The DND-AC overband magnet

The DND-AC overband magnet is an efficient and automatic solution for separating ferromagnetic impurities from dry materials transported on a conveyor. We produce separators with ferrite and strongest neodymium magnets.

- 10-year warranty

- Installation height up to 500 mm

- Tailored solution - 12 model series

- All stainless steel design = high durability

We will test your material within 3 days – free of charge

Advantages of DND-AC Overband Magnets from SOLLAU

Zero blind spots

No gap between magnetic core and sidewall = no unwanted metals under the belt.

Wide usage

Ideal for metal separation in the mining, recycling, energy, construction, and woodworking industries.

Fast delivery

We deliver overband magnets with a delivery time of 7 - 8 weeks.

Warranty and service

10-year warranty and guaranteed service intervention within 2 working days.

The DND-AC overband magnets - the high-end solution for the automatic separation of ferromagnetic impurities from materials conveyed by conveyor belts.

They are available with ferrite and extremely strong neodymium magnets and allow for transverse or longitudinal suspension, depending on the type of operation.

There are 12 model ranges for standard and demanding applications, including the affordable DND-AC ECO series.

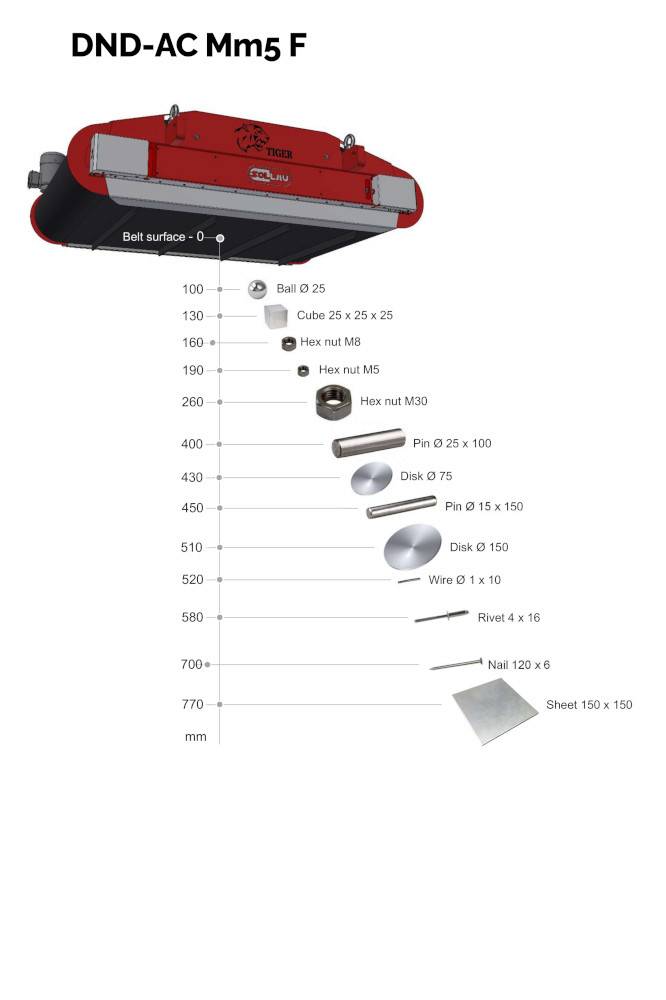

The overband magnets effectively separate metallic impurities with a size from 0.5 to 300 mm. These metals can be captured from heights up to 500 mm (ferrite) or 380 mm (neodymium) and feature robust stainless steel construction, high efficiency, and durability.

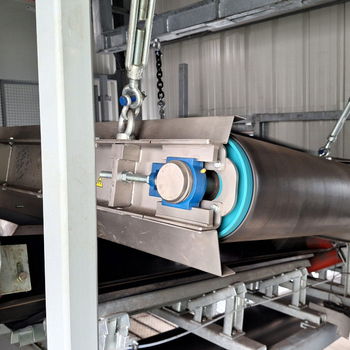

Thanks to a wide range of supplementary equipment (e.g., guide rollers, central lubrication, sliding rails), the overband magnets can be tailored to specific conditions.

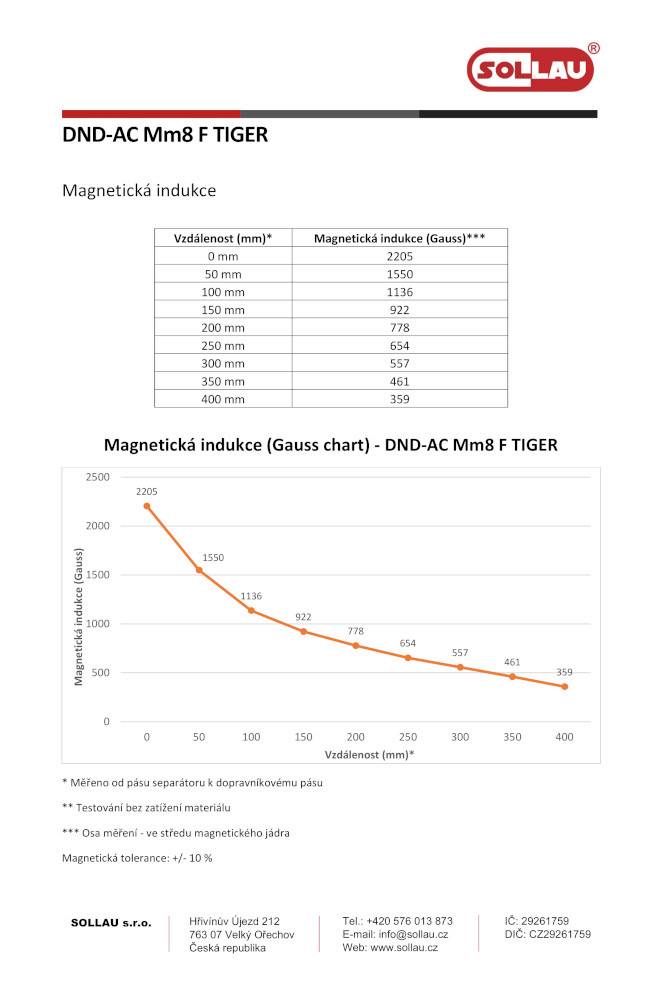

Standard procedure includes testing every unit – along with magnetic induction measurement (Gauss charts). We understand how important it is to know what types of impurities the separator can capture and from what height – that is why we transparently provide data on Fe impurity capture.

DND-AC overband magnets are mainly used in the mining, recycling, energy, construction, and wood processing industries.

Two types of DND-AC overband magnets

DND-AC overband magnets with FERRITE MAGNETS

- Suitable for common applications

- Lower acquisition costs

- Installation height up to 500 mm

- 8 Model ranges

DND-AC overband magnets with NEODYMIUM MAGNETS

- Extremely strong (but relatively short) magnetic field

- Low weight

- Installation height up to 380 mm

- 4 Model ranges

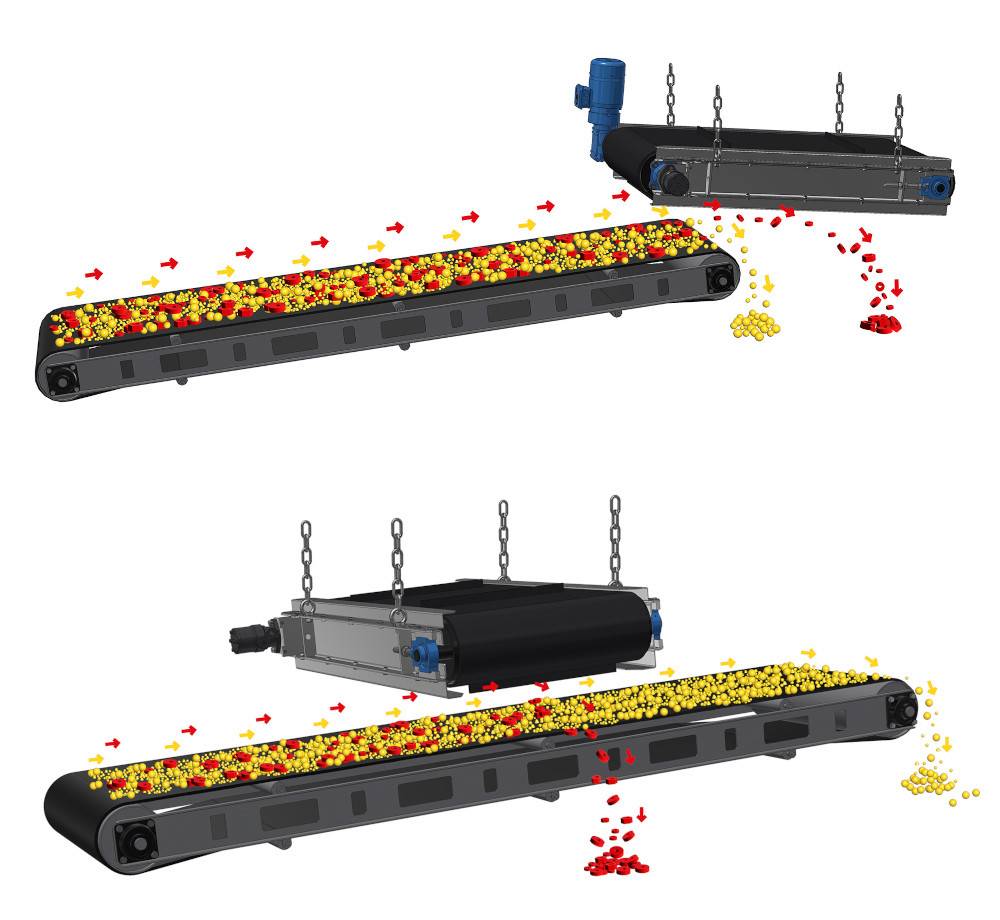

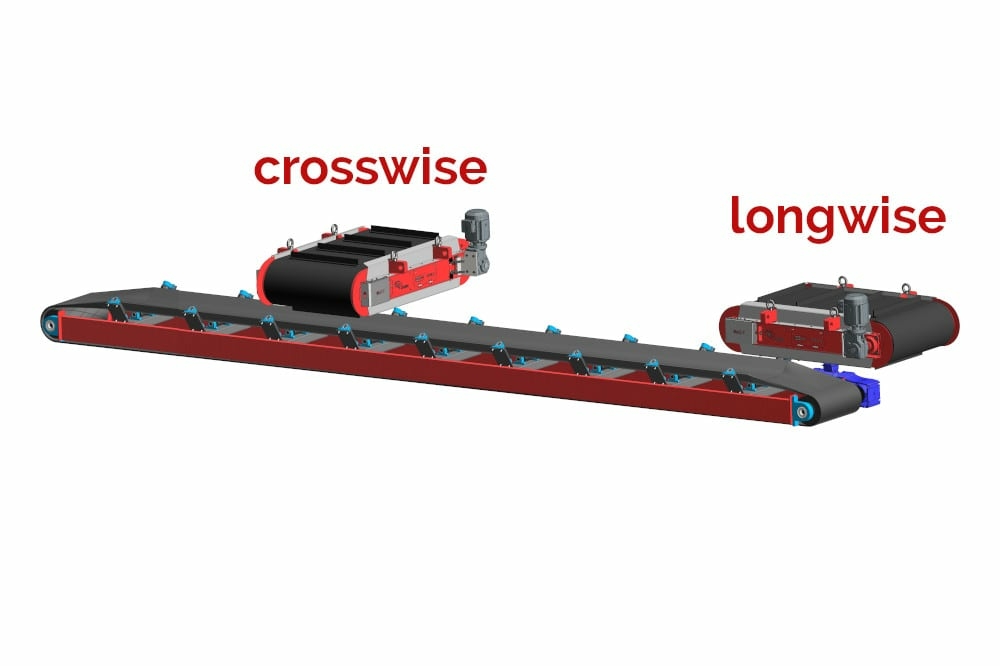

Installation of DND-AC overband magnets – transverse and longitudinal, based on operation type

Overband magnets are installed either transversely above the conveyor or longitudinally above the end roller – depending on the nature of the material and operating conditions.

For both installation methods, we offer specialized model series designed for maximum separation efficiency.

Installing longitudinally above the end roller is ideal for separating the material in its free fall when the mixture is more permeable. This method is suitable for materials with poor flowability or high bulk density when there is a thick material layer on the belt. Thanks to this, we can tailor a solution to each application!

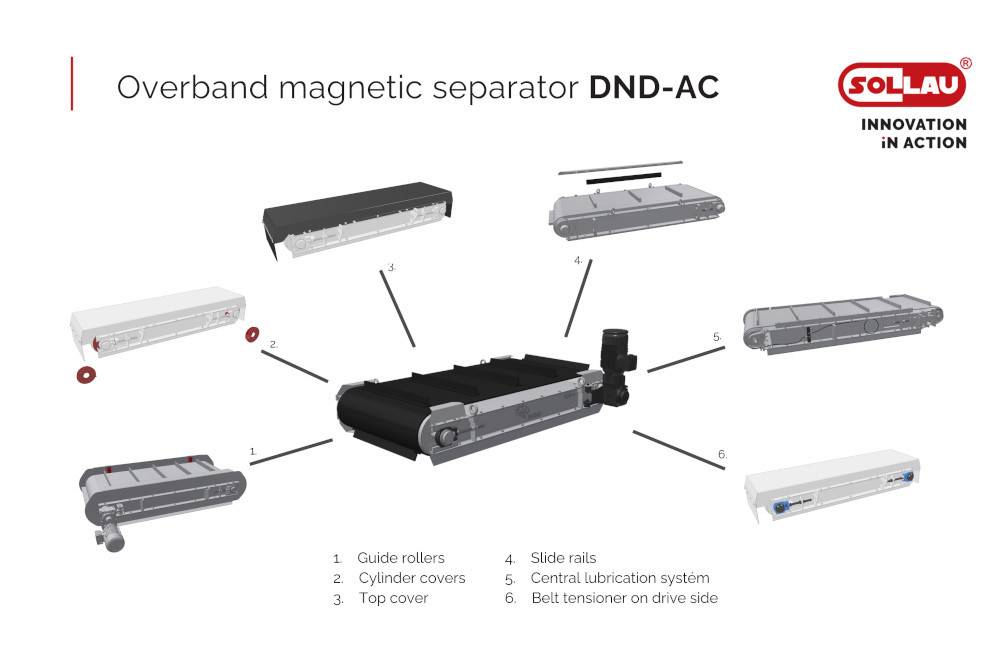

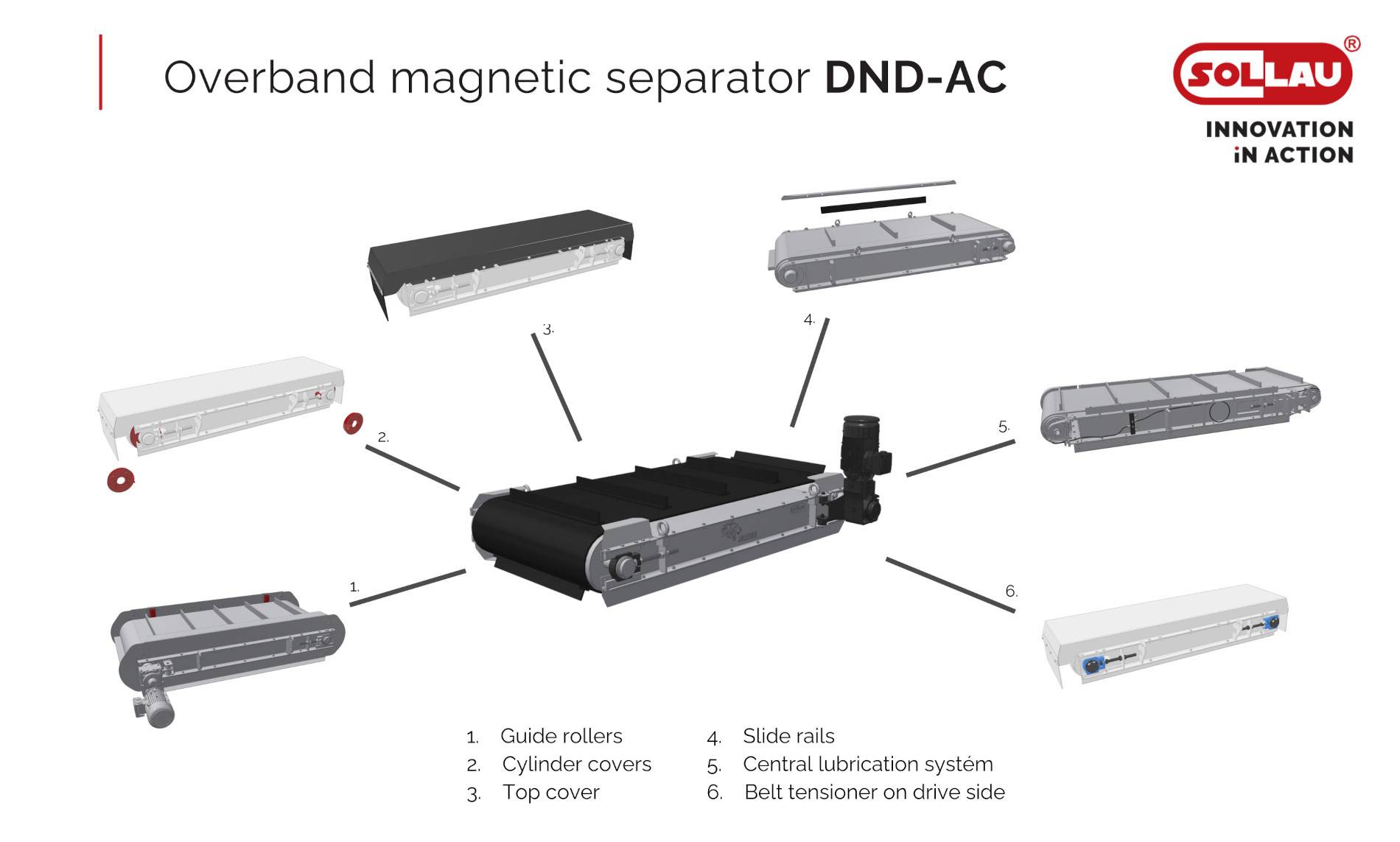

Wide range of optional equipment for DND-AC overband magnets

The DND-AC overband magnets can be easily adapted to the specific operational requirements using optional equipment. There are guide rollers, a central lubrication system, a top cover, sliding rails, roller covers, and belt tensioning on the drive side.

These additional solutions increase reliability, extend equipment life, and facilitate maintenance.

Thanks to the modular solution, the configuration can be set up exactly as required. The equipment is designed for both standard and demanding applications.

Looking for an affordable overband magnet?

The DND-AC ECO overband magnet is an affordable solution for separating ferromagnetic contaminants from heights up to 240 mm. It offers reliable performance, light weight, and compact dimensions. The steel sidewalls and open core design significantly reduce costs. The ECO range offers 7 standard sizes for conveyors from 500 to 1,800 mm wide, including hydraulic drive and motor orientation options. The ideal choice for operations where the price/performance ratio is decisive.

We measure the performance of overband magnets - no assumptions!

Verified results for each DND-AC model

We know that reliable separation of metal contaminants is not a given. That is why we treat every DND-AC overband magnet as an expert - each piece is carefully tested and the results documented.

These methods ensure that your device actually works as it should. A report with detailed measured values is provided with every delivered separator.

Look at the specific results for each model!

How does the cooperation work?

1.

We’ll arrive

2.

We’ll measure and design

3.

We’ll make to measure

4.

We’ll install

5.

We’ll put into operation and train

6.

We’ll provide authorized service

Case studies on the use of a DND-AC overband magnet

Efficient removal of ferrous contaminants from slag and foundry sand in the Holcim Magyarország Kft cement plant (case study)

JACKAL is in action! Strong, lightweight and immediately available! (case study)

Separation of metals from Solid Recovered Fuels (SRF) - the most powerful separator on a special price! (case study)

Separation of tramp iron from woodchips

Photo gallery from projects

Videos from projects

Technical documentation to download

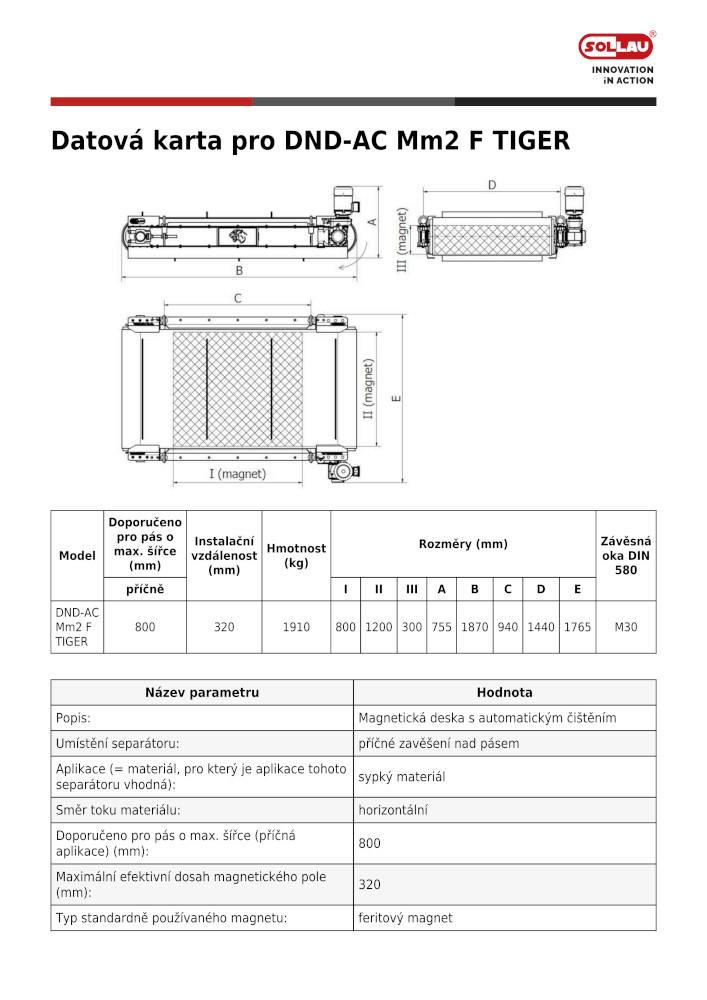

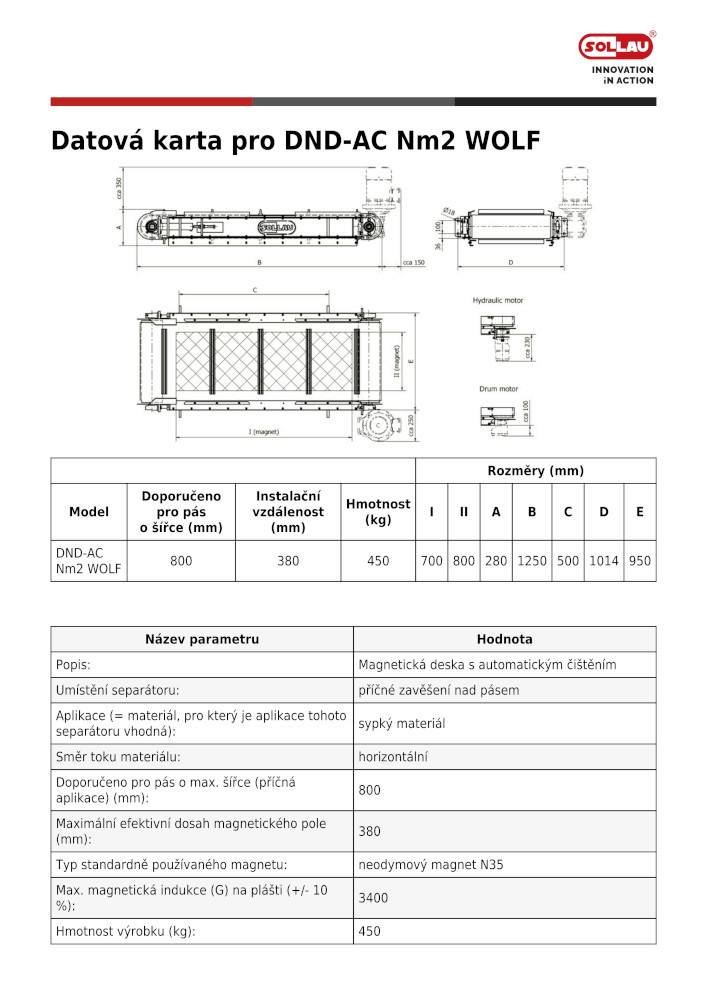

In the data cards, you will find all relevant technical information, incl. a drawing with dimensions.

We produce 12 different model ranges, each offering several sizes. Therefore, you will find almost 80 variations of overband magnets in our portfolio. For this reason, the data cards for each model are available on a separate page:

Most common FAQs – Overband magnet

The DND-AC overband magnets are used for the automatic separation of ferromagnetic contaminants (e.g., screws, nuts, wires) from dry materials conveyed by conveyor belts in most industries such as mining, recycling, energy, construction, and wood processing.

We offer 12 product lines that differ in magnet type (ferrite or neodymium), installation orientation (transverse or longitudinal), and performance. For more budget-conscious operations, the budget-friendly DND-AC ECO series is also available. Ferrite overband magnets have a deeper field range; in contrast, neodymium plates have extreme strength at a lower weight.

We test each separator by measuring the magnetic induction at real distances (0 - 400 mm) to see what types of contaminants it can capture (e.g., nuts, nails, balls). You find the results in the test reports that we publish transparently on the web.

The ferrite variants are installed up to a height of 500 mm. The neodymium variants are embedded up to 380 mm, and the economical ECO series up to 240 mm. The overband magnets can be installed transversely over the belt or longitudinally over the end roller, depending on the material type and operating conditions.

Yes, thanks to the modular system, the equipment allows for retrofitting with a range of accessories such as guide rollers, slide rails, top cover, central lubrication, or roller covers. This allows customization to the specific operational requirements and ensures higher operating life and reliability.

Standard delivery time starts at 5 weeks. We provide a 10-year warranty and guarantee service intervention within 2 working days.

Additional equipment for DND-AC

Download PDF

(size 1.09 MB)

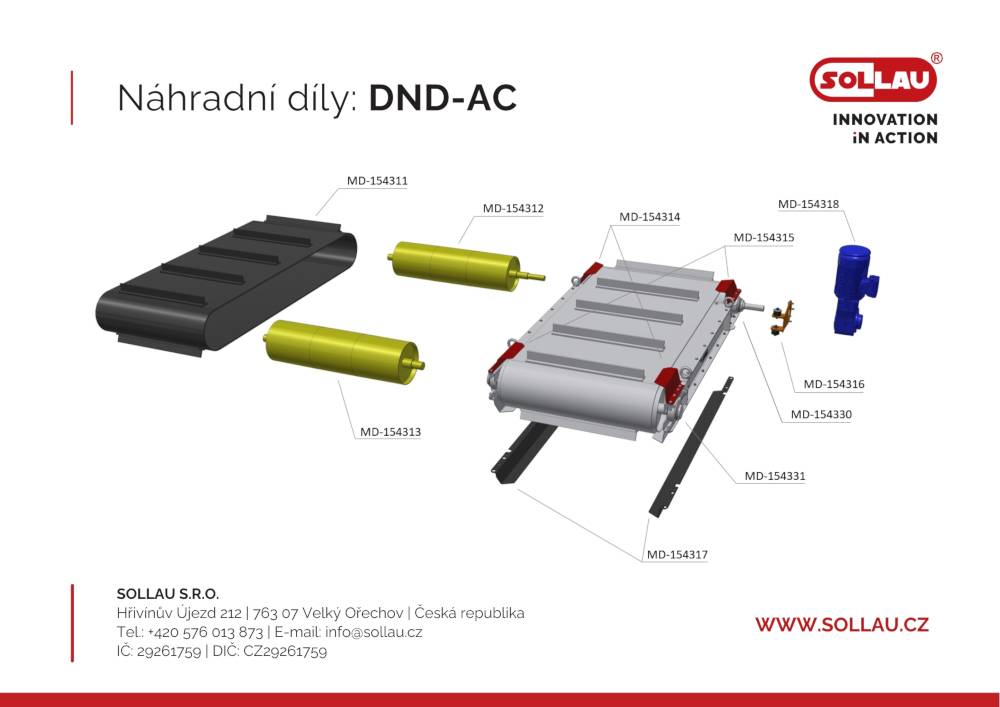

Spare parts for DND-AC

Download PDF

(size 254 kB)

Why choose SOLLAU overband magnets?

Download PDF

(size 768 kB)

Comparison of DND-AC overband magnet models

Download PDF

(size 642 kB)

Do you have a question?

Are you interested in the possibilities of using a magnetic separator?

Do you want to discuss modifications, customizations, or pricing?

Write to us, and we will get back to you within 24 hours.