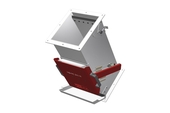

Magnetic chute MS-MC

The magnetic chute MS-MC is designed for inclined pipeline systems, where the application of other types of the magnetic separators would be difficult or even impossible. In order to achieve optimal separation results, the angle of the pipeline, in which the plate magnet is mounted, should not exceed 40° from the vertical.

The magnetic chutes are available in several versions with different strengths of the magnetic field (ferritic, weaker neodymium types with N35 magnets, stronger neodymium types with N52 magnets) and in both heavy and light variants so that they could be modified exactly according to the customers´ individual requirements.

Design of the hump magnet separator

The SOLLAU magnetic plate separator is equipped with an extraction plate, from which the captured metal impurities can be removed very easily. The magnetic part of the hump separator is released manually and moved away from the extraction plate. The captured impurities then fall off spontaneously. This magnetic chute is provided with a special projection on the surface of the extraction plate ensuring maximum separation efficiency and preventing the captured impurities in being washed away by the material flow which would result in quality degradation of the cleaned product.

Customer care

Your project will be taken care of by us from beginning up to the very end. It does not end with the order placed at us. We will provide the full support for all the time of the use of the separator.

1. We will come

2. We will align and design

3. We will make a made-to-measure product

4. We will install

5. We will put into operation and school in

6. We will provide authorized service

We guarantee tests withing three days!

Make sure that our device perfectly meets your expectations!

We will provide tests of your material on our magnetic separators for FREE!

What pipeline is the magnetic chute connected to?

The MS hump magnet is produced either in a version with housing (i.e. it is delivered with a part of the pipeline concluded with flanges for the connection to the existing customer's pipeline) or in a configuration without housing i. e. only a chute magnet is supplied in order to be incorporated by the customer into his pipeline system.

SOLLAU – our products are welded by real professionals!

SOLLAU certifications:

Authorization to perform welding on pressure equipment according to PED 2014 / 68 / EU

Pressure welder certificate according to EN-ISO 3834 - 2, EN 1090 - 2, EN 13480 - 1 to 5, EN 13445 - 1 to 5

The neodymium versions are very strong and they are used for separation of fine ferromagnetic particles (as for example metal splinters, wear from the pipeline, iron scales, pieces of machined stainless steel, etc.) even from a higher material layer (the neodymium magnets can capture particles from the size of 60 micrometers, but they are also capable of removing bigger ferromagnetic particles).

| Product | Dimension of input/output (mm) | Datasheet |

|---|---|---|

| MS-MC 250 N | 250 x 250 | display PDF |

| MS-MC 300 N | 300 x 350 | display PDF |

| MS-MC 350 N | 350 x 350 | display PDF |

| MS-MC 400 N | 400 x 350 | display PDF |

| MS-MC 450 N | 450 x 350 | display PDF |

| MS-MC 500 N | 500 x 350 | display PDF |

| MS-MC 600 N | 600 x 350 | display PDF |

Which industrial branches can the magnetic chute be used in?

The hump magnet finds its application in the food processing industry, fodder production, pharmaceutical industry, wood processing, chemical and ceramic industries etc.