Advantages of Eddy Current Separators from SOLLAU

Efficiency

They can remove up to 99% of non-magnetic metals from waste.

Fast delivery

We supply Eddy Current Separators with a delivery time of 8 weeks.

Warranty and service

3-year warranty and next working day service intervention.

Wide usage

Ideal for sorting waste, metals, and recycled materials.

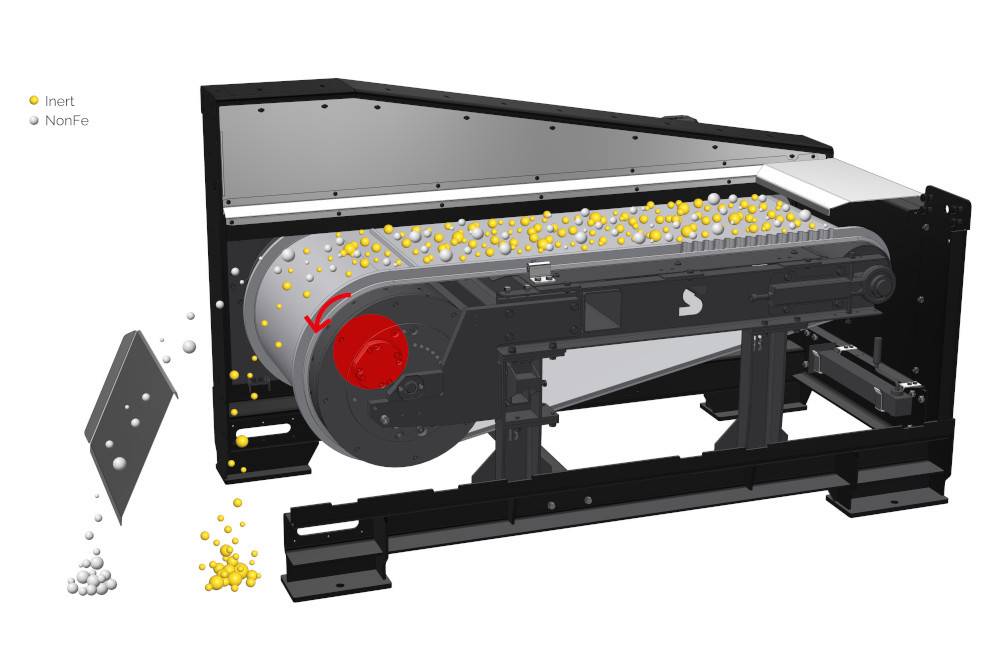

ECS separators can efficiently separate the separated material into two fractions:

- Non-magnetic metals (e.g. aluminum, copper, brass,...)

- Non-metallic materials (plastics, wood, glass,...)

The Eddy Current Separator (ECS) is used to separate non-magnetic metals from non-metallic materials. This magnetic separator for non-magnetic metals is based on the principle of so-called eddy currents which are induced by a magnetic roller embedded in the conveyor.

The magnetic roller (separator rotor) which is rotating at high speed (the magnetic poles are rapidly alternating) creates a magnetic field that magnetizes even non-ferromagnetic metallic materials for a short time. The magnetic polarity of the magnetized particles is the same as the polarity of the magnetic field generated by the separator rotor. Therefore, magnetized materials are repelled and automatically ejected from the conveyor belt.

EDDY CURRENT SEPARATOR ECS-E BULL, ECS-E BUFFALO:

3-YEAR WARRANTY & 3 FREE SERVICE INSPECTIONS

We will test your material within 3 days – free of charge

Three types of Eddy Current Separators

Separators with the centrically embedded rotor

(ECS-C RAM)

- Separation of metal particles in size from 50 mm

- Centrically embedded rotor

- Working width of 500 to 2,000 mm

- Attractive price

Separators with the eccentrically embedded rotor

(ECS-E BULL)

- Separation of metal particles in size from 1 mm

- Eccentrically embedded rotor

- Separation efficiency > 99 %

- Fast belt change - within 6 minutes

- Setting the rotor position while the separator is running

- 3-year warranty

- 3 free service inspections

- Working width 500 to 2,000 mm

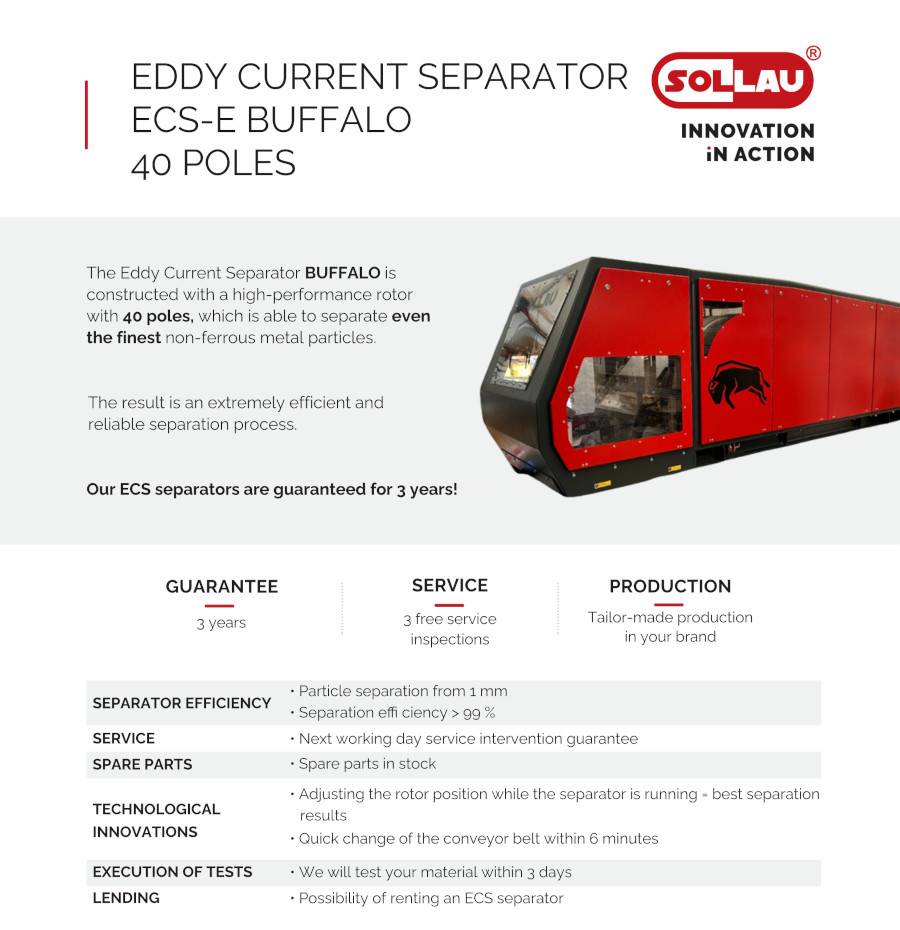

Separators with eccentrically embedded rotor

(ECS-E BUFFALO)

- Separation of very small particles from 0.5 mm

- 40 poles

- Eccentrically embedded rotor

- Separation efficiency > 99 %

- 3-year warranty

- 3 free service inspections

- Setting the rotor position while the separator is running

- Working width 500 to 1,500 mm

Take a look at how we test the effectiveness of our eddy current separators on aluminum and brass samples

How does cooperation work?

1.We will come

2.We will measure and design

3.We will manufacture to measure

4.We will install

5.We will commission and train

6.We will provide authorized service

Case studies on the use of the eddy current separator

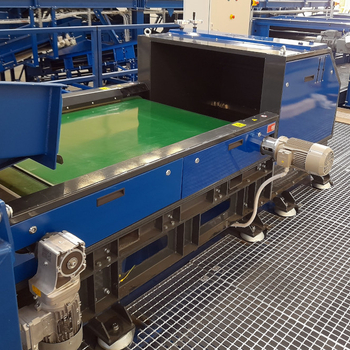

Photo gallery from projects

Videos from projects

Technical documentation to download

ECS-C RAM datasheets for download

| Product | Working width (mm) | Datasheet |

|---|---|---|

| ECS-C 500 RAM | 500 | display PDF |

| ECS-C 600 RAM | 600 | display PDF |

| ECS-C 800 RAM | 800 | display PDF |

| ECS-C 1000 RAM | 1000 | display PDF |

| ECS-C 1200 RAM | 1200 | display PDF |

| ECS-C 1500 RAM | 1500 | display PDF |

ECS-E BULL datasheets for download

| Product | Working width (mm) | Datasheet |

|---|---|---|

| ECS-E 500 BULL | 500 | display PDF |

| ECS-E 600 BULL | 600 | display PDF |

| ECS-E 800 BULL | 800 | display PDF |

| ECS-E 1000 BULL | 1000 | display PDF |

| ECS-E 1200 BULL | 1200 | display PDF |

| ECS-E 1500 BULL | 1500 | display PDF |

| ECS-E 1800 BULL | 1800 | display PDF |

| ECS-E 2000 BULL | 2000 | display PDF |

ECS-E BUFFALO datasheets for download

| Product | Working width (mm) | Datasheet |

|---|---|---|

| ECS-E 500 BUFFALO | 500 | display PDF |

| ECS-E 600 BUFFALO | 600 | display PDF |

| ECS-E 800 BUFFALO | 800 | display PDF |

| ECS-E 1000 BUFFALO | 1000 | display PDF |

| ECS-E 1200 BUFFALO | 1200 | display PDF |

| ECS-E 1500 BUFFALO | 1500 | display PDF |

Why the ECS from SOLLAU?

Download PDF

(size 576 kB)

Why the ECS-E BUFFALO from SOLLAU?

Download PDF

(Size 453 kB)

3-year warranty + 3 free service inspections

Download PDF

(size 596 kB)

ECS-E BULL spare parts

Download PDF

(size 192 kB)

Switchboards for ECS

Download PDF

(size 490 kB)

Have a question?

Are you interested in the possibilities of using a non-ferrous metal separator?

Do you want to discuss modifications, tailoring, or price?

Email us and we will contact you within 24 hours.