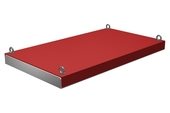

Suspended magnets DND-MC

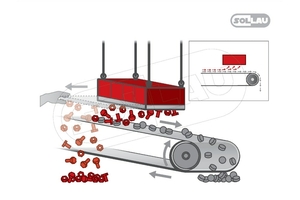

Suspended permanent magnet with manual cleaning is the simplest and cheapest equipment for the separation of ferromagnetic particles from materials transported on a belt conveyor. This permanent magnetic separator is suitable for materials with lower content of magnetic metal particles (if the cleaning is not required more often than once a work shift).

How is the suspension magnet cleaned?

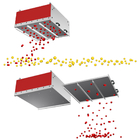

The magnetic plate is suspended above the belt conveyor and the magnetic impurities are captured at the bottom of the magnetic plate (usually fitted with strong permanent ferrite magnets, however on client's requirement is is possible to use extremely strong neodymium NdFeB magnets). The ferrous particles accumulated on the surface of the magnetic plate are removed manually. If the material contains too many ferromagnetic particles, the magnetic plate is swiftly clogged with ferrous particles. In this case we recommend that the clients opt for our overband magnetic separator DND-AC with automatic cleaning.

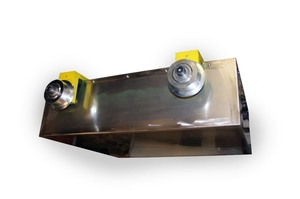

Easy cleaning suspended magnet DND-MC

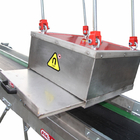

DND-MC magnetic plate can be equipped (at extra charge) with a cleaning stripper tray for simple removal of the trapped magnetic particles. On the bottom of the cleaning stripper tray (that protects the magnetic core steel plate) there are longitudinal steel slats that prevent the captured ferromagnetic particles from jumping onto the magnetic core steel plate during the cleaning (when the cleaning stripper tray is being drawn out) and also ensure uniform distribution of the trapped ferrous material on the stripper tray surface.

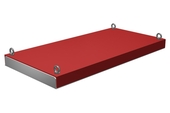

Dimensions of the permanent suspension magnet

The magnetic plate with manual cleaning can be made in any size according to customer's needs.

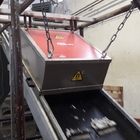

Suspended magnet on a rail construction

Manual cleaning permanent magnetic separator on a special rail construction is a sophisticated version of the suspended magnet. Thanks to the rail construction it is possible to move the magnetic plate aside and carry out the cleaning or maintenance in a very easy and safe way even without stoppage of the conveyor belt.

Manual cleaning permanent magnetic separator on a special rail construction is a sophisticated version of the suspended magnet. Thanks to the rail construction it is possible to move the magnetic plate aside and carry out the cleaning or maintenance in a very easy and safe way even without stoppage of the conveyor belt.

Combination of a suspension magnet with a magnetic pulley

In order to achieve the most efficient iron tramp separation in case of a high layer of the transported material, we recommend to combine the use of the magnetic plate with our magnetic pulley MV that can separate the ferromagnetic particles also from lower layers of the transported material.

We guarantee tests withing three days!

Make sure that our device perfectly meets your expectations!

We will provide tests of your material on our magnetic separators for FREE!

In total there are eight types of SOLLAU suspended magnets (five ferrite and three neodymium ones, see below), so that even standard products can satisfy the needs and requirements of the broadest possible spectrum of clients. At the same time, our customers can be sure that the parameters of the product are in accordance with their needs and that they will not pay extra money for an above standard equipment that would be unnecessary for their specific application.

SOLLAU – our products are welded by real professionals!

SOLLAU certifications:

Authorization to perform welding on pressure equipment according to PED 2014 / 68 / EU

Pressure welder certificate according to EN-ISO 3834 - 2, EN 1090 - 2, EN 13480 - 1 to 5, EN 13445 - 1 to 5

Ferrite suspension magnets

The main benefits of ferrite magnetic plates include the following: high temperature resistance, long-term magnetic stability, affordable price, deep and very strong magnetic field (in case of stronger models).

- Installation height up to 200 mm

- Lower weight

- Capturing ferromagnetic particles bigger than 1 mm

Combines a standard performance with an interesting price. These separators are intended for medium-duty applications with the maximum installation height of 200 mm, and they are capable of trapping larger ferromagnetic particles (above 1 mm). A very good rate of return (price/performance ratio) is a significant benefit of this kind of plate.

| Product | Maximum width of conveyor belt (mm) | Maximum recommended installation height (mm) | Datasheet | |

|---|---|---|---|---|

| crosswise | longwise | |||

| DND-MC M1 F | 500 | 650 | 170 | display PDF |

| DND-MC M2 F | 800 | 650 | 200 | display PDF |

| DND-MC M3 F | 1000 | 650 | 200 | display PDF |

| DND-MC M4 F | 1200 | 650 | 200 | display PDF |

| DND-MC M5 F | 1400 | 650 | 200 | display PDF |

| DND-MC M6 F | 1600 | 650 | 200 | display PDF |

| DND-MC M7 F | 1800 | 650 | 200 | display PDF |

Is intended for heavy-duty users who expect from the separator a high performance even at greater depths (the maximum installation height is 320 mm).

| Product | Maximum width of conveyor belt (mm) | Maximum recommended installation height (mm) | Datasheet | |

|---|---|---|---|---|

| crosswise | longwise | |||

| DND-MC Ms2 F | 800 | 850 | 270 | display PDF |

| DND-MC Ms3 F | 1000 | 850 | 300 | display PDF |

| DND-MC Ms4 F | 1200 | 850 | 320 | display PDF |

| DND-MC Ms5 F | 1400 | 850 | 320 | display PDF |

| DND-MC Ms6 F | 1600 | 850 | 320 | display PDF |

| DND-MC Ms7 F | 1800 | 850 | 320 | display PDF |

| DND-MC Ms8 F | 2000 | 850 | 320 | display PDF |

- Installation height up to 340 mm

- Larger width version specially designed for applications above the overflow

- Capturing ferromagnetic particles bigger than 1 mm

Is a model intended for the installation height up to 340 mm (it is also wider, what is its another advantage).

| Product | Maximum width of conveyor belt (mm) | Maximum recommended installation height (mm) | Datasheet | |

|---|---|---|---|---|

| crosswise | longwise | |||

| DND-MC Mp2 F | 800 | 1050 | 290 | display PDF |

| DND-MC Mp3 F | 1000 | 1050 | 320 | display PDF |

| DND-MC Mp4 F | 1200 | 1050 | 340 | display PDF |

| DND-MC Mp5 F | 1400 | 1050 | 340 | display PDF |

| DND-MC Mp6 F | 1600 | 1050 | 340 | display PDF |

| DND-MC Mp7 F | 1800 | 1050 | 340 | display PDF |

| DND-MC Mp8 F | 2000 | 1050 | 340 | display PDF |

Is designated for very demanding applications and for removal of ferromagnetic particles from depths of up to 400 mm.

| Product | Maximum width of conveyor belt (mm) | Maximum recommended installation height (mm) | Datasheet | |

|---|---|---|---|---|

| crosswise | longwise | |||

| DND-MC Mm2 F | 800 | 1200 | 320 | display PDF |

| DND-MC Mm3 F | 1000 | 1200 | 350 | display PDF |

| DND-MC Mm4 F | 1200 | 1200 | 400 | display PDF |

| DND-MC Mm5 F | 1400 | 1200 | 400 | display PDF |

| DND-MC Mm6 F | 1600 | 1200 | 400 | display PDF |

| DND-MC Mm7 F | 1800 | 1200 | 400 | display PDF |

| DND-MC Mm8 F | 2000 | 1200 | 400 | display PDF |

Is the strongest of all SOLLAU magnetic plates. Magnetic induction of these devices is at the limit of the capabilities of the strongest permanent magnets and can only be surpassed by electromagnetic separators. This series is intended for the most challenging separation from extreme depths and high and heavy material layers. The maximum suspension height of these devices is 450 mm (an interesting fact: the strongest ferrite DND-MC Mx F series is approximately five times heavier than the lightest DND-MC M F series!).

| Product | Maximum width of conveyor belt (mm) | Maximum recommended installation height (mm) | Datasheet | |

|---|---|---|---|---|

| crosswise | longwise | |||

| DND-MC Mx3 F | 1000 | 1450 | 450 | display PDF |

| DND-MC Mx4 F | 1200 | 1450 | 450 | display PDF |

| DND-MC Mx5 F | 1400 | 1450 | 450 | display PDF |

| DND-MC Mx6 F | 1600 | 1450 | 450 | display PDF |

| DND-MC Mx7 F | 1800 | 1450 | 450 | display PDF |

| DND-MC Mx8 F | 2000 | 1450 | 450 | display PDF |

Neodymium suspension magnets

An extremely strong (but relatively short) magnetic field and a low weight are the most significant benefits of neodymium suspension magnets. That is why the application of the neodymium plates is preferred at the places where it would not be possible to use heavy ferrite plates or where a very high separation efficiency at shallower depths is required (e. g., in cases of mobile crushing and recycling lines).

Is the lightest series intended for the maximum suspension height of 200 mm. This plate is even able to trap Fe particles smaller than 1 mm (at shallower depths).

| Product | Maximum width of conveyor belt (mm) At crosswise installation above the conveyor | Maximum recommended installation height (mm) | Datasheet |

|---|---|---|---|

| DND-MC N1 | 500 | 200 | display PDF |

| DND-MC N2 | 800 | 200 | display PDF |

| DND-MC N3 | 1000 | 200 | display PDF |

| DND-MC N4 | 1200 | 200 | display PDF |

| DND-MC N5 | 1400 | 200 | display PDF |

| DND-MC N6 | 1600 | 200 | display PDF |

| DND-MC N7 | 1800 | 200 | display PDF |

is a stronger neodymium variant (with a maximum installation height of 220 mm), intended for medium-duty applications. Its benefits include: a high magnetic induction (at a short distance), a separation of smaller Fe particles and a low weight.

| Product* | Maximum width of conveyor belt (mm) At crosswise installation above the conveyor | Maximum recommended installation height (mm) | Datasheet |

|---|---|---|---|

| DND-MC Ns1 | 500 | 220 | display PDF |

| DND-MC Ns2 | 800 | 220 | display PDF |

| DND-MC Ns3 | 1000 | 220 | display PDF |

| DND-MC Ns4 | 1200 | 220 | display PDF |

| DND-MC Ns5 | 1400 | 220 | display PDF |

| DND-MC Ns6 | 1600 | 220 | display PDF |

| DND-MC Ns7 | 1800 | 220 | display PDF |

This is the strongest neodymium model, particularly intended for mobile applications where an extremely high magnetic induction at shallower material depths is needed. Maximum installation height: 250 mm.

| Product | Maximum width of conveyor belt (mm) At crosswise installation above the conveyor | Maximum recommended installation height (mm) | Datasheet |

|---|---|---|---|

| DND-MC Nm1 | 500 | 300 | display PDF |

| DND-MC Nm2 | 800 | 300 | display PDF |

| DND-MC Nm3 | 1000 | 300 | display PDF |

| DND-MC Nm4 | 1200 | 300 | display PDF |

| DND-MC Nm5 | 1400 | 300 | display PDF |

| DND-MC Nm6 | 1600 | 300 | display PDF |

| DND-MC Nm7 | 1800 | 300 | display PDF |

Which industrial branches can the suspended magnets be used in?

This manual cleaning permanent magnetic separator finds use in recycling, mining, plastic, glass and wood industries.