Dry high intensity magnetic separators LSV

The high gradient magnetic separator LSV equipped with an extra strong magnetic roll, is a scaled-down (but fully operational) version of the high intensity magnetic separator VMSV. It is used for a continuous and automatic separation also of very small (even c.30 µm) and weakly magnetic particles (e.g. magnetic stainless steel or also some kinds of paramagnetic minerals) in laboratory conditions.

Design of the laboratory magnetic separator LSV

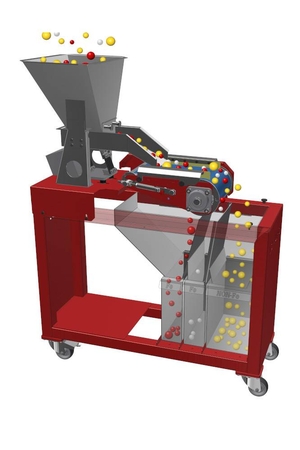

This extraordinarily powerful as well as compact and modular high gradient magnetic separator consists of a vibratory feeder and a pair of pulleys. The drive pulley is high intensity rare earth roll (with a rotational speed control according to the character of cleaned material and working needs) and the driven one is non-magnetic. Both pulleys are mutually connected to each other with a very thin, but extremely sturdy conveyor belt from kevlar or glass-teflon (available also in a non-sticky version). The magnetic field of the magnetic roller reaches the height of maximally c. 10 mm, and therefore the height of the material transported on the conveyor belt should not exceed 5 mm (and we recommend the max. height of 2 mm in order to achieve the highest efficiency).

How does the high intensity rare earth roll magnetic separator work?

After loosening the material by means of a vibrating feeder, the material falls down on the conveyor belt. Ferrous particles are caught up through the magnetic field of the roller and brought behind its axis into the container for ferromagnetic contaminants. The purified material (i.e. non-magnetic particles) will fall off by the instrumentality of gravitation into the container for the pure product - situated under the driving roller. Thanks to a special flow divider of the magnetic and non-magnetic material (angularly and axially adjustable) it is also possible to separate even the third fraction from the pure material. The third kind of the material can be found between the pure material and the ferromagnetic contaminants (thus it involves the lightly magnetic material, i. e., partly contaminated with iron particles). The separative process can be repeated as often as needed, because both the pure material and partly contaminated material and also the separated ferromagnetic particles are stored in independent containers under the conveyor belt (let us bear in mind, that the LSV, as an extremely strong magnetic separator, is able to catch also pieces of plastic, rubber, stones or wood slightly contaminated with e. g. iron oxides. That is why, its role is irreplaceable when doing laboratory testing and evaluating the processed materials.).

The vibratory feeder with an integrated filling hopper is the inseparable part of this special magnetic separator. The dimensions of the filling hopper accurately correspond with the conveyor belt width and the needed material dosing can be preset by means of a vibration regulator. The high intensity magnetic separator LSV is equipped with an appliance for a simple set up of the optimum conveyor belt tensioning and the drive roller motor is provided with a variable speed unit, which enables regulating the conveyor belt speed when required.

The rare earth roll separator LSV is determined for the most demanding customers, requiring the separation even of the finest ferromagnetic particles. In case of using extremely thin conveyor belts (e. g. from kevlar or glass-teflon), the maximum particles’ size coming into contact with this separator, should not exceed 5 mm. Bigger particles could namely damage the conveyor belts very fast (when processing bigger fractions of metal contaminants and/or the material itself, thicker conveyor belts can be used, however, their application will lead to the diminution of magnetic efficiency of this special separator).

Advantages of laboratory magnetic separator

Thanks to the material quality used, when producing the magnetic roller (combination of extra strong NdFeB magnets with special steel washers and the very thin but highly sturdy kevlar or glass-teflon conveyor belt) this high intensity separator is able to achieve a surface magnetic induction up to 21,000 gauss. This is a value, which has been reached so far only by electromagnetic separators. On the other hand, let us bear in mind that the reached value of the magnetic induction of the magnetic roller is not so important as the density of the magnetic poles, because the LSV is often used for catching small ferromagnetic particles. Should the distances between the magnetic poles be too large (in order to achieve the maximum magnetic induction), the very strong magnetic field generated in this way will not be exploitable for catching tiny impurities – because these would slip through due to big distances between the magnetic poles. Therefore, in combination with the very dense poling the optimum value of the magnetic induction on the roller surface ranges about 11,000 gauss to achieve the maximum capture also of very small ferromagnetic particles.

SOLLAU – our products are welded by real professionals!

SOLLAU certifications:

Authorization to perform welding on pressure equipment according to PED 2014 / 68 / EU

Pressure welder certificate according to EN-ISO 3834 - 2, EN 1090 - 2, EN 13480 - 1 to 5, EN 13445 - 1 to 5

LSV

- Automatic belt tensioner

- Wide range of conveyor belts

- Mobile version (on wheels)

- Up to three types of materials can be separated: non-magnetic, weakly magnetic, magnetic

- Application: e. g. in the area of material testing

The laboratory highly magnetic separator, equipped with an extra strong magnetic roll, is a scaled-down (but fully operational) version of the permanent multi-stage magnetic separator VMSV.

| Product | Datasheet |

|---|---|

| LSV | display PDF |

Some products from this model family are available for immediate purchase. We are constantly extending the offer of our magnetic separators in stock so that we can deliver them to you immediately. Please, contact our dealer to inform for their current availability.

Which industrial branches can the dry high intensity separator be used in?

The laboratory variant of DHIMS finds its use in the food-processing industry (especially for material testing or final cleaning of meat and bone meal or salt from salt mines), in pharmaceutics, at e-scrap recycling (e.g. for removing undesirable slightly magnetic stainless particles), in the foundry industry (for purification of various sorts of foundry sand), in the glass and ceramic industry (for separation of undesirable magnetic particles from silica and various sorts of glass sand, china clay, limestone, clay).