Bullet magnets MT

The in-line magnetic separator MT (because of its interior shape sometimes also called “spout magnet”, “pipeline magnet”, “bullet magnet”, “center-flow magnet”, “cartridge magnet” or “air-vey magnet”) is used to separate ferromagnetic particles from materials of poor bulk (pouring) properties (like granulated feeds, plastic granulate, sawdust, powdered materials in the ceramics industry etc.) that could block or clog classic magnetic grate separators.

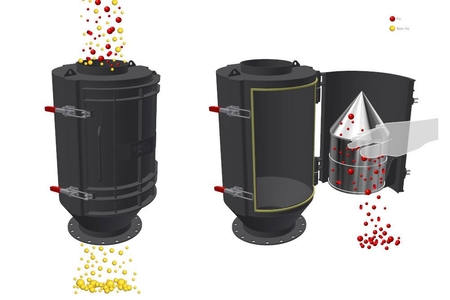

Design of the center-flow magnet

This separator consist of a stainless steel housing that, after being connected to the existing pipeline (e. g. by standard or JACOB flanges), becomes an integral part of the pipeline system.

At the inlet to the separator body there is a dispersion cone arranging for an even distribution of the material flow. In addition, special guiding strips direct the material flow from the inner wall on the magnetic core (located in the lower part of the central magnetic assembly). Since both the cylindrical magnetic assembly with the nose cone as well as the separator housing are of the round shape, there is ensured an even and continuous material flow.

Besides, the round shape of the separator in combination with the dispersion cone and strong ferrite or neodymium magnets make it possible to apply this equipment not only in purely vertical, but also in inclined pipelines.

Which way is the bullet magnet cleaned?

Cleaning the pipe separator is very easy:

- Release the hook clamps.

- Open the door with the integrated magnetic cone.

- Manually remove ferromagnetic contaminants trapped on the magnetic core.

Do not use metal tools to remove trapped contaminants - it could result in an injury!

Customer care

Your project will be taken care of by us from beginning up to the very end. It does not end with the order placed at us. We will provide the full support for all the time of the use of the separator.

1. We will come

2. We will align and design

3. We will make a made-to-measure product

4. We will install

5. We will put into operation and school in

6. We will provide authorized service

We guarantee tests withing three days!

Make sure that our device perfectly meets your expectations!

We will provide tests of your material on our magnetic separators for FREE!

SOLLAU – our products are welded by real professionals!

SOLLAU certifications:

Authorization to perform welding on pressure equipment according to PED 2014 / 68 / EU

Pressure welder certificate according to EN-ISO 3834 - 2, EN 1090 - 2, EN 13480 - 1 to 5, EN 13445 - 1 to 5

- Processing capacity up to 360 m3/h

- Heavy-duty stainless steel design

- Excellent for flow resistant materials

- Manual cleaning

- Vertical installation

Is used to separate ferromagnetic particles from materials of poor bulk (pouring) properties (like granulated feeds, plastic granulate, sawdust, powdered materials in the ceramics industry etc.)

| Product | Maximum capacity (m3/h) | Input/output diameter (mm) | Datasheet |

|---|---|---|---|

| MT 100 F | 10 | 99 | display PDF |

| MT 150 F | 25 | 149 | display PDF |

| MT 200 F | 60 | 199 | display PDF |

| MT 250 F | 90 | 249 | display PDF |

| MT 300 F | 130 | 299 | display PDF |

| MT 350 F | 165 | 349 | display PDF |

| MT 400 F | 230 | 398 | display PDF |

| MT 500 F | 360 | 498 | display PDF |

Which industrial branches can the bullet magnet be used in?

The bullet magnet separator finds application e. g. in the agricultural, pharmaceutical, wood-processing, plastics, chemical and ceramic industry.