Mobile crushing and sorting line

The mobile crushing and separation line is the ideal solution for the immediate processing of plastic waste in the production process.

The mobile crushing and separation line is the ideal solution for the immediate processing of plastic waste in the production process.

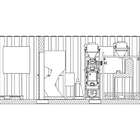

The entire technology is housed in a self-contained mobile container.

The entire technology is housed in a self-contained mobile container.

The mobile crushing and separation line contains

- Granulator

- Dust collector

- Magnetic separator

- Metal detector

The resulting plastic regrind is filled directly into big bags facilitating subsequent handling.

A detailed description of the individual devices used in the mobile sorting and crushing line can be found below in the “Detailed description” section.

As the manufacturer of this crushing and separating line we can adapt the equipment to your requirements.

How to lower unnecessary transport costs and the price of the final crushed material?

There is no need for demanding and expensive logistics such as the transport of the material for crushing outside the company premises and the subsequent return transport of the plastic regrind.

Simply put, on one side you load plastics to be crushed into the container, and you pick up a big bag with plastic regrind on the other side.

Let the crushing technology travel to the material, not the material to the technology = significant cost reduction!

This container can be placed directly in the plastics factory (indoors or outdoors) - depending on the customer's needs.

What is the mobile crushing and separation line composed of? This is the basic configuration - we can modify it according to your requirements!

Granulator – ZERMA GSE 300/600

- High-speed granulator - suitable for grinding various types of plastic materials

- Driving power: 11 kW

- Capacity: 150 - 750 kg / hour depending on the material type

- Rotor diameter: 300 mm

- Rotor width: 600 mm

Dust collector OZ 1200

- Capacity: 1,200 kg / h

- Minimum size of the particles that can be separated by the standard OZ 1200: 520 - 620 microns

Magnetic separator MSS-MC 150/5 N

- Multi-stage magnetic separation

- Capacity: 7 m3/h

- Magnetic induction: 18,700 G

Gravity metal detector UICKTRON 03 R 100

- Detector sensitivity - Fe ball diam.: 1,0 mm

- Capacity: 11,200 l / h

External dimensions of the mobile line

- Length: 606 cm

- Width: 244 cm

- Height: 259 cm

Heating, lighting and wiring system

This line is equipped with an electric heating unit, enabling temperature regulation inside the container. High-quality interior lighting in the workplace is a matter of course.

The mobile line includes complete wiring and an electric meter for accurate monitoring of power consumption.

Work safety

For safety reasons, the entire technology (the granulator, the dust collector, the magnetic separator and the metal detector) is separated by a folding door. Only the opening for feeding the material into the granulator is accessible.