 | 200 | 304 | Ferit | display PDF |

| MV 304 F 300 | 25 | 300 | 304 | Ferit | display PDF |

| MV 304 F 400 | 35 | 400 | 304 | Ferit | display PDF |

| MV 304 F 500 | 45 | 500 | 304 | Ferit | display PDF |

| MV 304 F 600 | 55 | 600 | 304 | Ferit | display PDF |

| MV 304 F 700 | 65 | 700 | 304 | Ferit | display PDF |

| MV 304 F 800 | 75 | 800 | 304 | Ferit | display PDF |

| MV 304 F 900 | 85 | 900 | 304 | Ferit | display PDF |

| MV 304 F 1000 | 95 | 1000 | 304 | Ferit | display PDF |

Neodymium version

| Product | Maximum capacity (m3/h) | Suitable width of conveyor belt (mm) | Roller diameter (mm) | Magnet type | Datasheet |

|---|---|---|---|---|---|

| MV 304 N 200 | 15 | 200 | 304 | Neodym | display PDF |

| MV 304 N 300 | 25 | 300 | 304 | Neodym | display PDF |

| MV 304 N 400 | 35 | 400 | 304 | Neodym | display PDF |

| MV 304 N 500 | 45 | 500 | 304 | Neodym | display PDF |

| MV 304 N 600 | 55 | 600 | 304 | Neodym | display PDF |

| MV 304 N 700 | 65 | 700 | 304 | Neodym | display PDF |

| MV 304 N 800 | 75 | 800 | 304 | Neodym | display PDF |

| MV 304 N 900 | 85 | 900 | 304 | Neodym | display PDF |

| MV 304 N 1000 | 95 | 1000 | 304 | Neodym | display PDF |

MV 406

- Magnetic pulley diameter: 406 mm

- Up to 4 200 Gauss on the pulley surface

Ferrite version

| Product | Maximum capacity (m3/h) | Suitable width of conveyor belt (mm) | Roller diameter (mm) | Magnet type | Datasheet |

|---|---|---|---|---|---|

| MV 406 F 300 | 35 | 300 | 406 | Ferit | display PDF |

| MV 406 F 400 | 45 | 400 | 406 | Ferit | display PDF |

| MV 406 F 500 | 55 | 500 | 406 | Ferit | display PDF |

| MV 406 F 600 | 65 | 600 | 406 | Ferit | display PDF |

| MV 406 F 700 | 75 | 700 | 406 | Ferit | display PDF |

| MV 406 F 800 | 90 | 800 | 406 | Ferit | display PDF |

| MV 406 F 900 | 120 | 900 | 406 | Ferit | display PDF |

| MV 406 F 1000 | 140 | 1000 | 406 | Ferit | display PDF |

Neodymium version

| Product | Maximum capacity (m3/h) | Suitable width of conveyor belt (mm) | Roller diameter (mm) | Magnet type | Datasheet |

|---|---|---|---|---|---|

| MV 406 N 300 | 35 | 300 | 406 | Neodym | display PDF |

| MV 406 N 400 | 45 | 400 | 406 | Neodym | display PDF |

| MV 406 N 500 | 55 | 500 | 406 | Neodym | display PDF |

| MV 406 N 600 | 65 | 600 | 406 | Neodym | display PDF |

| MV 406 N 700 | 75 | 700 | 406 | Neodym | display PDF |

| MV 406 N 800 | 90 | 800 | 406 | Neodym | display PDF |

| MV 406 N 900 | 120 | 900 | 406 | Neodym | display PDF |

| MV 406 N 1000 | 140 | 1000 | 406 | Neodym | display PDF |

MV 506

- Magnetic pulley diameter: 506 mm

- Up to 4 200 Gauss on the pulley surface

Ferrite version

| Product | Maximum capacity (m3/h) | Suitable width of conveyor belt (mm) | Roller diameter (mm) | Magnet type | Datasheet |

|---|---|---|---|---|---|

| MV 506 F 300 | 45 | 300 | 506 | Ferit | display PDF |

| MV 506 F 400 | 55 | 400 | 506 | Ferit | display PDF |

| MV 506 F 500 | 70 | 500 | 506 | Ferit | display PDF |

| MV 506 F 600 | 85 | 600 | 506 | Ferit | display PDF |

| MV 506 F 700 | 105 | 700 | 506 | Ferit | display PDF |

| MV 506 F 800 | 125 | 800 | 506 | Ferit | display PDF |

| MV 506 F 900 | 145 | 900 | 506 | Ferit | display PDF |

| MV 506 F 1000 | 180 | 1000 | 506 | Ferit | display PDF |

Neodymium version

| Product | Maximum capacity (m3/h) | Suitable width of conveyor belt (mm) | Roller diameter (mm) | Magnet type | Datasheet |

|---|---|---|---|---|---|

| MV 506 N 300 | 45 | 300 | 506 | Neodym | display PDF |

| MV 506 N 400 | 55 | 400 | 506 | Neodym | display PDF |

| MV 506 N 500 | 70 | 500 | 506 | Neodym | display PDF |

| MV 506 N 600 | 85 | 600 | 506 | Neodym | display PDF |

| MV 506 N 700 | 105 | 700 | 506 | Neodym | display PDF |

| MV 506 N 800 | 125 | 800 | 506 | Neodym | display PDF |

| MV 506 N 900 | 145 | 900 | 506 | Neodym | display PDF |

| MV 506 N 1000 | 165 | 1000 | 506 | Neodym | display PDF |

MV 609

- Magnetic pulley diameter: 609 mm

- Up to 4 200 Gauss on the pulley surface

Ferrite version

| Product | Maximum capacity (m3/h) | Suitable width of conveyor belt (mm) | Roller diameter (mm) | Magnet type | Datasheet |

|---|---|---|---|---|---|

| MV 609 F 300 | 55 | 300 | 609 | Ferit | display PDF |

| MV 609 F 400 | 70 | 400 | 609 | Ferit | display PDF |

| MV 609 F 500 | 85 | 500 | 609 | Ferit | display PDF |

| MV 609 F 600 | 100 | 600 | 609 | Ferit | display PDF |

| MV 609 F 700 | 150 | 700 | 609 | Ferit | display PDF |

| MV 609 F 800 | 190 | 800 | 609 | Ferit | display PDF |

| MV 609 F 900 | 205 | 900 | 609 | Ferit | display PDF |

| MV 609 F 1000 | 220 | 1000 | 609 | Ferit | display PDF |

Why magnetic pulleys by SOLLAU?

Why magnetic pulleys by SOLLAU?

Download PDF

(Size 704 kB)

Which industrial branches can the magnetic head pulley be used in?

The permanent magnet systems simplifies the separation of ferrous particles, allowing for automatic recovery without production stoppage. At the same time the magnetic roller protects the subsequent machinery (e. g., shredders, mills, grinders) from breakage. The magnetic pulleys find use in recycling and mining as well as in wood and plastic industries.

Recycling and waste processing

Machining and foundry industry

Paper industry

Tobacco industry

Textile industry

Ceramic and glass industry

Mining and quarrying industry

Cement and lime industry

Chemical industry, paints and lacquers

Automotive industry

Food processing industry

Wood industry

Plastics and rubber industries

Thermal power plants