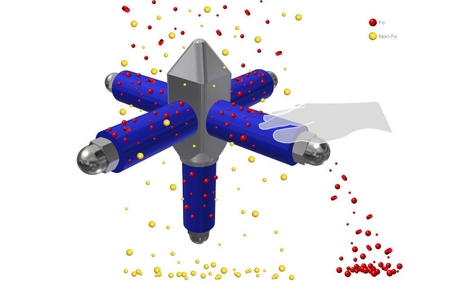

Star-shaped hopper magnets SM

A magnetic grate of a star design for the hoppers of injection moulding machines is intended for the separation of iron tramp from free-flowing dry materials (such as regranulates, crushed plastic materials, plastic crumb, rejected mouldings etc.). The magnetic grid protects the moulding machines (with standard cone hoppers) and other processing equipment from damage by ferromagnetic particles.

While the bulk powder material falls through the grid magnet, a very strong magnetic field (generated by neodymium NdFeB magnets of the hopper magnet) traps all metallic particles on the surface of the neo magnets. Thanks to the magnets made from rare earth ores the magnetic impurities captured on the tubes are not carried away by the stream of the continually poured material (what happens in case of separators fitted with weaker black ferrite magnets).

How is star-shaped hopper magnet cleaned?

During the cleaning procedure the grate magnet is taken out of the hopper and the captured ferromagnetic particles are removed either mechanically or by a stream of compressed air. The star-shaped hopper magnet is very effective, but also easy to install and transport (from one application place to another), practically maintenance-free and inexpensive to acquire and operate. The design as well as the size of the star-shaped magnetic grid for plastic extrudes & injection moulding machines can be adjusted to client's requirements.

Easy placing an order in e-shop

Customer care

Your project will be taken care of by us from beginning up to the very end. It does not end with the order placed at us. We will provide the full support for all the time of the use of the separator.

1. We will come

2. We will align and design

3. We will make a made-to-measure product

4. We will install

5. We will put into operation and school in

6. We will provide authorized service

We guarantee tests withing three days!

Make sure that our device perfectly meets your expectations!

We will provide tests of your material on our magnetic separators for FREE!

SOLLAU – our products are welded by real professionals!

SOLLAU certifications:

Authorization to perform welding on pressure equipment according to PED 2014 / 68 / EU

Pressure welder certificate according to EN-ISO 3834 - 2, EN 1090 - 2, EN 13480 - 1 to 5, EN 13445 - 1 to 5

- Budget version (attractive price/performance ratio)

- High pull strength

- Manual cleaning

- Original design for round hoppers

Is designed to separate iron tramp from free-flowing dry materials (such as regranulates, crushed plastic materials, plastic crumb, rejected mouldings etc.).

| Product | Diameter (mm) | Datasheet |

|---|---|---|

| SM 150 N | 150 | display PDF |

| SM 200 N | 200 | display PDF |

| SM 250 N | 250 | display PDF |

| SM 300 N | 300 | display PDF |

| SM 350 N | 350 | display PDF |

Some products from this model family are available for immediate purchase. We are constantly extending the offer of our magnetic separators in stock so that we can deliver them to you immediately. Please, contact our dealer to inform for their current availability.

Which industrial branches can the star-shaped grid magnet be used in?

The hopper magnets find use e. g. in recycling and plastic industry.