Sorting line for separation of ferromagnetic adulterants coming from magnezite (garnet) sand

Compound of the line

Case study

Principal types of challenges

- unique properties of the magnezite (thus garnet) sand make it to be raw material with an extraordinerily wide spectrum of applications (in food processing industry, pharmaceutical industry, agriculture, but also e. g. in nuclear energetics). The processor has appealed to SOLLAU s.r.o. with a requirement of removing the undesirable adulterants (being of fraction of 2 mm maximum), but whereas it was essential to separate not only the fine ferromagnetic particles (especially the scraps and abrasion of the devices used at crushing garnet sand) but also non-magnetic adulterants (earth, wood etc.)

- high processing capacity (up to 5 tons/hour)

- continuous (uninterupted) production process required the application of separators with automatic cleaning

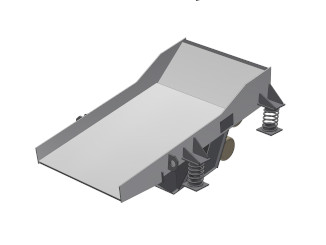

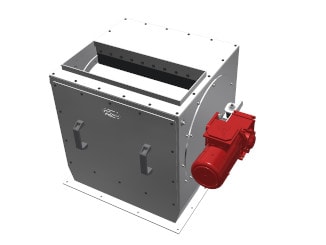

Solution provided by SOLLAU s.r.o. company: a compact assorting line that has solved the problem in two stages has been delivered. As first the material is dosed uniformly by a vibrating feeder on MBZ neodym covered drum separating all undesirable strongly magnetic adulterants (bits and scrapping of machinery). In stage two the cleaning process is based on the fact that garnat sand itself is very weakly magnetic (or even paramagnetic). Consequently during this stage the material free from ferromagnetic particles goes through extremely strong magnetic field (up to 11,000 G) of VMSV roller poled radially catching the weakly magnetic particles of garnat sand and carrying them away even behind the axis of the roller to be processed further. Non-magnetic material (scraps of wood, earth etc.) falls off spontaneously by the effect of gravitation at the end of the belt into a discharging manifold. The client was satisfied both with the high effectiveness of the delivered solution and with the relative simplicity of the delivered technology removing magnetic and non-magnetic contaminants out of the final material on a relatively small area.

SOLLAU – our products are welded by real professionals!

SOLLAU certifications:

Authorization to perform welding on pressure equipment according to PED 2014 / 68 / EU

Pressure welder certificate according to EN-ISO 3834 - 2, EN 1090 - 2, EN 13480 - 1 to 5, EN 13445 - 1 to 5