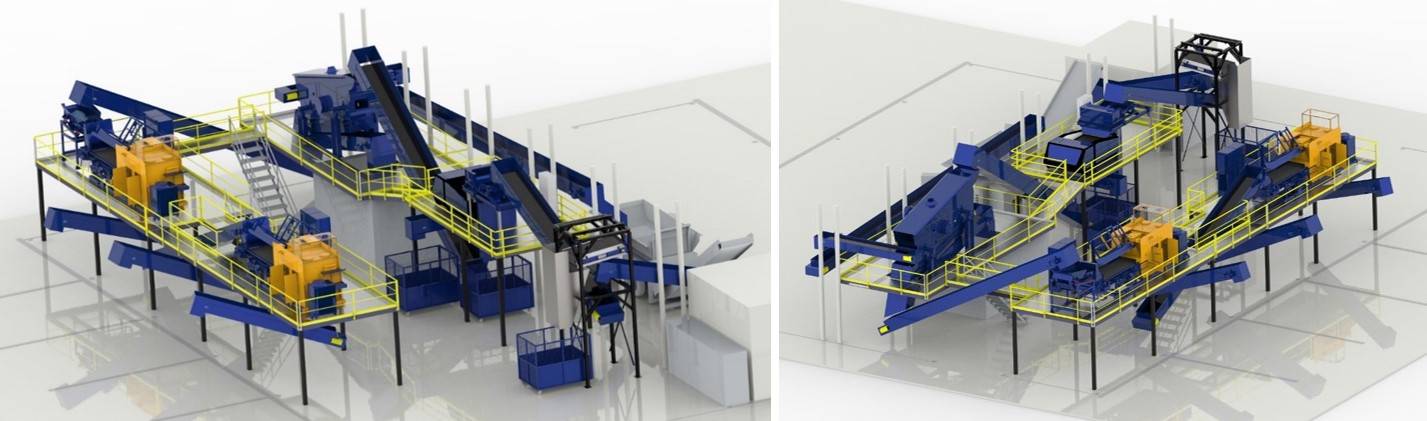

Automated sorting line for aluminum wheel discs

This automatic sorting line is designed for the separation of iron and aluminum car wheel discs. Its processing capacity is 9 t/h.

The aluminum and steel car wheel discs are transported to a crusher where they are crushed to a size of 50 x 50 mm.

Metal separation is performed in three stages:

- Stage 1 - primary separation of iron tramp using the DND-AC Ms8 F JAGUAR overband magnet. In this stage, most of the ferromagnetic objects are separated. The ferrous metals are automatically removed from the conveyor by the overband magnet.

- Stage 2- final separation of ferrous metals. To ensure highest quality of magnetic separation, we use a magnetic drum equipped with the strongest neodymium magnets. The magnetic drum with a diam. of 406 mm and a length of 1,000 mm is ideal for the separation of even the finest ferrous particles.

- Stage 3 - separation of non-magnetic metals. To remove non-magnetic metals (aluminum) from inert materials the ECS - E 1000 BULL eddy current separator with an eccentric rare earth rotor is used.

A vibrating feeder is placed in front of the non-ferrous metal separator so that the processed material is perfectly loosened and the eddy current separator can effectively separate the non-ferrous metals.

The separation line capacity

9 tons/hour

Output

The treated waste is sorted into two fractions of 50 x 50 mm:

- Aluminum

- Ferromagnetic metals

The sorting line consists of the following equipment:

- Conveying systems

- Crusher

- DND-AC Ms8 F - JAGUAR overband magnet

- MBZ 406 N 1000 GRIZZLY magnetic drum in housing

- Vibrating feeder

- Non-ferrous metal separator - the ECS-C 1000 BULL eddy current separator with an eccentric rare earth rotor - for conveyor belts of 1,000 mm width

- Metal detector

- Steel construction