Magnetic grates MR with telescopic cores

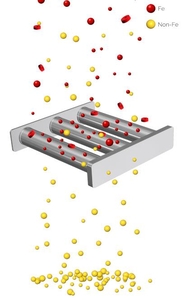

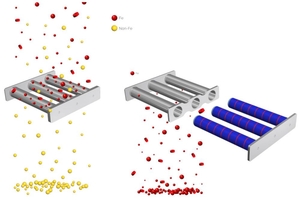

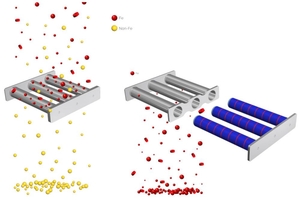

A magnetic grate is a simple separator designed to separate ferromagnetic particles from free-flowing dry materials. The basic elements the magnetic grate consists of are telescopic magnetic tubes (made from stainless steel). While the bulk powder material falls through the magnetic tubes, a very strong magnetic field (generated by the neodymium NdFeB magnets inside of the tubes) traps all metallic particles on the surface of the grids.

The magnetic grate separator is fitted with very strong neo magnets and can capture even not fully magnetic fragments (e. g., magnetic stainless steel). The dimensions as well as the design of the magnetic grid can be adjusted to client's needs.

How is magnetic grid cleaned?

We have several types of magnetic grids in our portfolio. They differ mainly in the way of cleaning and covering of magnetic cores:

-

Magnetic grid MR

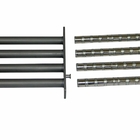

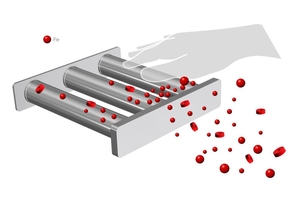

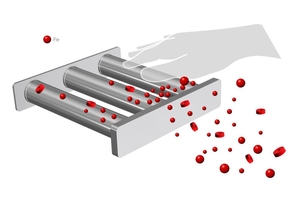

Magnets are inserted in a stainless steel housing. Cleaning is performed by sliding the magnetic cores out of the stainless steel housings. Ferromagnetic impurities trapped by the grid thus fall off easily. We produce the magnetic grid according to your dimensional requirements.

-

Magnetic grid MR-EKO

Magnets are placed fixedly Metals trapped by the magnetic grid must be removed from the grate manually. The advantage is the attractive price.

-

Magnetic grid MR-TT ("tube-in-tube" type)

In this type of magnetic grid the magnets are covered by a stainless steel tube which is tightly sealed. The magnets are thus protected from damage, which extends their lifetime. These covered magnets are embedded in a stainless steel housing. Cleaning is performed by pulling out the magnetic cores from the stainless steel housing, in the same way as at the MR type. The stainless steel tube protects the magnets during separation and the cleaning process.

Principle advantages of the grate magnets

This magnetic separator is very effective, maintenance-free, inexpensive to acquire and operate, easy to install and transport (from one application place to another), cheap and simply to clean and maintain.

Easy placing an order in e-shop

SOLLAU – our products are welded by real professionals!

SOLLAU certifications:

Authorization to perform welding on pressure equipment according to PED 2014 / 68 / EU

Pressure welder certificate according to EN-ISO 3834 - 2, EN 1090 - 2, EN 13480 - 1 to 5, EN 13445 - 1 to 5

- Quick and easy cleaning thanks to the system of telescopic magnetic tubes

- 18 700 Gauss on the magnetic core and up to 12200 Gauss on the stainless steel protective cover

- Large magnetic separation area (diameter of the magnetic tubes: 32 mm)

The magnetic grate is a simple separator designed to separate ferromagnetic particles from free-flowing dry materials.

| Product | Dimension (mm) | Datasheet |

|---|---|---|

| MR 200x200 N | 200 x 200 | display PDF |

| MR 250x200 N | 250 x 200 | display PDF |

| MR 300x300 N | 300 x 300 | display PDF |

| MR 350x300 N | 350 x 300 | display PDF |

| MR 400x400 N | 400 x 400 | display PDF |

| MR 450x400 N | 450 x 400 | display PDF |

| MR 500x500 N | 500 x 500 | display PDF |

| MR 550x500 N | 550 x 500 | display PDF |

We produce magnetic separators in these three levels of magnetic induction

- Budget version (attractive price/performance ratio)

- High pull strength

- Up to 13 000 Gauss on the stainless steel protective cover

- Only polished design

- Dense magnetic sieve

- Manual cleaning

- Diameter of the magnetic tubes: 25 mm

MR-EKO magnetic grate is an uniphase separator serving to catching ferromagnetic particles coming loose compounds. The magnetic grate is recessed with strong neodymium NdFeB magnets and it is able to catch even only the partially magnetic metal particles (e. g. weakly magnetic stainless steel). We are able to adjust the dimensions and global design to the customer´s requests.

| Product | Dimension (mm) | Datasheet |

|---|---|---|

| MR EKO 100x100 N | 100 x 100 | display PDF |

| MR EKO 150x150 N | 150 x 150 | display PDF |

| MR EKO 200x200 N | 200 x 200 | display PDF |

| MR EKO 250x250 N | 250 x 250 | display PDF |

| MR EKO 300x200 N | 300 x 200 | display PDF |

| MR EKO 300x300 N | 300 x 300 | display PDF |

| MR EKO 350x350 N | 350 x 350 | display PDF |

Some products from this model family are available for immediate purchase. We are constantly extending the offer of our magnetic separators in stock so that we can deliver them to you immediately. Please, contact our dealer to inform for their current availability.

- Budget version (attractive price/performance ratio)

- High pull strength

- 12 500 Gauss on the magnetic core and up to 10 000 Gauss on the stainless steel protective cover

- Only polished design

- Dense magnetic sieve

- Tube-in-tube system (double protection of the magnetic core)

- Quick and easy cleaning thanks to the system of telescopic magnetic tubes

- Diameter of the magnetic tubes: 25 mm

MR-TT magnetic grate is a simple separator serving to cjatching ferromagnetic particles coming from looese compounds. Identification TT means that it is a so called version „tubing in tubing“ (the magnetic cores are laid airproof in a stainless bushong and only after that put into the stainless grate).

Thos solution offers a few advantages: partly it porlongs the service life of expensive magnetic cores significantly (water cannot penetrate to them, mechanic abrasion of them does not occur when cleaned etc.), partly a risk of unstricking a piece of magnetu or its nickle-coating (and with this connected unwanted penetration into the material being cleaned) is eliminated and also resistance of the whole grate against abrasion is increased. A slight disadvantage is little lower magnetic induction on the surface of the grate, nevertheless this magnetic grate is bedded with the strongest existing neodymium magnets and it is able to catch also only partially magnetic metal particles (e. g. weakly magnetic stainless steel). The telescopic construction ensures easy and quick cleaning of the í magnetic grate. The metal impurities fall off spontaneously out of the stainless tubes by protuberance of permanent neo magnets.

| Product | Dimension (mm) | Datasheet |

|---|---|---|

| MR-TT 100x100 N | 100 x 100 | display PDF |

| MR-TT 150x150 N | 150 x 150 | display PDF |

| MR-TT 200x200 N | 200 x 200 | display PDF |

| MR-TT 250x250 N | 250 x 250 | display PDF |

| MR-TT 300x200 N | 300 x 200 | display PDF |

| MR-TT 300x300 N | 300 x 300 | display PDF |

| MR-TT 350x350 N | 350 x 350 | display PDF |

Some products from this model family are available for immediate purchase. We are constantly extending the offer of our magnetic separators in stock so that we can deliver them to you immediately. Please, contact our dealer to inform for their current availability.

Which industrial branches can the magnetic grid be used in?

The telescopic magnetic grates find use in recycling and mining as well as in wood, plastic, ceramic and glass industry.