1. 2. 2024

Safe separation of steel sheets with a magnetic sheet separator (case study)

Initial status

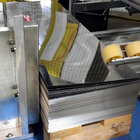

Our customer processes 0,3 – 0,8 mm steel sheets. The sheets are stacked - the height of the sheet stack is 300 mm. Sheets of 400 x 800 mm are most often processed.

Problem

In a fully automated operation, the customer needs to handle thin sheets. A vacuum manipulator is used for gripping and lifting steel sheets. The manipulator grips only one sheet, as required by the customer.

These thin sheets tend to "stick" to each other and are very difficult to separate.

The sheets have a polished surface and must not be scratched. So it is impossible to separate the sheets manually. In addition, the customer requires an unattended operation so that the production line can be fully automated.

Solution

For the separation of stacked sheets, we recommended the customer to use the magnetic sheet separator MC-F 330. As the sheets are lifted by a vacuum manipulator, it is sufficient for the individual steel sheets to be separated from each other in only one place (it is not necessary to fan e. g. one whole side of the stack, what is common if the sheets are lifted manually).

That was why we placed the magnetic sheet separator in one corner of the sheet stack only. It came to a partial steel sheet separation on two sides, which was sufficient for the vacuum manipulator to lift the sheet.

We chose a magnetic sheet fanner with a height of 330 mm (as the stack maximum height was of only 300 mm).

Benefits of using the magnetic sheet separator MC-F 330

We have made it possible for even very thin sheets to be handled by a vacuum manipulator. The sheets were separated from each other so that only one sheet could be lifted. Therefore, the polished sheets would not get scratched. Thanks to the use of the magnetic sheet separator the production line could be fully automated.

- Quality: No scratches on polished sheet metals

- Easy handling: The magnetic sheet separator MC-F 330made it easy to separate and manipulate sheets without the need for physical intervention by employees

- Enhanced security: By eliminating the manual handling of the steel sheets, the risk of workplace accidents was reduced and the safety of the working environment was improved

- Increased efficiency: The use of the magnetic sheet separator increased the work efficiency and reduced the time for sheet metal handling

- Cost reduction: By automating the process of metal sheets handling, the company saved on labor and increased its efficiency

Applied equipment: Magnetic sheet fanner MC-F 330

Advantages of the MC magnetic separator

- Robust design of the magnetic separator

- Separation of sheets up to 3 mm thick

- Modular system (different types of clarifiers can be mounted on one bracket base)

- Tailor-made production

- Hire of the plate changer

- Selected models permanently in stock