23. 8. 2022

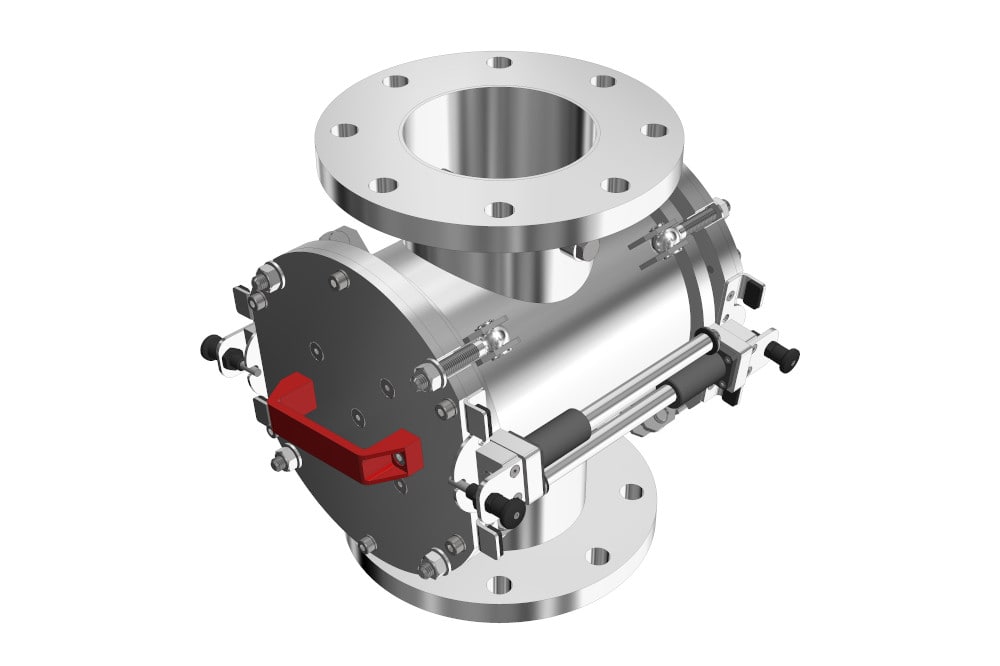

ML-P plate magnetic separator for pipelines

The ML-P trap magnet in the plate design is intended especially for the separation of ferromagnetic particles from problematic, which could damage or block standard types of magnetic separators, e. g. grate separators. Therefore, it is mainly used in pressure or vacuum pipeline systems, which are characterized by a relatively high operating capacity and serve to transport material that tend to bridge (e.g. cellulose solution with long plant fibers).

The main advantages of the ML-P pipe plate magnet

- High efficiency thanks to the application of neodymium magnets (up to 7500 G)

- Detachable baffle (= directing the material flow toward the magnetic field)

- Tapered step face (= active magnetic protrusion in the middle of the plate magnet prevents already captured Fe particles from being wiped off by the flowing material)

- High capacity (up to 150 m3 / h)

- Plate magnets on slides (= easy, quick and safe cleaning)

- Universality of application (separation of small particles as well as larger iron objects)