Mobile Sorting Line – Technology Overview

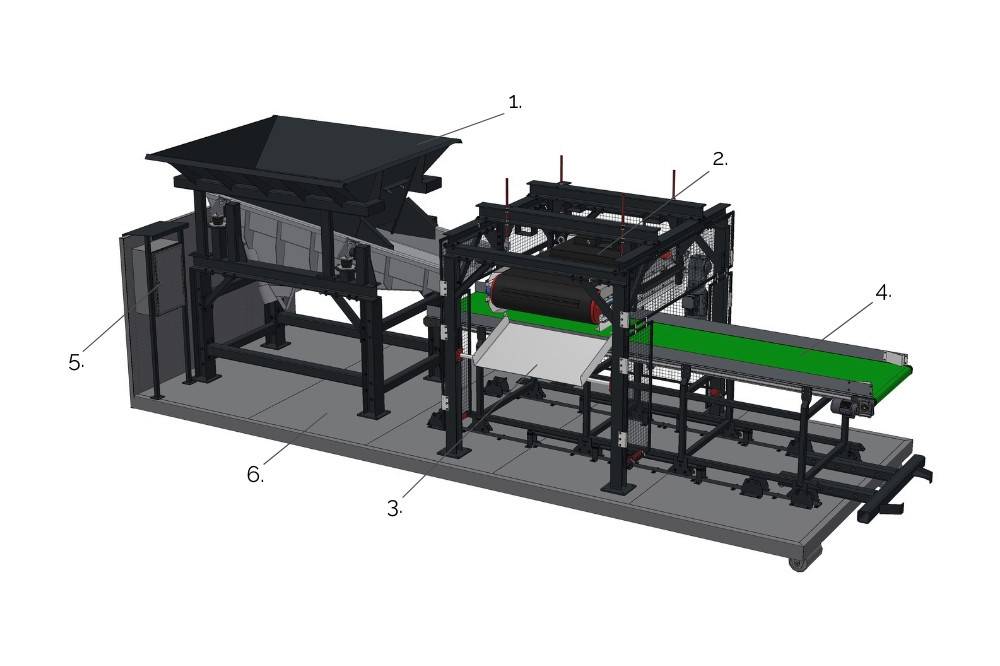

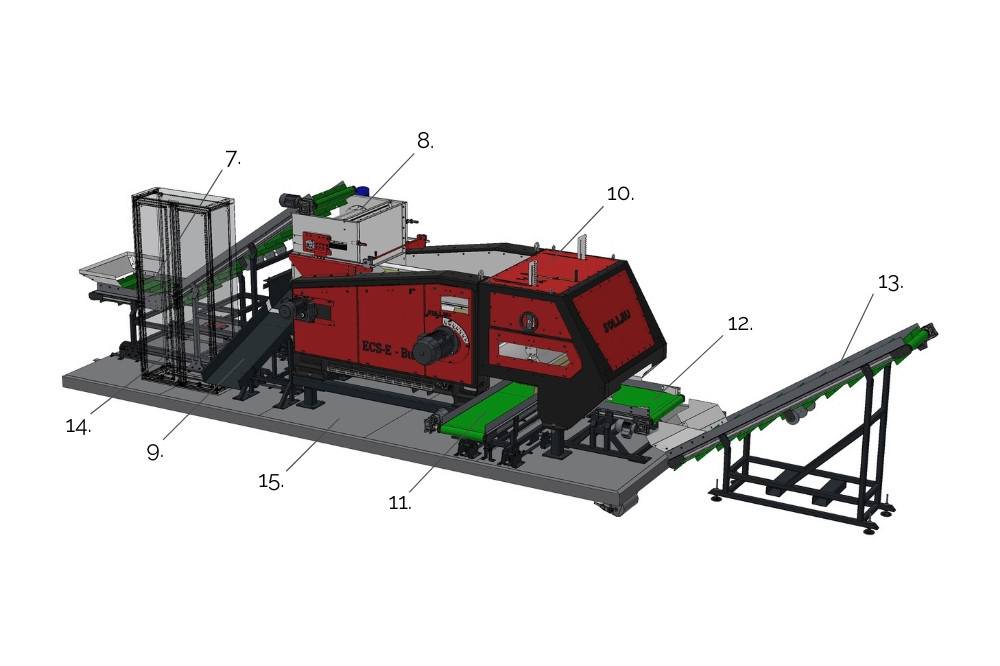

A mobile separation line for sorting magnetic and non-magnetic metals from inert material. It consists of two modules. Both modules are mounted on an Abroll platform, allowing the entire sorting line to be easily relocated.

The sorting line includes standard magnetic separators for removing ferrous impurities and an eddy current separator for separating non-magnetic metals from non-metallic materials.

The second part of the mobile sorting line is enclosed. Each part of the line can be used independently or together – depending on the separation purpose.

We will design the configuration of the mobile separation line and its individual components to suit the separation purpose and your needs!

The mobile sorting line consists of the following equipment

Module 1

- 1Vibratory feeder with hopper

- 2Self-cleaning magnetic plate DND-AC

- 3Chute – Fe contaminants

- 4Belt conveyor

- 5Control cabinet 1

- 6Abroll container 1

Module 2

- 7Angled belt conveyor

- 8Magnetic drum

- 9Chute – Fe contaminants

- 10ECS – E BULL

- 11Belt conveyor – inert material

- 12Belt conveyor – non-magnetic metals

- 13Discharge conveyor

- 14Control cabinet 2

- 15Abroll container 2

1 Vibratory feeder with hopper

- Vibratory trough – length 3000 mm, width 950 mm

- Hopper volume approx. 1.5 m3

- Hopper material – steel 11 373/11 523

- Surface finish – RAL painting as required

2 Self-cleaning magnetic plate DND-AC Ms2 F JAGUAR – magnetic separation, stage 1

- Automatic magnetic separator for removal of Fe particles

- 1st stage of magnetic separation – captures the main volume of ferromagnetic particles

- Ferrite magnets

- Suspension height 270 mm

- The DND-AC hanging frame is removable so that the separation line can operate without this magnetic separation stage

- Frame material – steel 11 373/11 523

- Frame surface finish – RAL painting as required

3 Chute – Fe contaminants

4 Belt conveyor

- Working belt width – 800 mm

- Conveyor length – 3500–4000 mm

- NORD drive 1.1 kW with frequency inverter

- Conveyor material – steel 11 373/11 523

- Conveyor surface finish – RAL painting as required

5 Control cabinet 1

- Control of the vibratory feeder + DND-AC + belt conveyor

- Standalone cabinet for Module 1 – can be interconnected with Control cabinet 2 (controlling Module 2) so the entire sorting line can be operated from Control cabinet 2

6 Abroll container 1

- Dimensions: 6500 × 2550 × 1470 mm.

- Hook 50 mm – steel 11523 – shape per DIN 30722.

- Hook height 1570 mm.

- Runners INP 180, spacing per DIN 30722 – reinforcement at runners per DIN 30722.

- Uprights INP 180.

7 Angled belt conveyor

- Working belt width – 800 mm

- Conveyor length – 3600 mm

- NORD drive 1.1 kW with frequency inverter

- Conveyor material – steel 11 373/11 523

- Conveyor surface finish – RAL painting as required

8 Magnetic drum MBZ 304 N 800 GRIZZLY – magnetic separation, stage 2

- Automatic magnetic separator for removal of Fe particles

- 2nd stage of magnetic separation – to ensure perfect separation of Fe particles

- Very strong neodymium NdFeB magnets

- Drum diameter 204 mm, drum length 800 mm

- Drum housing – stainless steel 1.4301

- Adjustable magnetic drum position

- Frame material – steel 11 373/11 523

- Frame surface finish – RAL painting as required

9 Chute – Fe contaminants

- Equipped with a vibratory drive

10 Eddy current separator ECS–E 800 BULL 12 – separation of non-magnetic metals

- Eddy current–based separator – separates non-magnetic metals (aluminium, copper, brass) from inert material (wood, plastic, paper,…)

- Eddy current separator with eccentrically mounted rotor

- Separation of particles from 1 mm

- Belt width 800 mm

- Stepless rotor position adjustment during operation

11 Belt conveyor – inert material

- Removal of separated inert material – wood, paper, plastic, glass,…

- Conveyor mounted on rails – easy pulling out and pushing in of the conveyor (for transport)

12 Belt conveyor – non-magnetic metals

- Removal of separated non-magnetic metals – aluminium, copper, brass,…

- Conveyor mounted on rails – easy pulling out and pushing in of the conveyor (for transport)

13 Inclined conveyor – non-magnetic metals

- Discharging separated non-magnetic metals into a container

- Working belt width – 500 mm

- NORD drive 1.1 kW with frequency inverter

- Conveyor material – steel 11 373/11 523

- Conveyor surface finish – RAL painting as required

14 Control cabinet 2

- Control of magnetic drum + ECS-E + conveyors

- Standalone cabinet for Module 2 – can be interconnected with Control cabinet 1 (controlling Module 1) so the entire sorting line can be operated from Control cabinet 2

15 Abroll container 2 – with enclosure

- Abroll container base up to 12 t, two sliding side tarpaulins, rear tarpaulin, fixed roof

- Dimensions: 6500 × 2470 × 2484 mm.

- Roof – fixed sheet metal roof, thickness 1.5 mm

- Sides – sliding tarpaulin tensioned with straps, flip-over rear tarpaulin

- Hook 60 mm – steel 11523 – shape per DIN 30722.

- Hook height 1570 mm.