Spread feeder

Professional solutions for screening and separation in every industry.

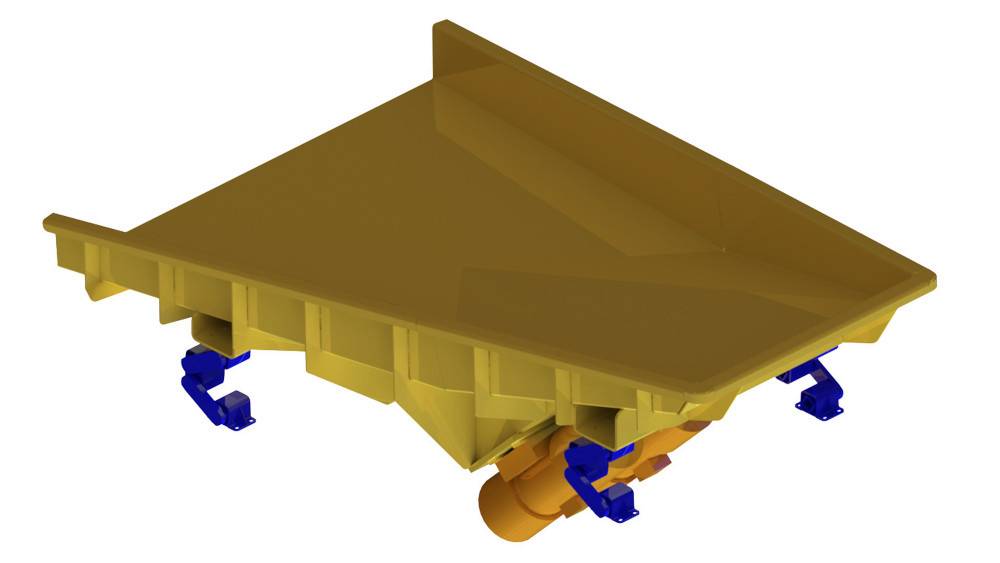

The spread feeder is a complex feeding device designed for installation beneath containers, where it ensures even and smooth spreading of bulk materials across the entire width of consequential technologies. This significantly increases the operational efficiency and flexibility of the entire process.

INDUSTRY: Mineral raw materials, Fasteners, Recycling

- Three drive types - with either fixed or continuously variable control of feed rate

- Variable design - open, closed, or dust-tight variation

- Capacity up to 400 m³/h

- Wide customization options.

Comprehensive solutions from SOLLAU - magnetic separators, metal detectors, vibrating sieves, and vibrating feeders - all in one place!

Need help choosing? We will be happy to recommend a solution tailored to your operation.

KEY FEATURES AND ADVANTAGES OF THE SPREAD FEEDER

- Three drive types - with fixed or continuously adjustable feed rate control for precise process control.

- Variable design - open, closed, or dust-tight option to meet stringent environmental requirements.

- Capacity up to 400 m³/h - suitable for smaller plants as well as for high-capacity lines.

- Even spreading - across the entire device width without material accumulation or clogging.

- Low operating costs - robust construction, minimal wear, and easy maintenance.

- Tailored solution - optional inserts, weighing systems, closing gates, sensors, and automation.

WHERE IS THE SPREAD FEEDER USED?

Vibratory spread feeders are used in a wide range of industry branches:

- quarrying of aggregates, sand, and gravel,

- cement works and the production of building materials,

- glass and ceramic industry,

- coal operations and power stations,

- production of metallurgical material,

- automotive industry,

- production of fasteners and technical components.

Customization options

The device can be equipped with optional elements, such as exchangeable inserts, regulatory gates, weighing systems, intelligent control units and advanced sensors. All this is for maximum customization to specific operating conditions.

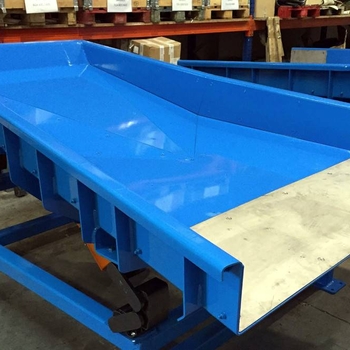

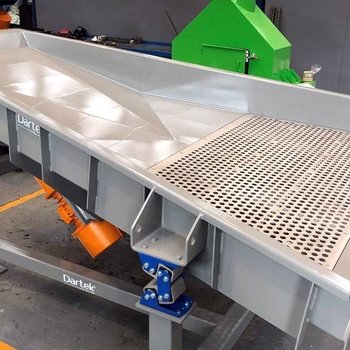

Photo gallery

Need help choosing? We will be happy to recommend a solution tailored to your operation.

Other vibrating feeders

The most common FAQ - Spread Feeder

The spread feeder is designed for bulk materials of different fractions - from fine granulate to coarser aggregates - in branches such as mining, recycling, building industry, or fastener production.

The equipment reaches a capacity of up to 400 m³/h, making it suitable even for high-capacity operations.

Yes. There are three types of drives available - with fixed or continuously adjustable speed control, ensuring precise dosing at the desired width.

Yes. The design is available in open, closed, and dust-tight versions, meeting strict hygienic or ecological requirements.

It can be equipped with, e.g., exchangeable inserts, weighing systems, control gates, automatic control, and sensors according to the specific needs of the operation.

They are used in aggregate mining, cement plants, glassworks, metallurgical and automotive industries, as well as in the production of fasteners.

How does cooperation work?

1.We will come

2.We will measure and design

3.We will manufacture to measure

4.We will install

5.We will commission and train

6.We will provide authorized service

Have a question?

Are you interested in using SKAKO vibratory feeders?

Would you like to discuss modifications, customizations, or pricing?

Write to us and we will get back to you within 24 hours.