Magnetic grate separators in housing MRZ

The liquid magnetic separator MRZ is designed to separate magnetic iron contamination from liquid substances (such as coolants and emulsions for various machining operations).

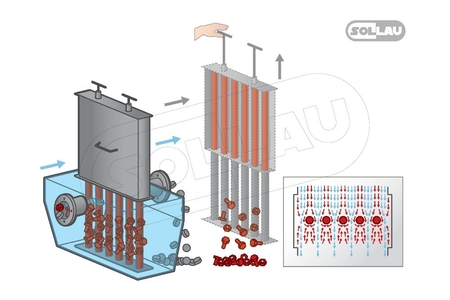

Design of the magnetic grate for liquids

The basic elements the magnetic grate separator in housing consists of are magnetic tubes (made from stainless steel). While the liquid material flows aroung the magnetic tubes, a very strong magnetic field (generated by the neodymium NdFeB magnets inside of the tubes) traps all metallic particles on the surface of the tubes. The sets of tubes are placed one above the other inside of the housing (or one behind the other – in case of a vertical position of the tubes) and the first set of tubes consists of one tube less. The grate sieve - created in this way – is in a very intensive contact with the flowing materia, can capture even the smallest ferromagnetic impurities and guarantees an extremely high separation efficiency. For best results the inlet part of the separator can be equipped with dispersion cones that disperse the material flow over the magnetic tubes.

Which way is the magnetic grid for liquid products cleaned?

The metal particles captured on the magnetic tubes migrate to the rear of the tubes where they remain protected from wash-off until the tubes are cleaned. During the cleaning the magnetic cores are pulled out of the tubes (either manually or pneumatically) into the upper part of the separator housing. The captured magnetic impurities fall off spontaneously. Thanks to the encased version of the magnetic grate separator the neodymium cores are totally maintenance-free.

If you use our magnetic grate separator in housing, you will improve the quality of your final products, you will be able to use the coolants in a repeated way and in particular we will help to protect your expensive machinery. The dimensions as well as the design of the magnetic grate separator in housing can be adjusted to client's needs.

SOLLAU – our products are welded by real professionals!

SOLLAU certifications:

Authorization to perform welding on pressure equipment according to PED 2014 / 68 / EU

Pressure welder certificate according to EN-ISO 3834 - 2, EN 1090 - 2, EN 13480 - 1 to 5, EN 13445 - 1 to 5

- High pull strength (up to 176 N)

- Upon request available also with pneumatic cleaning

- Heavy-duty stainless steel design

- Ideal for open flow systems

Is designed to separate magnetic iron contamination from liquid substances (such as coolants and emulsions for various machining operations).

| Product | Width (mm) | Height (mm) | Datasheet |

|---|---|---|---|

| MRZ 100 / 2 N | 100 | 100 | display PDF |

| MRZ 150 / 3 N | 150 | 100 | display PDF |

| MRZ 200 / 4 N | 200 | 200 | display PDF |

| MRZ 250 / 4 N | 250 | 200 | display PDF |

| MRZ 300 / 4 N | 200 | 300 | display PDF |

| MRZ 350 / 5 N | 350 | 300 | display PDF |

| MRZ 400 / 5 N | 400 | 400 | display PDF |

| MRZ 450 / 5 N | 450 | 400 | display PDF |

We produce magnetic separators in these three levels of magnetic induction

Which industrial branches can the grid magnet be used in?

The grate magnet in housing finds use especially in engineering.