Multi-drum magnetic separators VMBZ

Double and triple magnetic drum / High gradient magnetic separator / Double and triple rotating drum magnet / Double and triple type magnetic separator

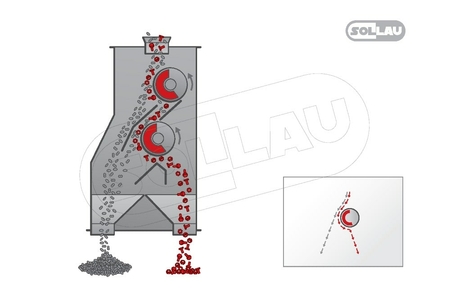

The multi-drum magnetic separator is a device for automatic and permanent removal of magnetic contaminants from loose mixtures. The magnetic system composed of several drums simplifies and speeds up the capture of undesirable ferromagnetic contaminants (including weak magnetic stainless steel), allows for automatic separation without production stoppage and assures the highest purity of the clean material. At the same time, the magnetic drum protects the following machinery (crushers, mills, etc.) processing the purified material from damage. The heart of the magnetic drum consists of magnetic cores (made from either ferrite or neodymium NdFeB magnets) in the shape of crescent around which the stainless steel drum rotates. The strong permanent magnets capture and drag the ferromagnetic impurities on the surface of the rotating drums. The ferrous pieces fall off beyond the magnetic axis of the upper drum, the purified material is poured onto the drum located below where the separation process is repeated in the same manner.

SOLLAU 5 year warranty

We can vouch for the quality of our magnetic separators and that is why why we provide a 5 year warranty on them! Our magnetic separators can be relied on! We are a specialist in the field of magnetic separation.

Installation of the multi stage magnetic drum

The double or triple drum magnetic separator can be placed at the output of a conveyor belt or below a hopper (unlike the magnetic pulley the magnetic drum is not an integral part of the conveyor). It is also possible to deliver the magnetic drum also in a stainless steel housing with two hoppers under the case. The non-magnetic materials fall into the first hopper, whereas the caught metal impurities are transported on the surface of the drum and fall off beyond the magnetic axis of the drum into the second hopper.

SOLLAU – our products are welded by real professionals!

SOLLAU certifications:

Authorization to perform welding on pressure equipment according to PED 2014 / 68 / EU

Pressure welder certificate according to EN-ISO 3834 - 2, EN 1090 - 2, EN 13480 - 1 to 5, EN 13445 - 1 to 5

VMBZ

- Double or triple magnetic drums

- Adjustable material spreader (to regulate the material input)

- Integrated wiper blades remove fine or sticky dust from the drum surface

- Quick and easy adjustment of the magnetic core position

- Sophisticated design with various inspection and service openings

The multi-drum magnetic separator is a device for automatic and permanent removal of magnetic contaminants from loose mixtures. The magnetic system composed of several drums simplifies and speeds up the capture of undesirable ferromagnetic contaminants (including weak magnetic stainless steel), allows for automatic separation without production stoppage and assures the highest purity of the clean material.

| Product | Dimension of input/output (mm) | Datasheet |

|---|---|---|

| TMBZ 254 F 500 | 520 x 550 | display PDF |

| TMBZ 254 F 1000 | 1020 x 550 | display PDF |

Which industrial branches can the multi stage magnetic drum be used in?

Recycling and waste processing

Ceramic and glass industry

Chemical industry, paints and lacquers

Plastics and rubber industries

Food processing industry