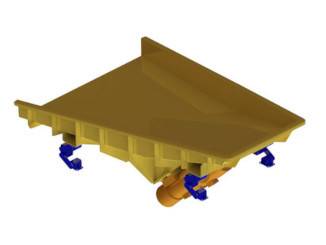

Heavy-Duty feeder

Heavy-duty feeders ensure uniform, controlled, and reliable dosing of bulk materials in highly demanding conditions and large volumes.

Its robust design and optimized vibration systems make it the ideal solution for feeding under large containers in the mining, metallurgical, and recycling industries.

INDUSTRY: Mineral raw materials, Recycling

- High capacity - more than 2,000 t/h, higher on request. They are ideal for high-capacity operations.

- Heavy-duty design - robust construction with long lifetime, low maintenance, and resistance to wear and impact.

- Continuous feed control - power adjustment from 25% to 100% via a frequency converter.

- Size - in 2 lengths (up to 6.3 m!) and 9 widths as standard.

Comprehensive solutions from SOLLAU - magnetic separators, metal detectors, vibrating sieves, and vibrating feeders - all in one place!

Need help choosing? We will be happy to recommend a solution tailored to your operation.

KEY FEATURES AND ADVANTAGES OF THE HEAVY-DUTY FEEDER

- High capacity - it can process more than 2,000 t/h. Upon request, we can also manufacture equipment for higher capacity. It is suitable for high-capacity operations.

- Heavy-duty design - robust construction with long service life, low maintenance requirements, and impact resistance.

- Size - vibrating feeder is available in 2 lengths (up to 6.3 m!) and 9 widths as standard

- Smooth feed rate control – the vibrating feeder allows speed regulation with fixed or variable adjustment using a frequency converter (adjustable within the range of 25% to 100% of the preset capacity).

- Variable design - open, closed, or dust-tight option to meet stringent environmental requirements.

- Tailored solution - optional inserts, weighing systems, closing gates, sensors, and automation.

WHERE IS THE HEAVY-DUTY FEEDER USED?

Vibratory heavy-duty feeders are used in a wide range of industry branches:

- Quarrying of aggregates, sand, and gravel

- Cement plants and building material production facilities

- Recycling

- Energetics

- Production of building materials

Customization options

The device can be equipped with optional elements, such as exchangeable inserts, regulatory gates, weighing systems, intelligent control units and advanced sensors. All this is for maximum customization to specific operating conditions.

Photo gallery

Need help choosing? We will be happy to recommend a solution tailored to your operation.

Other vibrating feeders

The most common FAQ – Heavy-Duty feeder

The standard capacity exceeds 2,000 t/h, however, the plant can be modified for higher volumes upon request.

It is a highly durable construction, suitable for abrasive materials and demanding operations, with minimal maintenance and long service life.

Yes. The feeder is specifically designed for installation beneath high-capacity containers and is capable of handling high pressure and heavy loads.

It is done using a frequency converter that enables smooth and adjustable power control, ranging from 25 % to 100 %.

Yes. We offer open, closed, and dust-tight versions that meet strict environmental and safety requirements.

It is most commonly used in mining, recycling, cement works, energetics, and in the production of building materials.

How does cooperation work?

1.We will come

2.We will measure and design

3.We will manufacture to measure

4.We will install

5.We will commission and train

6.We will provide authorized service

Have a question?

Are you interested in using SKAKO vibratory feeders?

Would you like to discuss modifications, customizations, or pricing?

Write to us and we will get back to you within 24 hours.