Hopper magnets TM

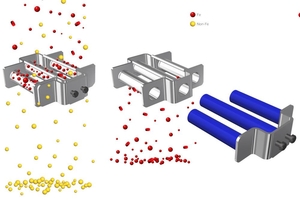

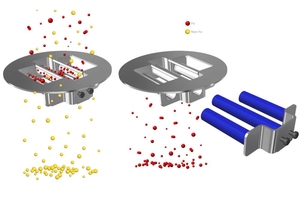

Magnetic separator for the hoppers of injection moulding machines s designed to separate iron tramp from free-flowing dry materials (such as regranulates, crushed plastic materials, plastic crumb, rejected mouldings etc.). The hopper magnet protects the moulding machines (with standard cone hoppers) and other processing equipment from damage by ferromagnetic particles.

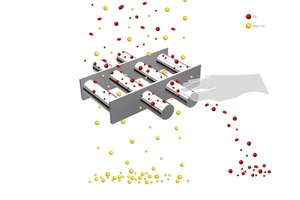

How does the magnetic grate work?

While the bulk powder material falls through the magnetic tubes, a very strong magnetic field (generated by neodymium NdFeB magnets situated inside of the tubes) traps all metallic particles on the surface of the grids. Thanks to the neo magnets the magnetic impurities captured on the tubes are not carried away by the stream of the continually poured material (what happens if separators are fitted with weaker black ferrite magnets). Unlike some competing separators equipped with weaker ferrite magnets.

Types of hopper magnets for plastic injection molding machines

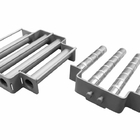

Hopper magnet TM for plastic injection molding machines

- Neodymium magnets - 9000 G on the magnetic core and up to 6000 G on the stainless steel protective tubes

- Tube diameter of 22 mm

- 7 dimensional types for the hopper diameters from 100 to 400 mm

- Easy cleaning system - cleaning is performed by sliding the magnetic cores out of the stainless steel housings, the trapped ferrous particles easily fall off

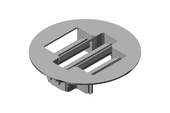

Hopper magnet TM FL with a collar for plastic injection molding machines

- Integrated plate hopper ensures that 100 % of the processed material will come into contact with the magnetic tubes = the highest quality of separation. At the same time it prevents from the material leakage over the hopper magnet edge.

- Neodymium magnets - 9000 G on the magnetic core and up to 6000 G on the stainless steel protective tubes

- Tube diameter of 22 mm

- 7 dimensional types for the hopper diameters from 100 to 400 mm

- Easy cleaning system - cleaning is performed by sliding the magnetic cores out of the stainless steel housings, the trapped ferrous particles easily fall off

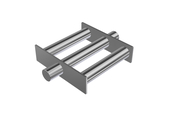

Hopper magnet TM EKO for plastic injection molding machines

- Budget version (attractive price/performance ratio)

- Neodymium magnets - up to 13 500 Gauss on the stainless steel protective tubes

- Tube diameter of 25 mm

- 3 dimensional types for the hopper diameters from 150 to 250 mm

- Manual cleaning - trapped metals must be removed manually

How to clean hopper magnets for plastic injection molding machines?

The cleaning is performed by pulling the neodymium magnetic cores out of the stainless steel tubes. The trapped contamination will subsequently fall away. Compared to the hopper magnets without the easy cleaning system, needing to be blown laboriously and whose cleaning is considerably inefficient and lengthy, our design offers not only high efficiency of the separation itself but also simple operation and cleaning.

Advantages of a hopper magnet

Our hopper magnets are not only very effective, but also easy to clean, install and transport (from one application place to another), practically maintenance-free and inexpensive to acquire and operate.

Easy placing an order in e-shop

Customer care

Your project will be taken care of by us from beginning up to the very end. It does not end with the order placed at us. We will provide the full support for all the time of the use of the separator.

1. We will come

2. We will align and design

3. We will make a made-to-measure product

4. We will install

5. We will put into operation and school in

6. We will provide authorized service

We guarantee tests withing three days!

Make sure that our device perfectly meets your expectations!

We will provide tests of your material on our magnetic separators for FREE!

What pipeline is the grate magnet connected to?

The hopper magnet for plastic extrudes & injection moulding machines is standardly manufactured in diameters from 100 to 400 mm, but we can adjust its design as well as the size to client's requirements.

SOLLAU – our products are welded by real professionals!

SOLLAU certifications:

Authorization to perform welding on pressure equipment according to PED 2014 / 68 / EU

Pressure welder certificate according to EN-ISO 3834 - 2, EN 1090 - 2, EN 13480 - 1 to 5, EN 13445 - 1 to 5

- Quick and easy cleaning thanks to the system of telescopic magnetic tubes

- 9000 Gauss on the magnetic core and up to 6000 Gauss on the stainless steel protective cover

- Fix dispersion cones (for better spreading of the material on the surface of the magnetic tubes)

Is designed to separate iron tramp from free-flowing dry materials (such as regranulates, crushed plastic materials, plastic crumb, rejected mouldings etc.).

| Product | Diameter (mm) | Datasheet |

|---|---|---|

| TM 100 N | 100 | display PDF |

| TM 150 N | 150 | display PDF |

| TM 200 N | 200 | display PDF |

| TM 250 N | 250 | display PDF |

| TM 300 N | 300 | display PDF |

| TM 350 N | 350 | display PDF |

| TM 400 N | 400 | display PDF |

Some products from this model family are available for immediate purchase. We are constantly extending the offer of our magnetic separators in stock so that we can deliver them to you immediately. Please, contact our dealer to inform for their current availability.

- Integrated plate hopper prevents from the material leakage over the hopper magnet edge

- Better separation efficiency

- Quick and easy cleaning thanks to the system of telescopic magnetic tubes

- 9000 Gauss on the magnetic core and up to 6000 Gauss on the stainless steel protective cover

- Fix dispersion cones (for better spreading of the material on the surface of the magnetic tubes)

The flanged version has two significant advantages. The material flow is directed to the center of the separator, i. e., to the magnetic tubes. The round flange matches the round shape of the hopper and that is why it prevents any unwanted leakage of the contaminated material alongside the separator edges.

| Product | Diameter (mm) | Datasheet |

|---|---|---|

| TM FL 100 N | 100 | display PDF |

| TM FL 150 N | 150 | display PDF |

| TM FL 200 N | 200 | display PDF |

| TM FL 250 N | 250 | display PDF |

| TM FL 300 N | 300 | display PDF |

| TM FL 350 N | 350 | display PDF |

| TM FL 400 N | 400 | display PDF |

- Budget version (attractive price/performance ratio)

- High pull strength

- Up to 13 500 Gauss on the stainless steel protective cover

- Only polished design

- Manual cleaning

Magnetic separator TM-EKO for the hoppers of injection moulding machines is designed to separate ferromagnetic particles from free-flowing dry materials. The basic elements the magnetic grate consists of are polished magnetic tubes (made from stainless steel). While the bulk powder material falls through the magnetic tubes, a very strong magnetic field captures all ferrous particles on the surface of the grids. As there is no easy cleaning system at the EKO version, the captured Fe particles are removed manually from the surface of the magnetic tubes. On the other hand, the combination of the extremely strong magnets (N52) with only one layer of the very thin protective stainless steel cover arranges for an extremely high magnetic induction on the surface of this separator (about 13 500 G).

| Product | Diameter (mm) | Datasheet |

|---|---|---|

| TM EKO 150 N | 150 | display PDF |

| TM EKO 200 N | 200 | display PDF |

| TM EKO 250 N | 250 | display PDF |

Some products from this model family are available for immediate purchase. We are constantly extending the offer of our magnetic separators in stock so that we can deliver them to you immediately. Please, contact our dealer to inform for their current availability.

Which industrial branches can the magnetic grid be used in?

The telescopic magnetic grates find use e. g. in recycling and plastic industry.