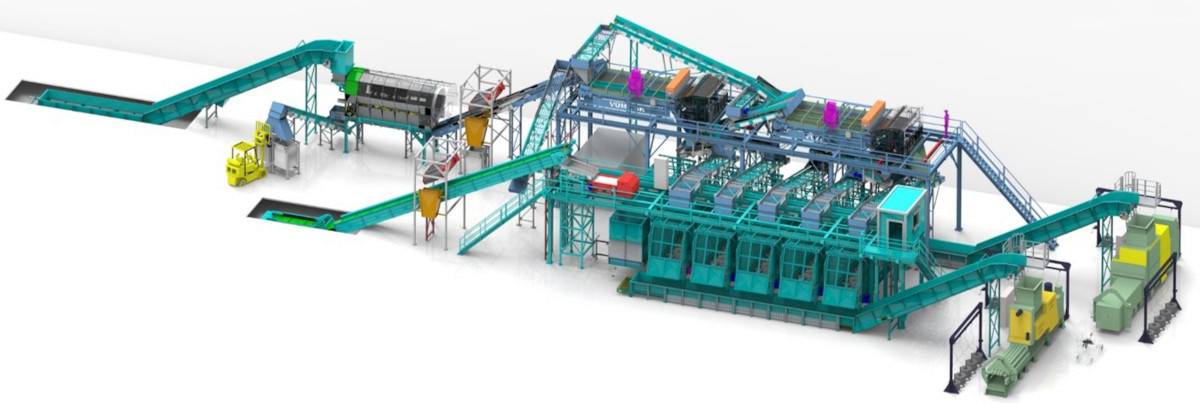

Automated line for sorting PET bottles, Al and Fe cans

This automatic sorting line is designed for a capacity of 4,500 kg/hour and is used to treat waste material kept in “yellow bins”, i.e. PET bottles, aluminum and iron cans.

Firstly, material bales are unpacked and the material passes through a trommel screen.

Afterwards, ferrous cans are separated by a pair of very strong DND-AC TIGER overband magnets.

The reliable separation of aluminum cans is performed using the ECS-C RAM eddy current separator with a concentric rare earth rotor. Before being processed by the ECS separator, the material is spread on the conveyor belt by a vibrating feeder (the uniform material distribution is a prerequisite for the proper functioning of the ECS separator).

Finally, the PET bottles are sorted by color using a NIR / VIS spectrophotometer.

The individual types of the sorted materials are pressed.

The functionality of the entire sorting line and its parts is monitored by a camera system. The advantage of such a system is the possibility of remote access to individual control elements of the sorting line.

- The separation line capacity: 4.5 t/h + 3.5 t/h (Al packaging)

- Guaranteed separation

Output

The treated waste is sorted into the following material fractions:

- 3D PET bottles

- Aluminum cans

- Iron cans

The sorting line consists of the following equipment:

- Conveying system

- ECS-C 1000 RAM eddy current separator with centrically mounted rotor - for conveyor belts of 1,000 mm width

- NIR / VIS spectrophotometer

- Trommel screen

- Accumulation storage boxes

- Automatic baler

- Crushers

- Steel construction

- Complex control system with PLC outputs directly on the sorting line

- Remote access

- Camera surveillance