10. 5. 2023

Chute magnet - sugar production (case stidy)

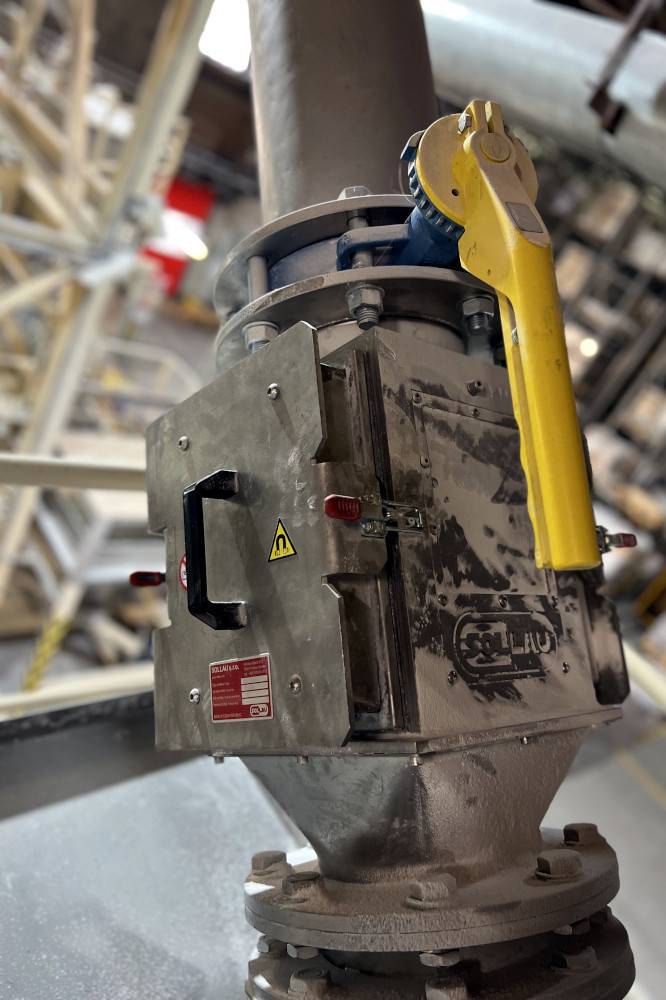

In this case study, we would like to show you a typical example of achute magnet application (also called a plate housing magnet or a round pipe separator).

Our separator fulfills its function in a sugar factorywhere it separates ferrous particles from granulated sugar. The sugar fraction is 0.6 mm.

The magnetic separator is installed in a 200-mm-diameter pipe, where some 25 to 30 tons of crystal sugar are processed per hour!

The customer was in need to separate even very fine ferrous particles(from 0.5 mm in size). For that reason, we chose the separator variant fitted with the strongest neodymium magnets. Thanks to them, the separator generates an extremely high magnetic strength of 7500 G and meets the customer's requirements, i. e., to separate ferrous particles in size from 0,5 mm. There is a manually operated flap at the inline separator entrance that can stop the material flow when the separator is to be cleaned.

It is typical for a sugar factory that the separation is carried out in several steps according to the size of the separated particles. At this stage of production, we separated ferrous particles larger than 0.5 mm. To achieve perfect separation, we installed the drawer magnet MSS-MC LUX at the final production stage. This separator is equipped with neodymium magnets generating a magnetic induction of up to 187 00 G, which allows the separation of ferromagnetic contaminants in size from 1 micron. The customer was absolutely satisfied with the magnetic solution provided by our company.

Each production stage requires a different type of magnetic separator. Our salesmen will help you find the most suitable separator for your application!

Applied equipment ML 200 N chute magnet