Vibration table

Vibrating tables are intended for efficient compaction and settling of bulk or cast materials in containers, molds, or packages.

Their use ensures optimum volume filling, elimination of air pockets, and achievement of the desired product density.

Their wide range of customization options, robust design, and high performance make them ideal for deployment in automated as well as manual production lines.

INDUSTRIES: Mineral raw materials, Connection accessories, Recycling

- Compaction - they eliminate air pockets and ensure uniform material settlement. They are ideal for achieving the desired product density.

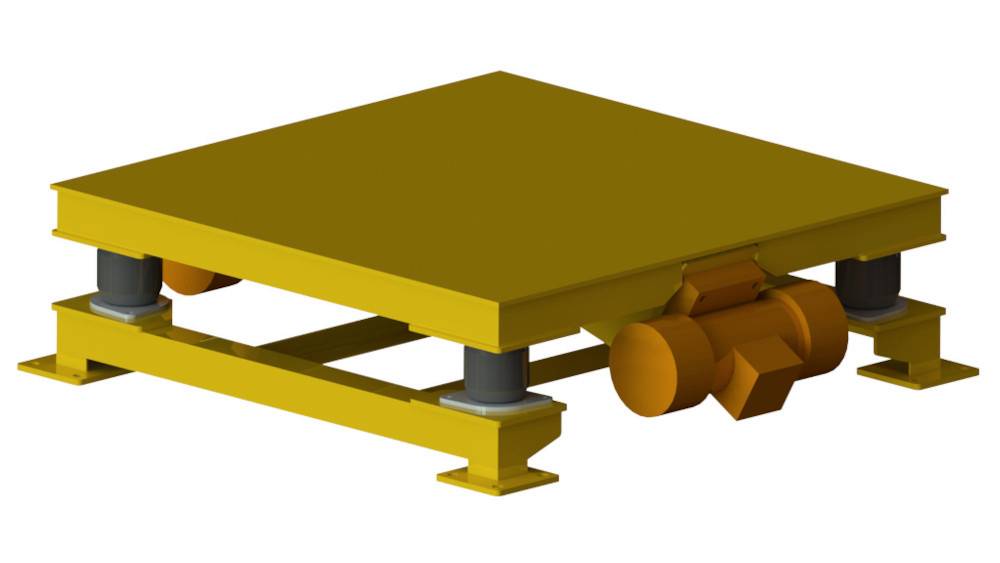

- Resistant design - robust construction for harsh conditions, resistant to static as well as dynamic loads.

Comprehensive solutions from SOLLAU - magnetic separators, metal detectors, vibrating sieves, and vibrating feeders - all in one place!

KEY FEATURES AND ADVANTAGES OF THE VIBRATING TABLE

- Volume optimization - uniform distribution and material compaction ensure maximum space utilization in containers and molds.

- Increase in output quality - minimization of air pockets and product inhomogeneities through precise vibration effect.

- Wide design variability - tables can be modified according to the desired size, vibration type (vertical, horizontal, or combined), and control type.

- Dimensions - it can handle material up to 2 meters in height and up to 10 meters in length.

- Line integration - ideal for both fully automated systems and stand-alone workstations.

- Robust construction - designed to operate in a demanding environment. It can handle static material loading as well as dynamic stresses.

WHERE IS THE VIBRATING TABLE USED?

Vibrating tables are used in a wide range of industry branches:

- compaction of concrete prefab components,

- compaction of foundry sand,

- production of fastening components,

- quarrying and processing of aggregate, sand, and gravel,

- cement plants and building material production facilities,

- glass production,

- automotive industry.

Customization options

Each vibrating table can be configured to meet specific customer requirements:

- dimensions of the work surface and the table height,

- vibration type (linear, rotary, or combined),

- power and vibration frequency,

- control type (manual, remote, or PLC-integrated),

- possibility of integration into automated processes.

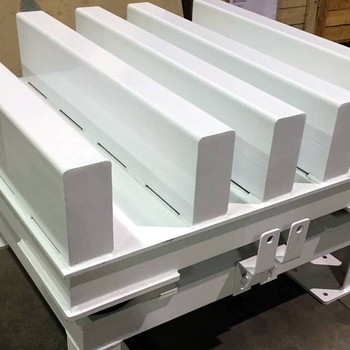

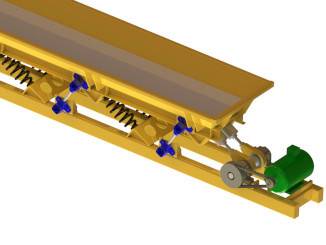

Photo gallery

Other vibration table

The most common FAQ – Vibration table

It is used for the compaction and even settling of bulk or poured materials in various molds, packages, or containers.

Pomocí vibrací odstraňuje vzduchové kapsy a zajišťuje rovnoměrné rozložení materiálu, což vede ke stabilní hustotě výrobku.

Yes. There is a possibility to configure the surface size, vibration type (vertical, horizontal, or combined), and the control type (manual, remote, and PLC).

The vibrating table can handle materials up to 2 meters in height and 10 meters in length, including both static and dynamic loads.

Yes. Its robustness and configurability make it ideal for fully automated plants and stand-alone workplaces.

They are applied in the production of concrete parts, foundries, mining, glass production, and the automotive industry.

How does cooperation work?

1.We will come

2.We will measure and design

3.We will manufacture to measure

4.We will install

5.We will commission and train

6.We will provide authorized service

Have a question?

Are you interested in the possibilities of using a vibrating conveyor?

Do you want to discuss modifications, tailoring, or price?

Email us and we will contact you within 24 hours.