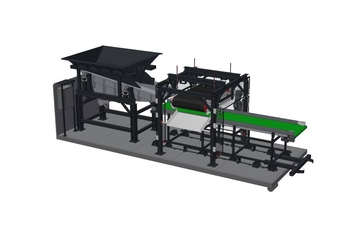

Mobile sorting line

The SOLLAU mobile sorting line = a solution for sorting magnetic and non-magnetic metals directly at the place of processing. Thanks to its mobility and fully customizable configuration, it significantly reduces handling costs and increases separation efficiency.

- Fully mobile sorting line – fast relocation and efficient metal sorting right at the source.

- Comprehensive metal separation – two-stage magnetic separation + eddy current technology for maximum fraction purity

- Modular separation system – independent or combined operation of both modules for higher metal-sorting efficiency.

- Customer-specific solution – line composition, performance, enclosure and conveying routes tailored to your separation needs.

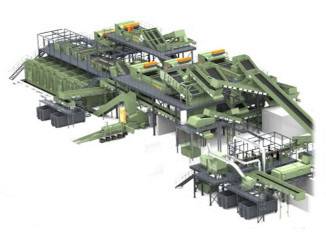

The mobile sorting line is a compact solution for efficient sorting of magnetic and non-magnetic metals from inert material (wood, plastic, paper, glass, …) directly at the processing site.

Advanced technologies ensure high fraction purity and speed up the entire separation process.

Modules on roll-off platforms enable rapid transfers between sites, reducing the need to transport material and allowing separation where it is most economical.

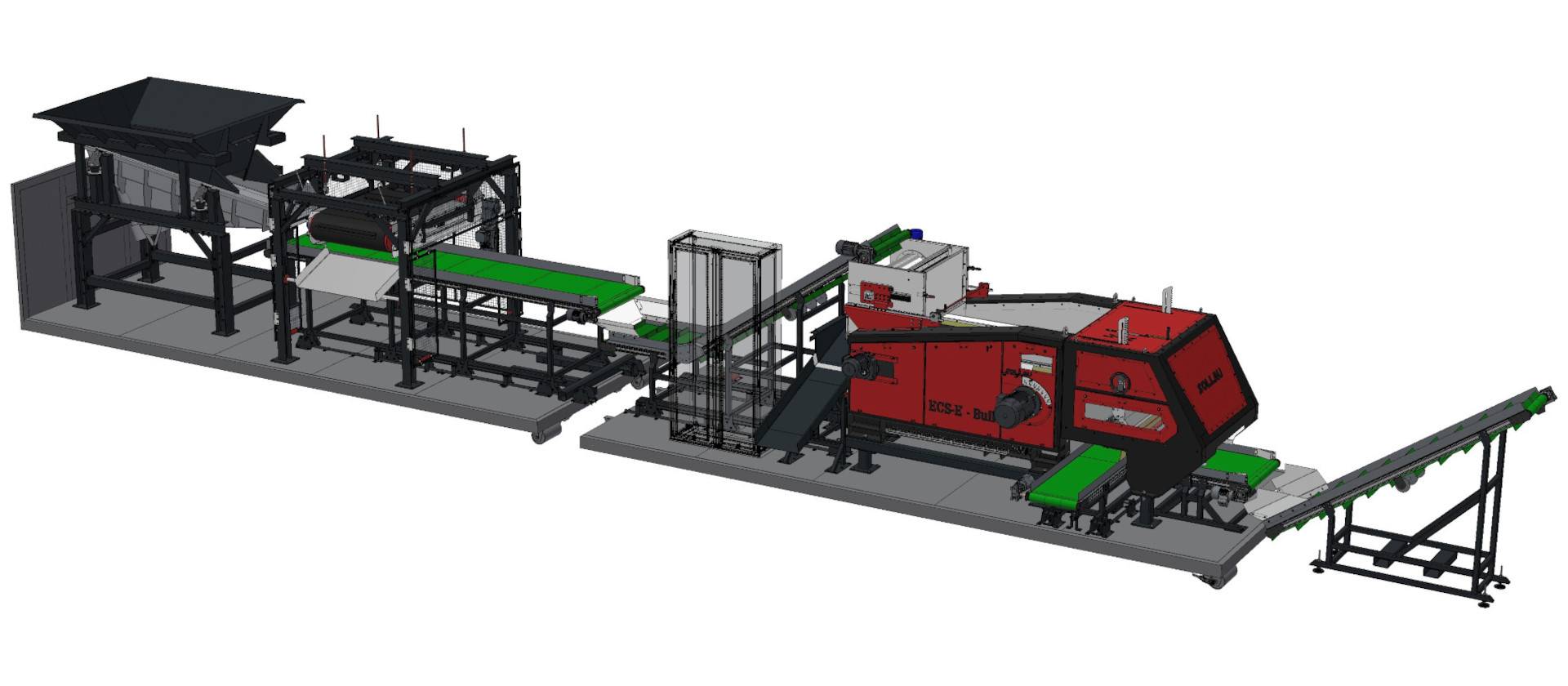

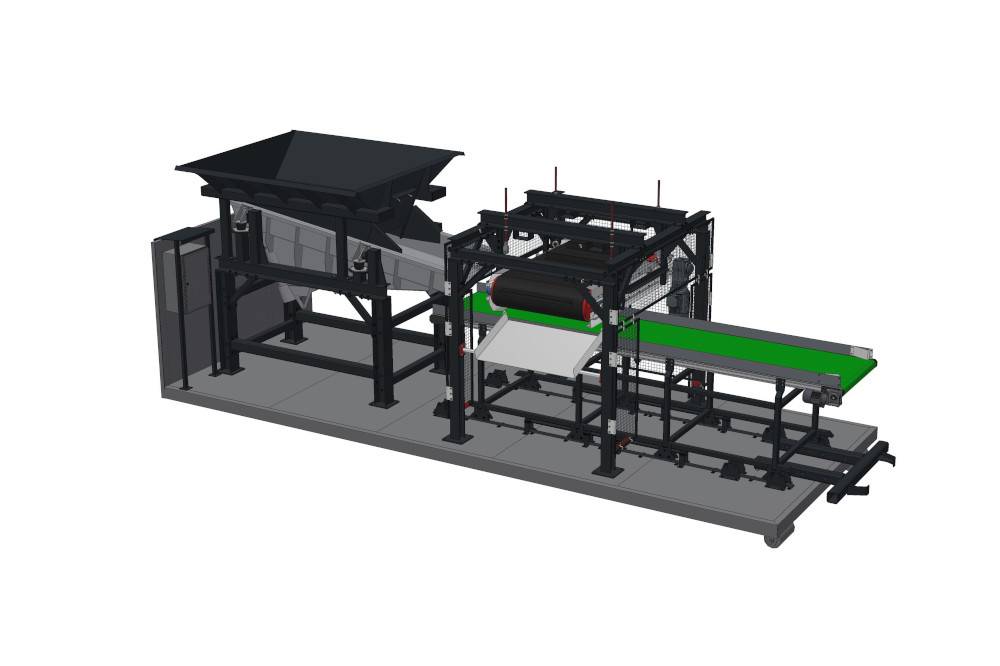

The first module handles material intake. Material is usually loaded with a grapple into the hopper, then moves to a vibrating feeder for even distribution. The self-cleaning magnetic plate DND-AC provides the first stage of ferrous separation, after which the material proceeds to the conveyor leading to module 2.

The second module is placed on an enclosed platform. The MBZ magnetic drum performs fine magnetic separation, while the ECS-E eddy current separator separates non-magnetic metals from inert materials.

Discharge fractions are handled by conveyors that are mounted on rails for easy pull-out and push-in, simplifying transport and maintenance.

The entire line can be customized to specific requirements — from the choice of separators to conveyor configuration.

Let the sorting technology travel to the material — not the material to the technology

Mobile sorting line – what is it made of?

Module 1

- Roll-off container

- Vibrating feeder with hopper

- Self-cleaning magnetic plate DND-AC – Fe separation

- Chute and conveyor

Module 2

- Roll-off container – enclosed

- Magnetic drum MBZ – Fe separation

- Eddy current separator ECS – Al separation

- Chutes and conveyors

How does cooperation work?

1.We will come

2.We will measure and design

3.We will manufacture to measure

4.We will install

5.We will commission and train

6.We will provide authorized service

3D model of the sorting line

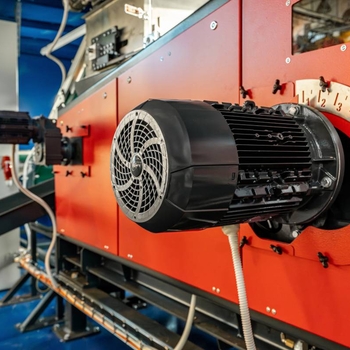

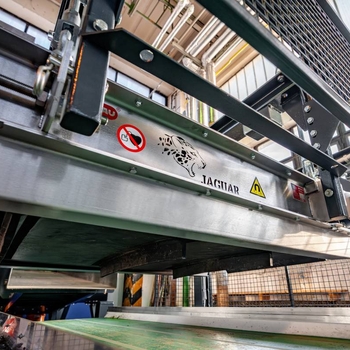

Photo gallery from installations

Frequently Asked Questions (FAQ) – Mobile sorting line

Minimal. Both modules are on roll-off platforms, so you simply load them onto a standard hook-lift truck and move them where sorting is needed. Installation requires no civil works — once positioned, just connect power, unfold the conveyors and the separation line is up and running within minutes. The result is maximum flexibility and significant savings in logistics costs.

The line is designed for operations where fast installation, mobility and efficient metal separation are crucial. Typical use includes:

- recycling yards,

- scrap yards,

- mobile waste processing within corporate groups,

- temporary metal-sorting sites (e.g. during refurbishments or seasonal projects),

Thanks to its modular design, the line can be used in parts independently or as a compact two-stage system.

Yes. The entire line can be configured according to the input material, required fractions and capacity. Possible modifications include the choice of magnetic separators, conveyor specifications, customized enclosure, performance parameters and integration into the existing material-handling system. SOLLAU provides tailor-made design so that the sorting line delivers maximum separation efficiency for the given application.

The biggest savings come from eliminating the need to transport material to a central sorting site. Thanks to cleaner metal fractions you get higher purchase prices and less material ends up as mixed waste. For operations working with metal waste daily, payback is often surprisingly fast — a matter of months, not years. The exact ROI can be calculated based on the amount of material you process.

Downloads

Module 1

Download PDF

(size 376 kB)

Module 2

Download PDF

(size 352 kB)

Do you have a question?

Are you interested in the possibilities of using the non-ferrous metal separator?

Do you want to discuss modifications, custom options or price?

Write to us and we will get back to you within 24 hours.