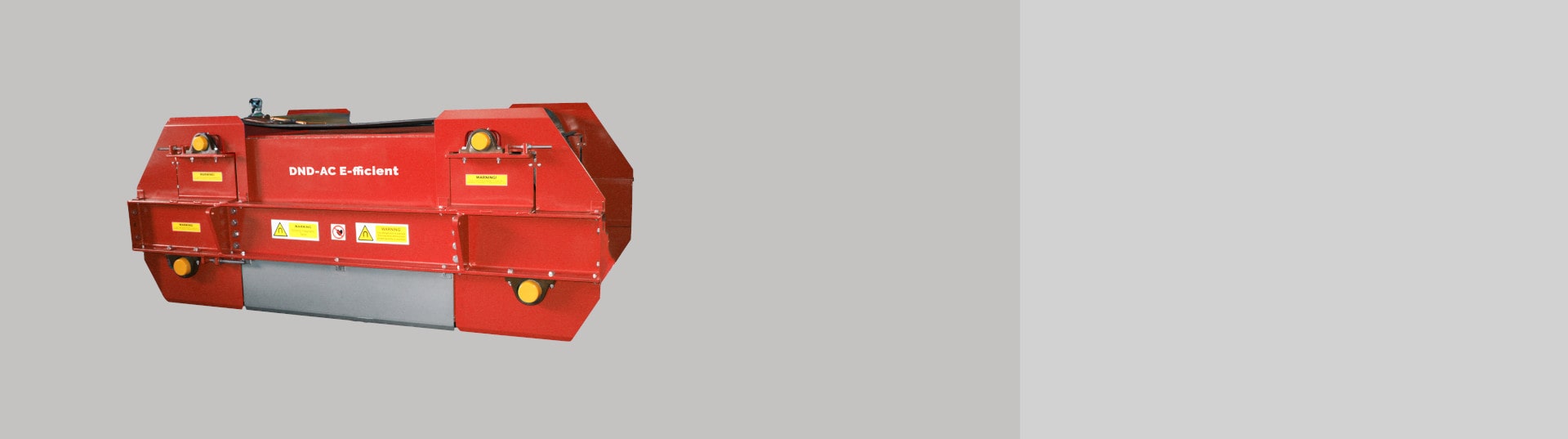

Electromagnetic overband DND-AC E

Overband magnet (or suspension magnet) sits above a conveyor carrying material. As the material passes under the magnet, ferrous metal is attracted up and out of the non-magnetic burden and transported by a heavy duty rubber belt into a skip or a collection bin at the side of the conveyor. The magnetic attractive force of an electromagnetic overband is stronger at distance with a higher magnetic gradient (attracting and extracting smaller ferrous metals) than a permanent design. That is why the electro overband magnets are preferable for the separation of tramp iron in the form of nuts, bolts and ferrous metal blasting caps and heavier pieces.

Besides, when there is a deep burden of conveyed material, high magnetic forces are needed to extract the ferrous metal from underneath the non-metallic material and the electro overbands are able to cope with this task. And for applications where the overband magnet requires switching off, the only option is the electro overband magnet, where the magnetic field is easily switched on and off.

Benefits for the use of separator

- Final material without iron contamination

- Protection of production equipment

- Smooth production operation

- Automatic cleaning without interruption of the material flow

- Elimination of operator errors

Comparison of electromagnetic suspension plates with automatic cleaning

| Crossbelt installation | Inline installation | ||||||

| DND-AC E-conomic |

DND-AC E-fficient |

DND-AC E-xtreme |

DND-AC E-conomic |

DND-AC E-fficient |

DND-AC E-xtreme |

||

| Customer belt | Min. width [mm] | 1000 | 500 | 500 | 500 | 500 | |

| Max. width [mm] | 1500 | 2000 | 2000 | 1000 | 2000 | 2000 | |

| Max. speed [m/s] | 2 | 5 | 5 | 2,5 | 4 | 4 | |

| Ferrous objects | Min. weight [kg] | 0,05 | 0,05 | 0,05 | 0,05 | 0,05 | 0,05 |

| Max. weight [kg] | 15 | 20 | 20 | 20 | 25 | 25 | |

| Min. size | M18nut / M16x16bolt | ||||||

| Max. size | not defined | ||||||

| Magnet Input Watts | Min. [kW] | 4,86 | 0,6 | 1 | 4,86 | 0,6 | 1 |

| Max. [kW] | 6,99 | 12 | 34 | 6,99 | 12 | 34 | |

| Machine weight | Min. [t] | 2,014 | 0,22 | 0,16 | 2,014 | 0,22 | 0,16 |

| Max. [t] | 2,821 | 8 | 29 | 2,821 | 8 | 29 | |

| Main supply | Standard [V] | 415-3-50 | |||||

| Optional [V] | as to customer requirement | ||||||

Separátor design

The basic design includes an electromagnetic unit mounted in a frame with two or four pulleys and a self-cleaning rubber belt.

Transformer rectifier

Transformer rectifier provides power to the magnet at the correct Amps, depending on magnet design, ambient temperature and input voltage.

Transformer rectifier design

- Fully welded steel enclosure to IP 65

- Oil level gauge fitted to front of tank (refers to oil cooled versions)

- Double wound transformer to BS EN 60076

- Rectifier according to BS 4417 ABCD

- Diode protection with fast acting semi-conductor fuses

- Ideal for mobile recycling equipment

- Highest magnetic power to weight ratio,

- Light

- Low profile

- Compact design

Parameters

- Budget version (attractive price/performance ratio)

- Main supply: 415 V (suitable also for 400 and 380 V supply modes)

- Magnet input: from 4,86 to 6,99 kW

- Max. customer belt speed: 2,5 m/s

- Some models permanently in stock

- Suspension height up to 450 mm

- Max. conveyor belt width: 1500 mm

- No oil present (air cooled system)

- Suspension height up to 1000 mm

- Main supply: 415 V (suitable also for 400 and 380 V supply modes)

- Magnet input: from 0,6 to 12 kW

- Max. customer belt speed: 5 m/s

- Max. conveyor belt width: 2000 mm (permanent magnetic extension possible to cover distances up to 3000 mm)

- No oil present (air cooled system)

- Suspension height up to 1000 mm

- Main supply: 415 V (suitable also for 400 and 380 V supply modes)

- Magnet input: from 1 to 34 kW

- Max. customer belt speed: 5 m/s

- Strongest electromagnetic overband

- Max. conveyor belt width: 2000 mm (permanent magnetic extension possible to cover distances up to 3000 mm)

- Oil cooled system

- Long life magnetic coil design

Which industrial branches can the electromagnetic overband be use of in?

Electromagnetic overbands offered by SOLLAU are made in co-operation with a renowned European producer in order to be used in difficult and arduous environments including mobile crushers, screens and shredders, MRF (Material Recovery Facility) and pre-sorted refuse plants, municipal solid waste plants, quarries, mining operations, bulk handling terminals, wood waste processing plants, fragmentiser plants for shredded vehicles, cullet (crushed glass) recycling plants, industrial skip waste recycling operations, foundries etc.