Sorting line for recycling of cullet

Compound of the line

Case study

Principal types of challenges

- demanding application due to high level of abrasion of the material being processed (cullet)

- big quantity being processed (up to 10 tons/hour)

- necessity to separate both magnetic and also non-magnetic metal adulterants in a relatively small fraction (35 mm maximum).

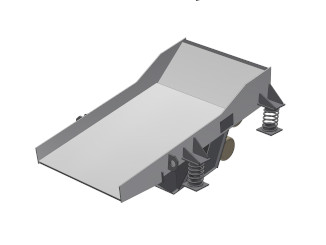

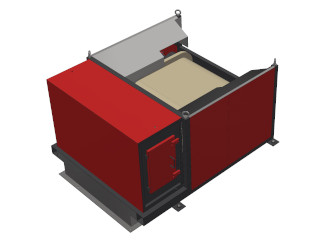

Solution provided by SOLLAU s.r.o. company: a coherent system of separators in an antiabrasive design (vibrating feeder reinforced with abrasion-resistant sheet metal of Hardox type, fully stainless MBZ 406 N 800 magnetic drum, ECS-C 800 separator for non-ferrous metals with a thickened conveyor belt) has been delivered. The line made by our company has not only managed a demanding task in an excellent way but also the ratio ´price/performance´ is highly appraciated by the client.

SOLLAU – our products are welded by real professionals!

SOLLAU – our products are welded by real professionals!