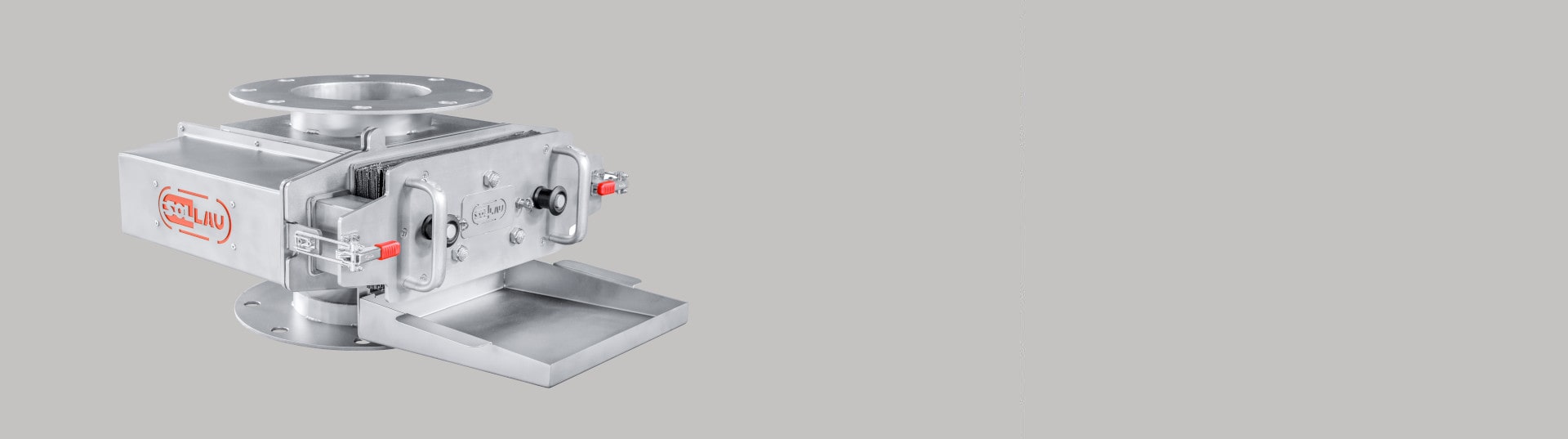

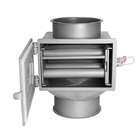

Magnetic grate separators in housing MSS-MC

A drawer magnet is designed to separate in a quick and easy way magnetic iron contamination from free-flowing substances of good bulk properties and to protect the machinery that subsequently treats these materials.

Benefits of using the separator

- Material without the ferromagnetic admixtures

- Permanent protection of technological machinery

- Fluent process operation

Why magnetic grate separators in housing by SOLLAU?

Why magnetic grate separators in housing by SOLLAU?

Download PDF

(Size 768 kB)

Customer care

Your project will be taken care of by us from beginning up to the very end. It does not end with the order placed at us. We will provide the full support for all the time of the use of the separator.

1. We will come

2. We will align and design

3. We will make a made-to-measure product

4. We will install

5. We will put into operation and school in

6. We will provide authorized service

We guarantee tests withing three days!

Make sure that our device perfectly meets your expectations!

We will provide tests of your material on our magnetic separators for FREE!

Design of the grate magnet in housing

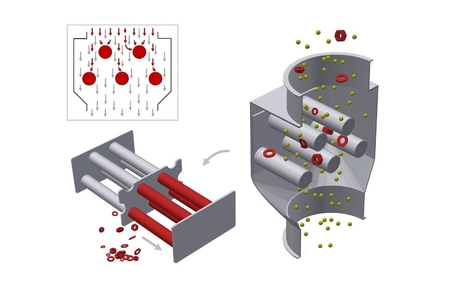

The basic elements of the magnetic grate separator in housing are one or two rows of magnetic grates (consisting of stainless steel tubes). While the material flows over the magnetic tubes, a very strong magnetic field (generated by the neodymium NdFeB magnets inside of the tubes) traps all metallic particles on the surface of the tubes. The magnetic grates inside of the housing are placed one above the other and the upper set of tubes consists of one tube less. The grate sieve - created in this way – is in a very intensive contact with the flowing material, can capture even the smallest ferromagnetic impurities and guarantees an extremely high separation efficiency. The captured metal contaminants are pushed to the underside of the tube where they are out of contact with the product flow preventing washoff back in to the clean material.

What pipeline is the drawer-in-housing connected to?

In order to ensure a quick and easy connection, the separator housing is standardly ended by flanges (standard type, Jacob quick-connect fasteners or flanges according to client's needs) in sizes from 100 to 300 mm, but we can adjust the connection type as well as its size and the inbuilt height to client's requirements.

We offer the drawer magnets in three different surface finishes:

- sandblasted (Ra 1.6 µm)

- internally polished (Ra 0.14 µm)

- fully polished (Ra 0.14 µm)

SOLLAU – our products are welded by real professionals!

SOLLAU certifications:

Authorization to perform welding on pressure equipment according to PED 2014 / 68 / EU

Pressure welder certificate according to EN-ISO 3834 - 2, EN 1090 - 2, EN 13480 - 1 to 5, EN 13445 - 1 to 5

- Two-stage separation

- Magnetic core kink-protection sleeve

- Easy, quick and safe cleaning

- Big variability of connexion

- 18 700 Gauss on the magnetic core and 12 200 Gauss on the lateral area

The uniqueness of the technical solution of this model consists in the system of the magnetic grate moving on telescopic slides and also in the extraordinary protection of the magnetic cores. Thanks to its placing on the guiding drives, the entire magnetic grid is an integral part of the magnetic separator and handling the magnetic grid as well as and the magnetic bars (during the cleaning) is therefore effortless.

Besides, the magnetic cores are permanently protected by a special accordion cover, simultaneously performing three functions during the separator cleaning:

- It prevents unwanted skipping the ferromagnetic contaminants from the surface of the stainless steel grate onto the magnetic cores.

- It protects the magnetic cores e.g. before dusting (with the cleaned material, etc.).

- It eliminates the risk of contaminating the cleaned material by e. g. a piece of a chipped magnetic core or its surface coating.

The separator is also provided with inspection holes (sight glasses) on the sides, so that both the material flow and the amount of captured Fe contaminants can be visually checked. On a special request, the separator can also be equipped with a shutting flap for a manual interruption of the material flow into the separator, with a safety lock etc.

We are able to manufacture this magnetic separator with the maximum induction of 18 700 G on the core and 11 700 G on the magnetic pipe sheating. Tolerance is +/- 10 %.

| Product | Maximum capacity (m3/h) | Input/output diameter (mm) | Datasheet |

|---|---|---|---|

| MSS-MC LUX 100/3 N | 4 | 99 | display PDF |

| MSS-MC LUX 120/3 N | 4 | 119 | display PDF |

| MSS-MC LUX 100/5 N | 4 | 99 | display PDF |

| MSS-MC LUX 150/5 N | 7 | 149 | display PDF |

| MSS-MC LUX 200/5 N | 8 | 199 | display PDF |

| MSS-MC LUX 200/7 N | 8 | 199 | display PDF |

| MSS-MC LUX 250/9 N | 11 | 249 | display PDF |

| MSS-MC LUX 300/9 N | 15 | 299 | display PDF |

We produce magnetic separators in these three levels of magnetic induction

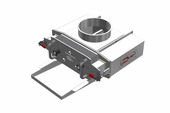

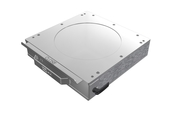

- Two-stage separation

- Front sight-glass

- Withdrawable grate

- Big variability of connexion

- 18 700 Gauss on the magnetic core and 12 200 Gauss on the lateral area

This is a conventional design where the magnetic grates are installed crosswise with respect to the entrance door. The material flow as well as the tube contamination status can be checked thanks to an inspection window.

The grates can be taken out of the separator (e. g. for cleaning) and afterwards cleaned very easily and quickly (as the ferromagnetic particles drop away off the grate tube surface spontaneously as soon as the magnetic cores are manually pulled out of the stainless steel tubes).

We are able to manufacture this magnetic separator with the maximum induction of 18 700 G on the core and 11 700 G on the magnetic pipe sheating. Tolerance is +/- 10 %.

| Product | Maximum capacity (m3/h) | Input/output diameter (mm) | Datasheet |

|---|---|---|---|

| MSS-MC 100/3 N | 4 | 99 | display PDF |

| MSS-MC 120/3 N | 4 | 119 | display PDF |

| MSS-MC 100/5 N | 4 | 99 | display PDF |

| MSS-MC 150/5 N | 7 | 149 | display PDF |

| MSS-MC 200/5 N | 8 | 199 | display PDF |

| MSS-MC 200/7 N | 8 | 199 | display PDF |

| MSS-MC 250/9 N | 11 | 249 | display PDF |

| MSS-MC 300/9 N | 15 | 299 | display PDF |

We produce magnetic separators in these three levels of magnetic induction

Some products from this model family are available for immediate purchase. We are constantly extending the offer of our magnetic separators in stock so that we can deliver them to you immediately. Please, contact our dealer to inform for their current availability.

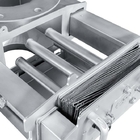

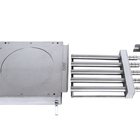

- Two-stage separation

- Massive grate construction enabling the safe manipulation

- Grate can be eqipped with the interposer bars making the cleaning process easier

- Innovative design to prevent material sticking inside the separator

- Big variability of connexion

- 18 700 Gauss on the magnetic core and 12 200 Gauss on the lateral area

This innovated separator has the magnetic grates placed parallelly to the door opening, unlike the standard grate separator. The advantage of this design consists above all in the fact that the separators of larger dimensions can be equipped with guiding bars which will make heavy magnetic grate handling easier.

Moreover, the internal structure of this special separator has been modified in order to limit undesirable material accumulation in any part of the separator (which is important e. g. in order to comply with the strict hygienic requirements referring to food processing or pharmaceutical applications).

We are able to manufacture this magnetic separator with the maximum induction of 18 700 G on the core and 11 700 G on the magnetic pipe sheating. Tolerance is +/- 10 %.

| Product | Maximum capacity (m3/h) | Input/output diameter (mm) | Datasheet |

|---|---|---|---|

| MSS-MC IN 100/3 N | 4 | 99 | display PDF |

| MSS-MC IN 120/3 N | 4 | 119 | display PDF |

| MSS-MC IN 100/5 N | 4 | 99 | display PDF |

| MSS-MC IN 150/5 N | 7 | 149 | display PDF |

| MSS-MC IN 200/5 N | 8 | 199 | display PDF |

| MSS-MC IN 200/7 N | 8 | 199 | display PDF |

| MSS-MC IN 250/9 N | 11 | 249 | display PDF |

| MSS-MC IN 300/9 N | 15 | 299 | display PDF |

We produce magnetic separators in these three levels of magnetic induction

- One-stage separation

- Low building height of 50 mm

- JACOB connexion

- Low acquisition costs

- 9 000 Gauss on the magnetic core and 5 200 Gauss on the lateral area

This budget-wise version of the box separator does not offer all options provided by standard magnetic box separators, however, on the other hand, it has several indisputable advantages. It is ideal for applications in piping systems where MSS-MC or MSS-MC IN could not be installed because of height limitations.

The installation height of MSS-MC EKO is only 50 mm, so this separator can be used nearly at any application place. Both-sided standard JACOB flanges ensure easy and quick fastening and that is why hopper outlets, tube end pieces for big bag filling etc. are very suitable fields for the application of MSS-MC EKO (and its selling price is also very attractive). Its disadvantages consist in a lower capacity (it is only a single grate separator with narrower tubes, and that is why it is suitable for less contaminated materials) and the necessity of taking the separator out of the piping system during the cleaning (of course, only if it is installed in a pipeline and not e. g. at a hopper outlet.

| Product | Maximum capacity (m3/h) | Internal diameter (mm) | Datasheet |

|---|---|---|---|

| MSS-MC EKO 100 N | 1,5 | 99 | display PDF |

| MSS-MC EKO 150 N | 3 | 149 | display PDF |

| MSS-MC EKO 200 N | 4,5 | 199 | display PDF |

| MSS-MC EKO 250 N | 7 | 249 | display PDF |

- Two-stage separation

- Low building height

- Robust design = high separator load

- Slide gate to interrupt material flow

- 9 000 Gauss on the magnetic core and 6 000 Gauss on the lateral area

This special grate magnetic separator is fitted with exceptionally robust (but at the same time also lightweight) steel flange, it has a very low built-up height and is provided with a flap for manual interruption of the material flow into the separator. All these parameters predefine this separator for the plants or lines where the central interruption of the material flow into the separator could be problematic or unsuitable.

The robust design at the same time guarantees that the separator will resist to even very high weight load. Other parameters are similar as those of MSS-MC IN, i.e. the separator has magnetic grates mounted in the direction of entrance door opening so that the grates can be pulled out from the separator for cleaning and cleaned easily a quickly. The separator is intended primarily for piping applications in the plastic industry (it is to be positioned in front of injection moulding presses, extrusion machines, etc.).

| Product | Internal diameter (mm) | Datasheet |

|---|---|---|

| MSS-MC HL 100/3 N | 100 | display PDF |

| MSS-MC HL 150/5 N | 150 | display PDF |

| MSS-MC HL 200/7 N | 200 | display PDF |

| MSS-MC HL 250/9 N | 250 | display PDF |

| MSS-MC HL 300/9 N | 300 | display PDF |

- Two-stage separation

- JACOB connexion

- Low acquisition costs

- 16 000 Gauss on the lateral area

It is an economical but at the same time fully functional version of the magnetic grate separator for applications in JACOB piping systems. The separator is terminated on both sides with JACOB flanges (with the diameter ranging from 100 mm to 300 mm), however, when compared with standard grate separators, it is cheaper, lighter and has also a lower built-up height. Moreover, a round body of the separator ensures smooth flow of material through the separator (undesirable material sticking or accumulation inside of the separator does not take place).

The separator has magnetic grates mounted in the direction of entrance door opening so that the grates can be pulled out from the separator for cleaning and cleaned easily and quickly. Thanks to the termination with the JACOB flanges, this separator has multi-sector utilization (it can be applied e.g. behind exhaustion device or dust separator).

| Product | Internal diameter (mm) | Datasheet |

|---|---|---|

| MSS-MC COMPACT 100/3 N | 99 | display PDF |

| MSS-MC COMPACT 150/5 N | 149 | display PDF |

| MSS-MC COMPACT 200/7 N | 199 | display PDF |

| MSS-MC COMPACT 250/9 N | 249 | display PDF |

| MSS-MC COMPACT 300/9 N | 299 | display PDF |

- Two-stage separation

- Equipped with an electric vibratory system

- For materials of bad flow properties with a tendency to arching or bridging

- Great variability of connections

- 18 700 Gauss on the magnetic core and 12200 Gauss at the point of contact with the processed material

This separator is exceptional in that it provides the advantages of a grate separator (i.e. high magnetic induction, high separation quality), but at the same time it is suitable also for the separation of ferrous particles from bulk materials of bad flow properties (that tend to bridge and that is why they would block the standard grate separators).

The magnetic separator is fitted with a vibrating electric motor, located on the outside of the separator housing. The vibration prevents the magnetic grates from becoming clogged with the treated material. Thanks to this, the magnetic separation is of high quality and the flow of material through the separator is smooth.

The separator is designed so that the separator vibrations do not affect the surrounding technologies.

Why magnetic grate separators in housing by SOLLAU?

Why magnetic grate separators in housing by SOLLAU?

Download PDF

(Size 768 kB)

Which industrial branches can the grate magnet in housing be used in?

Drawer magnets are mostly used in the area of recycling and waste treatment, food processing, pharmaceutics, wood processing, plastic industries, mining and mineral processing, industrial production of ceramics and glass etc.