Magnetic Separator for Industrial Magnetic Separation

SOLLAU is a European manufacturer and technology leader in magnetic separation, with decades of experience in designing high-performance magnetic separators for demanding industrial applications.

Our solutions are engineered to remove ferrous contamination reliably, protect critical process equipment and ensure consistent product purity – even in continuous, high-capacity operations where separation efficiency is critical.

Quick navigation

WHAT IS A MAGNETIC SEPARATOR?

A magnetic separator is a device designed to remove ferrous and magnetic metal contaminants from material streams using a magnetic field.

Magnetic separators are used for processing:

- bulk and powdered materials

- liquids and slurries

- materials conveyed on belts or in chutes

They are an essential part of magnetic separation, whose purpose is to eliminate metal contamination before it causes equipment damage, product contamination or safety risks.

Common industry terms include:

- magnetic separation

- metal contamination removal

- ferrous contamination separation

HOW MAGNETIC SEPARATION WORKS

Magnetic separation is a physical separation process in which magnetic forces actively attract ferrous metal particles from a flowing material.

Depending on the application, magnetic separation uses:

- permanent magnets (neodymium or ferrite)

- electromagnets for extremely high field strengths

High-performance magnetic separators are capable of capturing very fine ferrous particles down to approx. 1 micron, including wear particles generated by machinery or metal fragments introduced with raw materials.

Typical performance parameters of industrial magnetic separators include:

- magnetic field strength up to approximately 1.8 Tesla (18,000 Gauss), depending on separator design

- particle capture size down to approximately 1 micron

- operation in dry and liquid processes

- designs suitable for high temperatures, abrasive materials and ATEX environments

WHY MAGNETIC SEPARATION IS USED

Magnetic separation serves several critical purposes in industrial processing:

Protection of equipment

Magnetic separators protect crushers, mills, injection molding machines, conveyors and filling lines from damage caused by metal contaminants.

Material purity and product quality

Magnetic separation removes metal impurities from food, chemicals, plastic granules, ceramic powders and liquids.

Compliance with standards

Effective removal of metal contamination supports compliance with HACCP, IFS, BRC and ISO standards and helps pass customer and regulatory audits.

Economic efficiency

Reduced downtime, fewer breakdowns and lower reject rates result in fast return on investment, often within months.

SOLLAU magnetic separators use high-performance neodymium magnets to achieve maximum separation efficiency even for very fine contaminants.

TYPES OF MAGNETIC SEPARATORS (SOLLAU PORTFOLIO)

There is no universal magnetic separator. Each application requires a specific solution. SOLLAU designs magnetic separators tailored to operating conditions.

By design and application:

- Magnetic Grids: Multi-rod magnetic grids installed in hoppers and chutes, typically used as the first stage of magnetic separation to protect downstream equipment.

- Drum Magnetic Separators: Rotating magnetic drums designed for continuous magnetic separation of large material volumes.

- Plate Magnets: Flat magnetic separators installed above conveyors or inside material chutes.

- Overband Magnetic Separators: Suspended magnets mounted above conveyor belts for removal of tramp metal.

- Liquid Magnetic Separators: Flow-through magnetic separators designed for liquids, emulsions and slurries.

- Magnetic Rods: Simple yet powerful magnetic elements for bulk and liquid applications.

By cleaning method:

- Manual cleaning – metals removed by operator

- Automatic cleaning – continuous operation without operator intervention

By magnetic system:

- Permanent magnetic separators (neodymium or ferrite)

- Electromagnetic separators – extremely high magnetic field, switchable operation

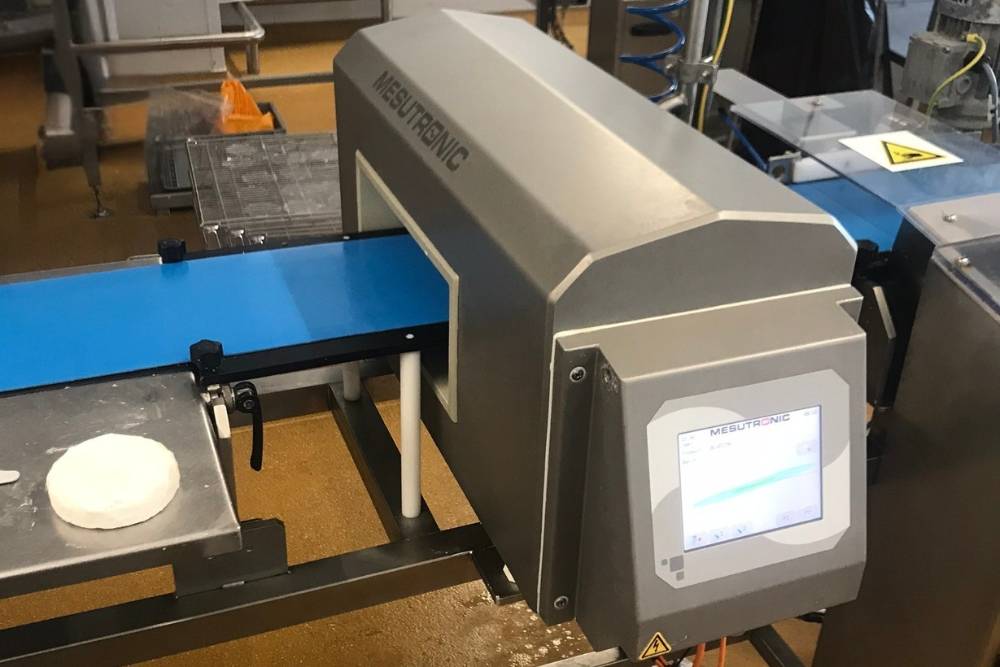

MAGNETIC SEPARATOR vs METAL DETECTOR

Magnetic separation and metal detection address the same risk – metal contamination – but in different ways.

MAGNETIC SEPARATOR

- Removes metal contaminants

- Protects processing equipment

- Operates continuously

METAL DETECTOR

- Detects metal contaminants

- Protects consumers

- Inspects final products

For maximum process safety, magnetic separation is often combined with metal detectors.

INDUSTRIES & APPLICATIONS

SOLLAU magnetic separators are used across a wide range of industries:

Food processing

Food processing

Flour, sugar, spices, dairy powders, chocolate, beverages

Plastics & rubber

Plastics & rubber

Granulate and regrind protection before molding or extrusion

Chemical industry & coatings

Chemical industry & coatings

Ochrana procesních zařízení při výrobě pigmentů, barev a chemikálií.

Recycling & waste processing

Recycling & waste processing

Plastics, glass, municipal waste, metal recovery

Mining & aggregates

Mining & aggregates

Protection of crushers and screens

Cement, lime & ceramics

Cement, lime & ceramics

Limestone, clay, porcelain materials

Wood processing

Wood processing

Sawdust, chips, MDF.

Pharmaceutical & cosmetics

Pharmaceutical & cosmetics

High-purity materials

Engineering & metalworking

Engineering & metalworking

Protection from metal swarf

And more.

WHY CHOOSE SOLLAU MAGNETIC SEPARATORS

IN-HOUSE DESIGN AND MANUFACTURING

EXTREMELY POWERFUL MAGNETIC SYSTEMS

CUSTOM-ENGINEERED SOLUTIONS

LONG-TERM OPERATIONAL STABILITY

REFERENCES WORLDWIDE

FAQ - MAGNETIC SEPARATOR & MAGNETIC SEPARATION

In most production lines, magnetic separation is installed upstream to remove ferrous contaminants and protect equipment, while metal detectors are used downstream for final product inspection.

Typical mistakes include incorrect separator positioning, insufficient magnetic field strength and choosing manual cleaning for high-contamination applications.

The correct magnetic separator depends on the material type, flow rate, transport method and size of metal contamination. SOLLAU designs separators individually for each application.

Magnetic separation removes ferrous metals and magnetic stainless steels. Non-magnetic metals require metal detectors or eddy current separators.

High-performance SOLLAU magnetic separators can capture particles from approximately 1 micron, including invisible wear particles.

Yes. SOLLAU magnetic separators are designed in accordance with HACCP, IFS and BRC standards and manufactured from food-grade stainless steel.

Cleaning frequency depends on contamination levels. For continuous processes, automatic cleaning magnetic separators are recommended.

Yes. Liquid magnetic separators are designed for oils, emulsions and slurries without restricting flow.

In most installations, ROI is very fast, often within months, due to reduced downtime, fewer breakdowns and lower reject rates.

Yes. SOLLAU specializes in custom magnetic separation solutions, including high temperatures, abrasive materials and ATEX environments.

CONTACT

MAGNETIC SEPARATION SOLUTION TAILORED TO YOUR PROCESS

Looking for a magnetic separator or a complete magnetic separation solution? Our specialists will design the optimal system based on your process parameters.

Are you interested in the possibilities of using a magnetic separator?

Do you want to discuss modifications, customizations, or pricing?

Write to us, and we will get back to you within 24 hours.