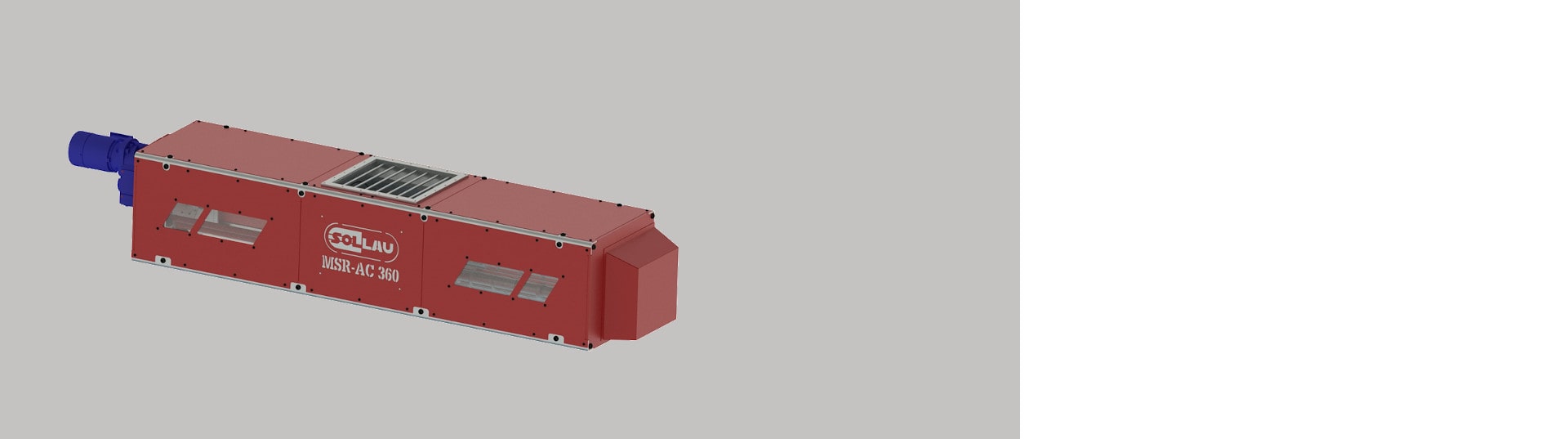

Telescopic rotational magnetic separators MSR-AC

Rotatory magnetic separator with automatic cleaning is determined to separation of fine ferromagnetic particles from a free falling (even worse permeable) material and it preserves against the damage of the machine and appliance processing the cleaned material subsequently.

Benefits for the use of separator

- Material free of ferromagnetic adulterants

- Permanent preservation of the technological appliance

- Fluent production operation

Customer care

Your project will be taken care of by us from beginning up to the very end. It does not end with the order placed at us. We will provide the full support for all the time of the use of the separator.

1. We will come

2. We will align and design

3. We will make a made-to-measure product

4. We will install

5. We will put into operation and school in

6. We will provide authorized service

We guarantee tests withing three days!

Make sure that our device perfectly meets your expectations!

We will provide tests of your material on our magnetic separators for FREE!

Magnetic rotary separator with the system of automatic cleaning enables easy, highly efficient and quick segregation of even the finest magnetic metal impurities (in the size from 1 µm) out of discrete materials and preserves against the damage of the machine and appliance processing already cleaned material. MSR-AC is capable of separating even weakly magnetic stainless steel and it even manages to process even the worse permeable or more abrasive materials that would block or harm a common magnetic separator with static grates. The magnetic tubes positioned inside the separator are cleaned automatically alternately which gives sthe guarantee of both continuous separation of ferromagnetic particles and continual production running.

Principle advantages of MSR-AC rotary separator with automatic cleaning

- as one of the few manufacturers of magnetic separators in the whole world we produce the rotary magnetic separator even for plants that the operation cannot (e.g. due to the technological reasons) be interrupted in. So MSR-AC is capable of carrying out both self-cleaning and also magnetic separation

- very frequently this separator is used also in the plants that enable the interruption of the operation for purpose of cleaning the separator, nevertheless the separator can be positioned in an awkward point only, exclusing the possibility of its regular cleaning

- after setting the required intervals for cleaning (eventually further atributes) the device works completely independently and it excludes the risky human factor out of the process in this way

- thanks to the fact that the set of magnetic pipes is not static but its spindle is turned by the electromotor, the magnetic sieve created in this way is not only in a very intensive contact with the circumfluent material but the magnetic pipes are (in contradisction to classical fix magnetic grates) also uniformly all around the whole circumference exposed to the abrasive effect of the material falling through (which leads to the reduction of the risk of cutting through of the protective pipes made of stainless steel and extending their service life)

- further indisputable advantage of this separator is the fact that the material being cleaned falls through the rotating set of magnetic pipes (rotation speed can be set in the way to suit optimally the permeability of the material being cleaned), by which the risk of tamping of the separator is eliminated.

- rotary separator can be cleaned very easily and quickly because the impurities caught fall off out of the surface spontaneously out of the surface of the grate after pull-out of covering pipes out of magnetic cores

- neodym cores generate very strong magnetic field catching the ferromagnetic particles (including the impurities from the magnetized stainless steel) on the surface of covering stainless pipes

How is rotary automatic separator cleaned?

The intervals for cleaning of covering stainless pipes are configurable individually based the level of contamination of the product and the individual client´s needs. In order to achieve as effective separation of the magnetic particles as possible the automatic magnetic grate-shaped separator is bedded with strong neodym NdFeB magnets. Automatic cleaning of the magnetic separator is ensured by pneumatic elements and fully programmable indipendent control unit. The control panel in an indiscrete design and with an easily serviceable touch screen gives the guarantee of quick individual setting of the magnetic separator for the particular application. Automatic cleaning of the magnetic separator gives an option of installation in the fully automatized plants and at the same time it ensures also the high economization of the operation in this way.

During falling through of the material through the turning pipe type grate the magnetic metal impurities are caught on the surface of the outer covering stainless steel pipes thanks to the strong permanent magnets. The pipe type rotary grate covers two thirds of the width of the separator and simultaneously the magnetic cores go on occuring below the input for the contaminated material. So thanks to the two-third length of the covering pipes the magnetic cores are permanently protected by the covering stainless pipes, whereas a half of the length of the covering pipes (i. e. the part that exceeds into the zone of actual cleaning) gets rid of magnetic impurities constantly. This gives the guarantee of continuousness of both cleaning and also separation process (without a need of interrupting the production cycle in the course of magnetic separation).

The set of rotating covering pipes moves by air-operated drive e. g. to the right in the pre-configured intervals. The discharge of the impurities caught on the surface of the covering pipes into the waste damping hopper on the mentioned right side for the time of the interval for cleaning pre-configured by the client. After expiration of the interval for cleaning the covering pipes move to the left and the ferromagnetic impurities caught fall off into the ferrous tramp metal discharge for contaminants but this time on the left side. After ending the cleaning process the covering pipes of the magnetic cores move to the right again and the whole process repeats ciclically without a break.

The process of separation can be also monitored via an inspection window in the upper part of the separator. Due to the high demands of food industry and pharmaceutical industry some parts of the separator entering the contact with the material being cleaned can be delivered in the polished design.

Magnetic rotary separators with automatic cleaning and continual cleaning find the use at cleaning of worse permeable powder type materials (e. g. of the greasy ones) with a relatively high content of ferromagnetic particles in various sectors of industry.

SOLLAU – our products are welded by real professionals!

SOLLAU certifications:

Authorization to perform welding on pressure equipment according to PED 2014 / 68 / EU

Pressure welder certificate according to EN-ISO 3834 - 2, EN 1090 - 2, EN 13480 - 1 to 5, EN 13445 - 1 to 5

- Automatic cleaning without a need of interrupting the flow of material

- Equal abrasion of protective stainless grate

- Thick magnetic sieve

- Large intercepting magnetic area

- Inspection opening to inspect the course of separation

| Product | Maximum capacity (m3/h) | Dimension of input/output (mm) | Datasheet |

|---|---|---|---|

| MSR-AC 270 | 20 | 270x270 | display PDF |

| MSR-AC 360 | 35 | 360x360 | display PDF |

We produce magnetic separators in these three levels of magnetic induction

Which industrial branches can the rotational magnetic separator be use of in?

Magnetic rotating separators are mostly used in the area of recycling and waste treatment, food processing, pharmaceutics, wood processing, plastic industries, mining and mineral processing, industrial production of ceramics and glass etc.