Self-cleaning pipeline magnetic separators MSP-AC

The MSP-AC SHARK self-cleaning magnetic filter is used for the automatic separation of even very small ferromagnetic impurities from liquid materials (from 1 µm). Thanks to a sophisticated through-flow labyrinth and an automated cleaning system, this separator represents the top among separators, both in the aspect of magnetic separation efficiency and in the aspect of cleaning comfort.

Benefits of using the automated magnetic filter

- Maximum possible separation results even from a liquid with a high content of ferromagnetic contaminants

- Minimization of operating costs

- Minimization of costs needed for hazardous waste disposal

As standard, we produce this pipeline magnet in connecting diameters from 50 to 250 mm. However, we can modify the connecting dimensions and also the connection method (flange, screw-coupling, other special connections) according to your wishes. We equip this magnetic liquid trap with the strongest neodymium magnets with induction of up to 18,700 G on the magnetic core (12,200 G on the casing) and the pull-off force of 176 N!

We are a manufacturer of these magnetic filters. We guarantee top technical performance and a favorable price.

How will the separator cleaning proceed?

Customer care

Your project will be taken care of by us from beginning up to the very end. It does not end with the order placed at us. We will provide the full support for all the time of the use of the separator.

1. We will come

2. We will align and design

3. We will make a made-to-measure product

4. We will install

5. We will put into operation and school in

6. We will provide authorized service

We guarantee tests withing three days!

Make sure that our device perfectly meets your expectations!

We will provide tests of your material on our magnetic separators for FREE!

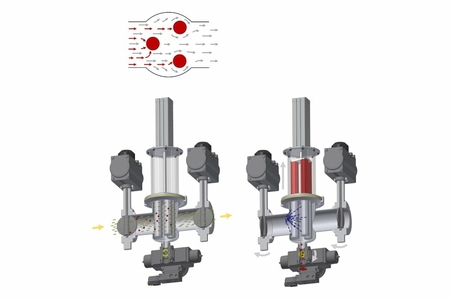

The basis of a magnetic separator with automatic cleaning is a set of magnetic rods, which form a sophisticated through-flow labyrinth. The rods are fitted with the strongest neodymium magnets, which in connection with the through-flow labyrinth create a precondition for successful separation of even very fine ferromagnetic contaminants. The whole cleaning process of the high-intensity magnetic filter is fully automated.

Advantages

- Automatic cleaning proceeds without the need for human operation

- The induction of neodymium magnets reaches up to 12,200 G at the point of contact with the material (i. e. 18,700 G on the magnetic core)

- Capturing Fe particles in size from 1 micron

- Possibility of the cleaning interval setting - frequent cleaning = high quality of separation

- Supplementary secondary separation of rinsing liquid is possible = minimization of costs for hazardous waste disposal = ecological operation

- Possibility of implementation into the pipe bypass

- Interconnection of the control system with the line controlling system is also possible

How will the separator cleaning proceed?

Separator cleaning is fully automated and is ensured by pneumatic elements and a fully programmable separate control unit. The unit is controlled via a touch screen, allowing quick and easy separator setup.

During cleaning, metals trapped on magnetic rods are rinsed with water (or another flushing medium). The metals are then taken away into waste. Where it is not possible to discharge the metals into waste (e.g. for ecological reasons), the second stage of separation will be added to the separator. The metals are discharged into a separative container, where they are separated from the rinse medium. Metal impurities can be easily removed and the flushing medium reused for the next separator cleaning. This will create a closed rinse circuit.

Possible ways of installation of the automated magnetic filters MSP-AC SHARK

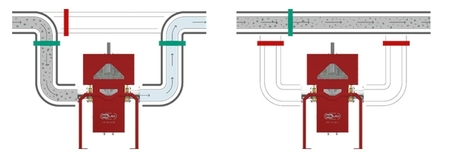

Through-flow separators will be installed in the pipelines. At the moment of separator cleaning, the supply of the separated medium is to be closed. In continuous operations where the material flow cannot be interrupted, we recommend installing a separator into the pipeline bypass. Depending on the degree of medium contamination, one of the 3 installation variants of a magnetic separator should be used in the pipeline bypass (scheme of installation of the automatic MSP-AC – SHARK through-flow separator).

Variant 1 - continuous operation, slightly contaminated medium

The MSP-AC-SHARK automatic separator capturing ferromagnetic impurities is installed into the pipeline bypass. During the cleaning cycle, the separated medium flows through a pipeline being not equipped with a magnetic separator. Thus, the medium is not cleaned during this time.

- +: lower price

- +: suitable for slightly contaminated media

- -: at the moment of the separator cleaning the medium WILL BE NOT SEPARATED

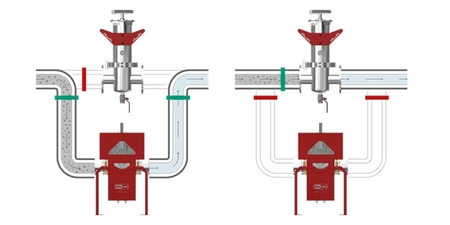

Variant 2 - continuous operation, medium-contaminated material

The MSP-AC-SHARK automated magnetic filter capturing ferromagnetic impurities is installed into the pipeline bypass. During the cleaning cycle, the separated medium flows through a pipeline, being equipped with the MSP-MC – PIRANHA magnetic trap. The medium is separated also during the cleaning.

- +: continuous separation

- +: suitable for medium-contaminated material

- -: as to a heavily contaminated medium, the MSP-MC separator may soon be clogged with ferromagnetic impurities, reducing its efficiency.

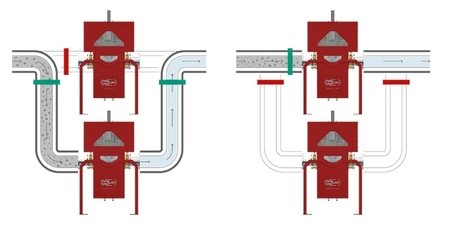

Variant 3 - continuous operation, heavily contaminated medium

The MSP-AC-SHARK self-cleaning magnetic filter capturing ferromagnetic impurities will be installed into the pipeline bypass. During the cleaning cycle, the separated medium is flown through a pipeline, being equipped with the MSP-AC-SHARK ferrous trap. The medium is separated also during the cleaning - with the same quality as with the primary separator.

SOLLAU – our products are welded by real professionals!

SOLLAU certifications:

Authorization to perform welding on pressure equipment according to PED 2014 / 68 / EU

Pressure welder certificate according to EN-ISO 3834 - 2, EN 1090 - 2, EN 13480 - 1 to 5, EN 13445 - 1 to 5

- High pull-off force (up to 176 N)

- High efficiency (up to 15 magnetic tubes)

- Magnetic tubes with a diameter of 32 mm

- A AMIT-designed control system, pneumatic components by FESTO

- Wide range of optional accessories (remote management, sight glass, flow meter, etc.)

- Two-stage separation - adding a separation container is possible

Automatic separator equipment

- FESTO pneumatic parts

- AMIT-designed control system

- Color touch screen control

- Optical signaling of the cleaning cycle and break-downs

- Furthermore, a number of additional equipment (flow meter, inlet pressure monitoring of the separated material, sight glass for visual inspection, …)

- Possibility of remote management

- Another additional equipment

The color touch LED display allows

- Separator's full control of the START / STOP / TEST functions

- Control of connected devices - e.g. separation container

- Cleaning interval set up

- Execution of the test cleaning cycle

- Setting the length of individual cleaning steps (rinsing length, discharge of good material, blowing of tubes with compressed air, …)

- Error reporting

- Statistics

- Several other functionalities

| Product | Connecting diameter (mm) | Datasheet |

|---|---|---|

| MSP-AC 50 N SHARK | 50 | display PDF |

| MSP-AC 100 N SHARK | 100 | display PDF |

| MSP-AC 150 N SHARK | 150 | display PDF |

| MSP-AC 200 N SHARK | 200 | display PDF |

| MSP-AC 250 N SHARK | 250 | display PDF |

We produce magnetic separators in these three levels of magnetic induction

Which industrial branches can the automated magnetic filter be used in?

The self-cleaning magnetic filter MSP-AC for pipeline transport is designed to handle heavy contamination at inconvenient locations and can be integrated in a fully automatized production line, what ensures a high effectiveness of the production process. The trap magnet MSP-AC for pipeline transport (with automatic cleaning) finds use in engineering as well as in sugar, food, pharmaceutical, chemical and ceramic industries.