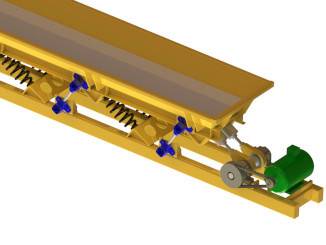

Vibrating conveyor

Vibratory conveyors are a universal solution for transporting a wide variety of bulk materials - from fine dust to stones up to 1 meter in diameter - with minimal wear and maintenance.

Thanks to their robust design, easy cleaning, and reliable operation, they are used in mining, recycling, sand and gravel processing, and other demanding branches.

They ensure a consistent and controlled material flow to downstream technologies and significantly contribute to smooth and efficient operation.

INDUSTRIES: Mineral raw materials, Fasteners, Recycling

- High capacity - for high loads and volumes - ideal for increased performance and smooth operation.

- Heavy-duty design - robust construction (minimum of mechanical parts) = long working life and low operating costs.

- Continuous feed control - feed adjustment from 0% to 100% of preset capacity.

- Size - standard delivery in 9 widths and up to 12 meters in length.

Comprehensive solutions from SOLLAU - magnetic separators, metal detectors, vibrating sieves, and vibrating feeders - all in one place!

KEY FEATURES AND ADVANTAGES OF THE VIBRATING CONVEYOR

- High capacity - a robust solution for handling bulky and heavy material that significantly increases the capacity and productivity of the line.

- Heavy-duty design - construction with troughs of high operational endurance in an abrasive environment, and with a minimum of mechanically stressed components. It significantly extends equipment life and reduces operating costs.

- Size - vibrating conveyor delivery in 9 widths and up to 12 meters in length as standard.

- Continuous feed control - thanks to the electromagnetic drive, the vibrating conveyor enables feed control (adjustable from 0% to 100% of the preset capacity).

- Variable design - open, closed, or dust-tight option to meet stringent environmental requirements.

- Tailored solution - optional inserts, closing gates, sensors, and automation.

WHERE IS THE VIBRATING CONVEYOR USED?

Vibrating conveyors are used in a wide range of industry branches:

- Foundries

- Quarrying of aggregates, sand, and gravel

- Recycling

- Concrete and cement manufacturing

- Production of fasteners

- Coal mining

- Energetics

Customization options

The device can be equipped with optional elements, such as exchangeable inserts, closures, and sensors. All this is for maximum customization to specific operating conditions.

Photo gallery

Other vibrating conveyor

The most common FAQ – Vibrating conveyor

The conveyor can handle everything from fine dust to stones up to 1 meter in diameter with minimal wear and tear.

As standard, we offer solutions up to 12 meters in length, in more than 9 width variants.

The construction is designed with a minimum of mechanical parts. This guarantees a long working life and lower service and maintenance costs.

The electromagnetic drive allows smooth power adjustment from 0 % to 100 %.

Yes, we offer open, closed, and dust-tight designs suitable for all operating conditions.

In foundries, aggregate mining, concrete production, energetics, and recycling.

How does cooperation work?

1.We will come

2.We will measure and design

3.We will manufacture to measure

4.We will install

5.We will commission and train

6.We will provide authorized service

Have a question?

Are you interested in the possibilities of using a vibrating conveyor?

Do you want to discuss modifications, tailoring, or price?

Email us and we will contact you within 24 hours.