Magnetic drums MB

A drum magnet is a device for automatic and permanent removal of magnetic iron metals from inert materials. The permanent magnet systems simplify the separation of ferrous particles, allowing for automatic recovery without production stoppage. At the same time the magnetic drum protects the subsequent machinery (e. g., shredders, mills, grinders) from breakage.

It finds application in recycling, waste and wood processing as well as in the food, cement or lime industry.

Why magnetic drums by SOLLAU?

Why magnetic drums by SOLLAU?

Download PDF

(Size 640 kB)

Design of the magnetic drum

The magnetic drum consists of 2 parts:

- Magnetic core – it is a stationary (= fix) element made from permanent magnets

- The drum shell, revolving on a shaft around the stationary magnetic core, is made from stainless steel and equipped with stainless steel cleats (sometimes also called toppers or carriers).

The processed dry materials are fed into the top of the magnetic drum. The non-magnetic material is not affected by the magnetic field and continues to flow under a normal trajectory in front of the magnetic drum axis. The magnetically susceptible materials are captured by the magnetic field on the rotating shell surface and carried beyond the axis of the magnetic drum. At this point, the ferromagnetic material leaves the magnetic field and falls off or is carried away by the stainless steel cleats (installed on the drum shell for this purpose).

SOLLAU 5 year warranty

We can vouch for the quality of our magnetic separators and that is why why we provide a 5 year warranty on them! Our magnetic separators can be relied on! We are a specialist in the field of magnetic separation.

Magnetic drum strengths

Different applications require different magnetic strengths and these magnetic forces are determined by the type of magnets used in the magnetic core.

We therefore distinguish:

Magnetic drums constructed with ferrite magnets (MB F)

These models are weaker, ideal for separating larger pieces of ferrous tramp metals and strongly magnetic particles.The drum fitted with ferrite magnets is suitable for a large number of separation applications. Its main advantage consists in a lower price.Magnetic drums with neodymium magnets (MB N)

These models are stronger,and thanks to the high strength (also called magnetic induction) of the neodymium magnets are ideal for the separation of fine ferrous particles and weakly magnetic materials.

On the base of the information on your processing capacity, size and type of the treated material etc. our experts are ready to help you configure the magnetic drum (i. e., select the appropriate type of magnets, drum size etc.) so that it meets your individual requirements.

Magnetic drum in a completely enclosed housing

The customer often requires the magnetic drum to be modified so that it can be installed into a customer’s existing pipeline or process. This type of magnetic drum is placed in a housing and its installation is very easy. That is why we have created a complete product line of magnetic drums in housings.

The customer often requires the magnetic drum to be modified so that it can be installed into a customer’s existing pipeline or process. This type of magnetic drum is placed in a housing and its installation is very easy. That is why we have created a complete product line of magnetic drums in housings.

Benefits of using the separator:

- Final material without iron contamination

- Permanent protection of production equipment (crushers, presses, screw conveyors, etc.) from damage by ferrous objects (such as broken machine parts, bolts, nuts, wires, etc.)

- Separation of ferrous particles

- Automatic cleaning - no operator needed

Customer care

Your project will be taken care of by us from beginning up to the very end. It does not end with the order placed at us. We will provide the full support for all the time of the use of the separator.

1. We will come

2. We will align and design

3. We will make a made-to-measure product

4. We will install

5. We will put into operation and school in

6. We will provide authorized service

We guarantee tests withing three days!

Make sure that our device perfectly meets your expectations!

We will provide tests of your material on our magnetic separators for FREE!

Installation of the permanent drum magnet

The magnetic drum can be placed on the output of a conveyor belt or below a hopper (unlike the magnetic pulley the magnetic drum is not an integral part of the conveyor). It is possible to deliver the magnetic drum also in a stainless steel housing with two hoppers under the case. The non-magnetic materials fall into the first hopper and the caught metal impurities are transported on the surface of the drum and fall off beyond the magnetic axis of the drum into the second hopper.

The permanent magnetic drum is really multipurpose, it can collect small as well as big ferromagnetic parts (the dimensions of the drum and the kind of the permanent magnets can be adapted to customer's demands).

The application of ferrite magnets arranges for nearly unlimited working life, however if you need higher magnetic force we recommend that the drum is fitted with extremely powerful neodymium NdFeB magnets (especially in case of the separation of small ferromagnetic particles from materials of worse bulk properties). We deliver the magnetic drum either separately or in a stainless steel housing. If required, the housing can be also equipped with exhaust connector flanges enabling the connection of the machine to client's ventilation system (in order to draw in the separated impurities).

We can also manufacture the housing in robust manganese steel, which will extend several times the service life of the housing even in the most demanding conditions.

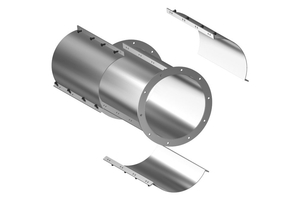

Possible replacement of the wear cover

When separating abrasive materials, the drum cover may wear out. Therefore, we have modified its design so that the user can replace this cover on his own.

As a result, the lifetime of the drum and thus of the entire device will be considerably extended.

Our drum magnets generate a deep and strong magnetic field, so high separation efficiency will be achieved even when the drum is fitted with these additional wear covers.

Replacement of the magnetic drum cover

The magnetic drums are designed in such a way that the wear cover replacement can be carried out through the inspection hole in the drum housing, so there is no need to pull the entire drum out.

The magnetic drums are designed in such a way that the wear cover replacement can be carried out through the inspection hole in the drum housing, so there is no need to pull the entire drum out.

You just replace the individual cover segments successively. It's really simple!

We can also manufacture the housing in robust manganese steel, which will extend several times the service life of the housing even in the most demanding conditions.

Magnetic strength measurement

We pride ourselves on thoroughly testing and measuring the magnetic performance of each separator.

The measurements are made in such a way that they correspond as authentically as possible to real conditions. That is why we do not measure the magnetic flux density (= magnetic induction) only in the magnetic core (as some manufacturers do in order to artificially increase the value of magnetic induction). We also measure the magnetic induction on the drum shell, i. e., at the point of contact with the processed material, what is an important piece of information for the customer.

The information on the measured values can be found in the product datasheets as well as in the section Model family.

And, of course, each supplied magnetic separator is provided with a test report comprising the measured magnetic induction values.

SOLLAU – our products are welded by real professionals!

SOLLAU certifications:

Authorization to perform welding on pressure equipment according to PED 2014 / 68 / EU

Pressure welder certificate according to EN-ISO 3834 - 2, EN 1090 - 2, EN 13480 - 1 to 5, EN 13445 - 1 to 5

MB 154

- MB magnetic drum with a diameter of 154 mm

- The drum with ferrite magnets (axial) MB F - magnetic induction in the core 1 600 G / on the drum shell 1 100 G

- The drum with neodymium magnets (axial) MB N - magnetic induction in the core 5 200 G / on the drum shell 3 400 G

- 5 years warranty

Ferrite version

| Product | Maximum capacity (m3/h) | Working width (mm) | Magnet type | Datasheet |

|---|---|---|---|---|

| MB 154 F 200 | 15 | 150 | Ferrite | display PDF |

| MB 154 F 300 | 20 | 250 | Ferrite | display PDF |

| MB 154 F 400 | 25 | 350 | Ferrite | display PDF |

| MB 154 F 500 | 30 | 450 | Ferrite | display PDF |

| MB 154 F 600 | 35 | 550 | Ferrite | display PDF |

| MB 154 F 700 | 40 | 650 | Ferrite | display PDF |

| MB 154 F 800 | 45 | 750 | Ferrite | display PDF |

| MB 154 F 900 | 50 | 850 | Ferrite | display PDF |

| MB 154 F 1000 | 60 | 950 | Ferrite | display PDF |

Neodymium version

| Product | Maximum capacity (m3/h) | Working width (mm) | Magnet type | Datasheet |

|---|---|---|---|---|

| MB 154 N 200 | 15 | 150 | neodymium | display PDF |

| MB 154 N 300 | 20 | 250 | neodymium | display PDF |

| MB 154 N 400 | 25 | 350 | neodymium | display PDF |

| MB 154 N 500 | 30 | 450 | neodymium | display PDF |

| MB 154 N 600 | 35 | 550 | neodymium | display PDF |

| MB 154 N 700 | 40 | 650 | neodymium | display PDF |

| MB 154 N 800 | 45 | 750 | neodymium | display PDF |

| MB 154 N 900 | 50 | 850 | neodymium | display PDF |

| MB 154 N 1000 | 60 | 950 | neodymium | display PDF |

MB 204

- MB magnetic drum with a diameter of 204 mm

- The drum with ferrite magnets (axial) MB F - magnetic induction in the core 2 600 G / on the drum shell 1 400 G

- The drum with neodymium magnets (axial) MB N - magnetic induction in the core 5 400 G / on the drum shell 3 800 G

- 5 years warranty

Ferrite version

| Product | Maximum capacity (m3/h) | Working width (mm) | Magnet type | Datasheet | MB 204 F 200 | 20 | 150 | Ferrite | display PDF |

|---|---|---|---|---|

| MB 204 F 300 | 25 | 250 | Ferrite | display PDF |

| MB 204 F 400 | 30 | 350 | Ferrite | display PDF |

| MB 204 F 500 | 35 | 450 | Ferrite | display PDF |

| MB 204 F 600 | 40 | 550 | Ferrite | display PDF |

| MB 204 F 700 | 45 | 650 | Ferrite | display PDF |

| MB 204 F 800 | 50 | 750 | Ferrite | display PDF |

| MB 204 F 900 | 60 | 850 | Ferrite | display PDF |

| MB 204 F 1000 | 75 | 950 | Ferrite | display PDF |

Neodymium version

| Product | Maximum capacity (m3/h) | Working width (mm) | Magnet type | Datasheet |

|---|---|---|---|---|

| MB 204 N 200 | 20 | 150 | neodymium | display PDF |

| MB 204 N 300 | 25 | 250 | neodymium | display PDF |

| MB 204 N 400 | 30 | 350 | neodymium | display PDF |

| MB 204 N 500 | 35 | 450 | neodymium | display PDF |

| MB 204 N 600 | 40 | 550 | neodymium | display PDF |

| MB 204 N 700 | 45 | 650 | neodymium | display PDF |

| MB 204 N 800 | 50 | 750 | neodymium | display PDF |

| MB 204 N 900 | 60 | 850 | neodymium | display PDF |

| MB 204 N 1000 | 75 | 950 | neodymium | display PDF |

MB 304

- MB magnetic drum with a diameter of 304 mm

- The drum with ferrite magnets (axial) MB F - magnetic induction in the core 2 800 G / on the drum shell 1 500 G

- The drum with neodymium magnets (axial) MB N - magnetic induction in the core 6 000 G / on the drum shell 3 800 G

- 5 years warranty

Ferrite version

| Product | Maximum capacity (m3/h) | Working width (mm) | Magnet type | Datasheet |

|---|---|---|---|---|

| MB 304 F 200 | 15 | 150 | Ferrite | display PDF |

| MB 304 F 300 | 25 | 250 | Ferrite | display PDF |

| MB 304 F 400 | 35 | 350 | Ferrite | display PDF |

| MB 304 F 500 | 45 | 450 | Ferrite | display PDF |

| MB 304 F 600 | 55 | 550 | Ferrite | display PDF |

| MB 304 F 700 | 65 | 650 | Ferrite | display PDF |

| MB 304 F 800 | 75 | 750 | Ferrite | display PDF |

| MB 304 F 900 | 85 | 850 | Ferrite | display PDF |

| MB 304 F 1000 | 95 | 950 | Ferrite | display PDF |

Neodymium version

| Product | Maximum capacity (m3/h) | Working width (mm) | Magnet type | Datasheet |

|---|---|---|---|---|

| MB 304 N 200 | 15 | 150 | neodymium | display PDF |

| MB 304 N 300 | 25 | 250 | neodymium | display PDF |

| MB 304 N 400 | 35 | 350 | neodymium | display PDF |

| MB 304 N 500 | 45 | 450 | neodymium | display PDF |

| MB 304 N 600 | 55 | 550 | neodymium | display PDF |

| MB 304 N 700 | 65 | 650 | neodymium | display PDF |

| MB 304 N 800 | 75 | 750 | neodymium | display PDF |

| MB 304 N 900 | 85 | 850 | neodymium | display PDF |

| MB 304 N 1000 | 95 | 950 | neodymium | display PDF |

MB 406

- MB magnetic drum with a diameter of 406 mm

- The drum with ferrite magnets (axial) MB F - magnetic induction in the core 2 800 G / on the drum shell 1 500 G

- The drum with neodymium magnets (axial) MB N - magnetic induction in the core 6 000 G / on the drum shell 3 500 G

- 5 years warranty

Ferrite version

| Product | Maximum capacity (m3/h) | Working width (mm) | Magnet type | Datasheet |

|---|---|---|---|---|

| MB 406 F 200 | 25 | 150 | Ferrite | display PDF |

| MB 406 F 300 | 35 | 250 | Ferrite | display PDF |

| MB 406 F 400 | 45 | 350 | Ferrite | display PDF |

| MB 406 F 500 | 55 | 450 | Ferrite | display PDF |

| MB 406 F 600 | 65 | 550 | Ferrite | display PDF |

| MB 406 F 700 | 75 | 650 | Ferrite | display PDF |

| MB 406 F 800 | 90 | 750 | Ferrite | display PDF |

| MB 406 F 900 | 120 | 850 | Ferrite | display PDF |

| MB 406 F 1000 | 140 | 950 | Ferrite | display PDF |

Neodymium version

| Product | Maximum capacity (m3/h) | Working width (mm) | Magnet type | Datasheet |

|---|---|---|---|---|

| MB 406 N 200 | 25 | 150 | neodymium | display PDF |

| MB 406 N 300 | 35 | 250 | neodymium | display PDF |

| MB 406 N 400 | 45 | 350 | neodymium | display PDF |

| MB 406 N 500 | 55 | 450 | neodymium | display PDF |

| MB 406 N 600 | 65 | 550 | neodymium | display PDF |

| MB 406 N 700 | 75 | 650 | neodymium | display PDF |

| MB 406 N 800 | 90 | 750 | neodymium | display PDF |

| MB 406 N 900 | 120 | 850 | neodymium | display PDF |

| MB 406 N 1000 | 140 | 950 | neodymium | display PDF |

MB 506

- MB magnetic drum with a diameter of 506 mm

- The drum with ferrite magnets (axial) MB F - magnetic induction in the core 2 800 G / on the drum shell 1 500 G

- The drum with neodymium magnets (axial) MB N - magnetic induction in the core 6 000 G / on the drum shell 3 400 G

- 5 years warranty

Ferrite version

| Product | Maximum capacity (m3/h) | Working width (mm) | Magnet type | Datasheet |

|---|---|---|---|---|

| MB 506 F 200 | 30 | 150 | Ferrite | display PDF |

| MB 506 F 300 | 45 | 250 | Ferrite | display PDF |

| MB 506 F 400 | 55 | 350 | Ferrite | display PDF |

| MB 506 F 500 | 70 | 450 | Ferrite | display PDF |

| MB 506 F 600 | 85 | 550 | Ferrite | display PDF |

| MB 506 F 700 | 105 | 650 | Ferrite | display PDF |

| MB 506 F 800 | 125 | 750 | Ferrite | display PDF |

| MB 506 F 900 | 145 | 850 | Ferrite | display PDF |

| MB 506 F 1000 | 180 | 950 | Ferrite | display PDF |

Neodymium version

| Product | Maximum capacity (m3/h) | Working width (mm) | Magnet type | Datasheet |

|---|---|---|---|---|

| MB 506 N 200 | 30 | 150 | neodymium | display PDF |

| MB 506 N 300 | 45 | 250 | neodymium | display PDF |

| MB 506 N 400 | 55 | 350 | neodymium | display PDF |

| MB 506 N 500 | 70 | 450 | neodymium | display PDF |

| MB 506 N 600 | 85 | 550 | neodymium | display PDF |

| MB 506 N 700 | 105 | 650 | neodymium | display PDF |

| MB 506 N 800 | 125 | 750 | neodymium | display PDF |

| MB 506 N 900 | 145 | 850 | neodymium | display PDF |

| MB 506 N 1000 | 180 | 950 | neodymium | display PDF |

MB 609

- MB magnetic drum with a diameter of 609 mm

- The drum with ferrite magnets (axial) MB F - magnetic induction in the core 2 800 G / on the drum shell 1 500 G

- The drum with neodymium magnets (axial) MB N - magnetic induction in the core 6 000 G / on the drum shell 3 300 G

- 5 years warranty

Ferrite version

| Product | Maximum capacity (m3/h) | Working width (mm) | Magnet type | Datasheet |

|---|---|---|---|---|

| MB 609 F 300 | 55 | 250 | Ferrite | display PDF |

| MB 609 F 400 | 70 | 350 | Ferrite | display PDF |

| MB 609 F 500 | 85 | 450 | Ferrite | display PDF |

| MB 609 F 600 | 100 | 550 | Ferrite | display PDF |

| MB 609 F 700 | 150 | 650 | Ferrite | display PDF |

| MB 609 F 800 | 190 | 750 | Ferrite | display PDF |

| MB 609 F 900 | 205 | 850 | Ferrite | display PDF |

| MB 609 F 1000 | 220 | 950 | Ferrite | display PDF |

Neodymium version

| Product | Maximum capacity (m3/h) | Working width (mm) | Magnet type | Datasheet |

|---|---|---|---|---|

| MB 609 N 300 | 55 | 250 | neodymium | display PDF |

| MB 609 N 400 | 70 | 350 | neodymium | display PDF |

| MB 609 N 500 | 85 | 450 | neodymium | display PDF |

| MB 609 N 600 | 100 | 550 | neodymium | display PDF |

| MB 609 N 700 | 150 | 650 | neodymium | display PDF |

| MB 609 N 800 | 190 | 750 | neodymium | display PDF |

| MB 609 N 900 | 205 | 850 | neodymium | display PDF |

| MB 609 N 1000 | 220 | 950 | neodymium | display PDF |

Why magnetic drums by SOLLAU?

Why magnetic drums by SOLLAU?

Download PDF

(Size 640 kB)

Which industrial branches can the magnetic drum be used in?

The drum magnets find use in recycling and mining as well as in wood, plastic, ceramic, glass and food industry.

Recycling and waste processing

Machining and foundry industry

Paper industry

Tobacco industry

Ceramic and glass industry

Mining and quarrying industry

Cement and lime industry

Chemical industry, paints and lacquers

Automotive industry

Plastics and rubber industries

Thermal power plants

Wood industry