Spiral conveyor

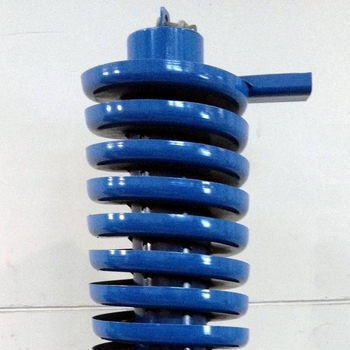

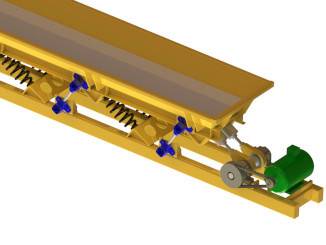

Spiral conveyors operate on the principle of micro-protrusions that gently propel material upwards using controlled vibration, eliminating direct mechanical contact.

This advanced technology ensures careful material handling. It reduces equipment wear, thereby extending its operational life and minimizing maintenance.

Spiral conveyors are the ideal solution for transporting sensitive or abrasive materials that require smooth and controlled movement.

They are ideal for operations where long equipment life and preservation of transported material quality are essential.

INDUSTRIES: Mineral raw materials, Connection accessories, Recycling

- No mechanical contact - material is transported by gentle vibrations, not rotating elements.

- Ideal for sensitive materials - no damage or particle sorting during transport.

- Low wear - the absence of frictional parts extends service life and reduces maintenance demand.

Comprehensive solutions from SOLLAU - magnetic separators, metal detectors, vibrating sieves, and vibrating feeders - all in one place!

KEY FEATURES AND ADVANTAGES OF THE SPIRAL CONVEYOR

- Gentle handling - spiral motion by vibrations minimizes mechanical stress and helps preserve the integrity of sensitive and abrasive materials.

- Maintenance-free design - no mechanical elements in the material path significantly reduce wear and service requirements.

- Flexibility of operation - the device is designed for different sizes, shapes, and weights of materials. It is ideal for a wide range of applications.

- Customization options - the conveyor can be optionally equipped with forced cooling, heating, or an airtight configuration to suit specific operating conditions.

WHERE IS THE SPIRAL CONVEYOR USED?

The spiral conveyor finds application in a broad spectrum of industry branches:

- Cement plants and building material production facilities

- Recycling

- Glass production

- Production of connection accessories

Customization options

The equipment can be supplemented with a forced cooling or heating system and supplied in an airtight design to prevent material leakage.

Photo gallery

Další vibrační dopravníky

The most common FAQ – Spiral conveyor

It uses micro-protrusions and controlled vibrations that propel the material upwards in a spiral path without direct mechanical contact.

The spiral conveyor is suitable for sensitive and abrasive materials that need to be protected from damage or sorting.

No. The design eliminates frictional contact, which extends conveyor life and maintains material quality.

Yes. Options such as forced cooling, heating, or airtight construction are available to meet specific production requirements.

The main advantage is the maintenance-free construction and minimal wear, as the material is not pushed mechanically.

It is applied in cement works, recycling, the glass industry, and fastener manufacturing.

How does cooperation work?

1.We will come

2.We will measure and design

3.We will manufacture to measure

4.We will install

5.We will commission and train

6.We will provide authorized service

Have a question?

Are you interested in the possibilities of using a vibrating conveyor?

Do you want to discuss modifications, tailoring, or price?

Email us and we will contact you within 24 hours.