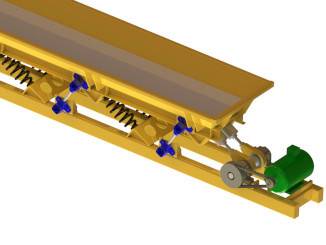

Storage Feeder & Hopper

The storage feeder & hopper combines the functions of a container and a feeder into one compact solution.

It is designed for uniform dosing and controlled flow of bulk materials from the container to downstream technologies.

Its construction eliminates the need for a separate storage bin and significantly increases the efficiency of the entire material handling process.

INDUSTRY: Connection accessories, Recycling

- Integrated bin and feeder - combining the bin and feeder into one device minimizes space requirements and technology acquisition costs.

- High capacity - load capacity up to 4,000 kg and volume of 2,240 liters.

- Material size - designed to handle bulk materials up to 220 mm without the clogging risk.

Comprehensive solutions from SOLLAU - magnetic separators, metal detectors, vibrating sieves, and vibrating feeders - all in one place!

Need help choosing? We will be happy to recommend a solution tailored to your operation.

KEY FEATURES AND ADVANTAGES OF A VIBRATING FEEDER & HOPPER

- Two functions in one - the clever combination of the bin and feeder in one solution reduces investment costs and space requirements.

- Controlled dosing - smooth and controlled material release ensures optimal flow without overloading downstream technology.

- Size - the storage feeder is designed to handle materials up to 220 mm in size

- High capacity - load capacity up to 4,000 kg and volume of 2,240 liters.

- Continuous feed control - Thanks to electromagnetic drives, the feed speed can be precisely adjusted to the current needs of the operation.

- Construction - open construction with a bin

- Tailored solution - optional inserts, weighing systems, closing gates, sensors, and automation.

WHERE ARE THE VIBRATING FEEDERS & HOPPERS USED?

They are used in a wide range of industry branches:

- Connection accessories,

- Quarrying and processing of aggregate, sand, and gravel,

- Glass production,

- Automotive industry.

Customization options

The device can be equipped with optional elements, such as exchangeable inserts, regulatory gates, weighing systems, intelligent control units and advanced sensors. All this is for maximum customization to specific operating conditions.

Photo gallery

Need help choosing? We will be happy to recommend a solution tailored to your operation.

Other vibrating feeder

The most common FAQ – Storage Feeder & Hopper

The storage feeder combines the functions of a bin and feeder in one device, saving space and costs.

The device has a load capacity of up to 4,000 kg and a volume of up to 2,240 liters, making it suitable for larger operations.

It is destined for bulk materials up to 220 mm without the risk of clogging or uneven flow.

Yes. Its compact design makes it suitable for stand-alone use as well as for integration into production lines.

This is achieved through electromagnetic drives that enable precise output adjustment based on current operational requirements.

Yes. They are: exchangeable inserts, weighing systems, closing gates, sensors, and automatic control.

How does cooperation work?

1.We will come

2.We will measure and design

3.We will manufacture to measure

4.We will install

5.We will commission and train

6.We will provide authorized service

Have a question?

Are you interested in using SKAKO vibratory feeders?

Would you like to discuss modifications, customizations, or pricing?

Write to us and we will get back to you within 24 hours.