Magnetic coolant separators MVS

A magnetic coolant filter serves to the continuous and automatic separation of ferromagnetic coming from cooling emulsions and oils.

Benefits of using the coolant recycling system

- Material free of ferromagnetic contaminants

- Permanent protection of the technological device

- Fluent manufacturing operation

- Prolongation of the service life of cutting fluids, cooling liquids and hydraulic liquids

- Prolongation of the service life of surfacing tools

- Reduction of abrasion of pumps and nozzles

- Reduction of maintainance costs

- Reduction of non-operating states

- Quality improvement of final products

- Elimination of problems with the removal of the hazardous waste in the form of paper and textile filters

Customer care

Your project will be taken care of by us from beginning up to the very end. It does not end with the order placed at us. We will provide the full support for all the time of the use of the separator.

1. We will come

2. We will align and design

3. We will make a made-to-measure product

4. We will install

5. We will put into operation and school in

6. We will provide authorized service

We guarantee tests withing three days!

Make sure that our device perfectly meets your expectations!

We will provide tests of your material on our magnetic separators for FREE!

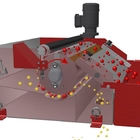

Staging separation cylinder serves to continuous and automatic separation of the ferromagnetic particles from cooling emulsions and oil at the machine tools. The staging separation cylinder is an unmanned appliance with a high level of separation. It is used for catching ferromagnetic particles coming from the liquids miscible by water, oil based emulsions with various content of mineral oil, synthetic cooling liquids etc.

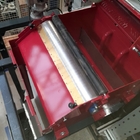

Construction of the separative vessel

There is a set of magnetic cores consisting of ferrite or neodym magnets positioned in the middle of a magnetic roller revolving on the spindle. The magnetic metal particles contained in the liquid are caught by the actuation of the magnetic field and are brought in towards the scraper that mops them mechanically into a collecting vessel. The clean-out liquid flows out under the roller to be processed further.

The process of separation can be monitored via an inspection window (MVS LUX design).

Which way does the separation vessel work?

Thanks to the quality of the materials used at the manufactuting of staging separation cylinder (stainless steel, set of permanent ferrite or neodym magnets) and a robust structure the staging separation cylinder is a reliable, maintainance-free, easily installable and operationally undemanding device with a long service life. During the application of the permanent ferrite magnets a nearly time-unlimited service life is guaranteed, nevertheless if a higher magnetic power or catching fine ferromagnetic particles are required, it is recommended to bed the roller with extremely strong neodym magnets coming from rare earths.

You will increase the quality of your final products by using staging separation cylinder made by our company, you will be abe to use the cooling emulsion, cutting oil or lubricant repeatedly, you will limit the non-operating states and costs for cleaning the machines choked with metal impurities drastically and mainly you will preserve your production appliance against damage.

SOLLAU – our products are welded by real professionals!

SOLLAU certifications:

Authorization to perform welding on pressure equipment according to PED 2014 / 68 / EU

Pressure welder certificate according to EN-ISO 3834 - 2, EN 1090 - 2, EN 13480 - 1 to 5, EN 13445 - 1 to 5

- Automatic cleaning without a need of interrupting the flow of material

- Large retaing magnetic area

- Trang roller to remove the liquid from separated ferromagnetic particles

- Tilting upper lid

- Inspection window to inspect the separation process

- Litterbin

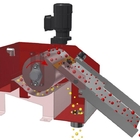

This is the highest version of a magnetic roller for cleaning engineering liquids and it differs from the similar devices used commonly by a special equipment and design. MVS LUX is stepped with a rubber trang roller that presses up an operational liquid out of the ferromagnetic particles being separated. The quantity of the cleaned liquid is increased in this way partly, partly the removed metal contaminants are processed as a valuable secondary raw material more easily. To follow the status of the appliance this trang roller is equiped with an inspection window and also with a tilting upper lid. The vessel for ferromagnetic contaminants caught is an integral part of MVS LUX providing the guarantee of a long-term fluent separation.

Neodymium version

| Product | Maximum capacity of water emulsion (l/min) | Maximum capacity of oil emulsion (l/min) | Working width (mm) | Datasheet |

|---|---|---|---|---|

| MVS-LUX 300 N | 250 | 190 | 325 | display PDF |

| MVS-LUX 500 N | 310 | 230 | 525 | display PDF |

| MVS-LUX 800 N | 380 | 285 | 825 | display PDF |

| MVS-LUX 1000 N | 480 | 360 | 1025 | display PDF |

Ferrite version

| Product | Maximum capacity of water emulsion (l/min) | Maximum capacity of oil emulsion (l/min) | Working width (mm) | Datasheet |

|---|---|---|---|---|

| MVS-LUX 300 F | 250 | 190 | 325 | display PDF |

| MVS-LUX 500 F | 310 | 230 | 525 | display PDF |

| MVS-LUX 800 F | 380 | 285 | 825 | display PDF |

| MVS-LUX 1000 F | 480 | 360 | 1025 | display PDF |

- Automatic cleaning without a need of interruption of the flow of material

- Large interceptive magnetic area

- Low acquisition costs

MVS is a structurally simplified design of the version MVS LUX. When designing this model we tried to make the quality staging roler also to the clients who MSV LUX is too high-priced or unnessesarily sophisticated for. Theresult is MVS that does not dispose of some elůements of special accassories though but from the point of view of efficiency and magnetic power is completely comparable with MVS LUX.

Neodymium version

| Product | Maximum capacity of water emulsion (l/min) | Maximum capacity of oil emulsion (l/min) | Working width (mm) | Datasheet |

|---|---|---|---|---|

| MVS 300 N | 250 | 190 | 325 | display PDF |

| MVS 500 N | 310 | 230 | 525 | display PDF |

| MVS 800 N | 380 | 285 | 825 | display PDF |

| MVS 1000 N | 480 | 360 | 1025 | display PDF |

Ferrite version

| Product | Maximum capacity of water emulsion (l/min) | Maximum capacity of oil emulsion (l/min) | Working width (mm) | Datasheet |

|---|---|---|---|---|

| MVS 300 F | 250 | 190 | 325 | display PDF |

| MVS 500 F | 310 | 230 | 525 | display PDF |

| MVS 800 F | 380 | 285 | 825 | display PDF |

| MVS 1000 F | 480 | 360 | 1025 | display PDF |

Which industrial branches can the magnetic coolant separator be used in?

Machining industry represents an ideal field for the application of the magnetic coolant filter.