Semi-closed magnetic drums MBO

Magnetic drum in the semi-closed box pattern version serves to unintermitting and automatous separation of ferromagnetic particles coming from dry material (especially coming from wood chips etc.that could be problematic for MBZ magnetic drums in the basic covered version from the point of view of material fraction).

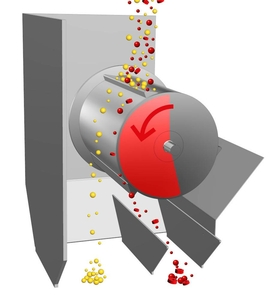

Design of magnetic drum

The semi-closed box of can be also connected to conveyor system easily. The system of permanent magnets makes the separation of magnetic metal particles without the need of interrupting the production cycle easier and simultaneously protects the subsequent machinery (e. g. presses, stampers, mills, shredder) against damage. The heart of the magnetic drum is a set of magnetic cores of crescent-moon shape that the outer part of the drum (made of stainless steel) with stalled tappers revolves round.

SOLLAU 5 year warranty

We can vouch for the quality of our magnetic separators and that is why why we provide a 5 year warranty on them! Our magnetic separators can be relied on! We are a specialist in the field of magnetic separation.

Cleaning of magnetic drum

Metal magnetic adulterants are caught on the surface of the drum and fall off behind the drum axis into the hopper for ferromagnetic contaminants.

Customer care

Your project will be taken care of by us from beginning up to the very end. It does not end with the order placed at us. We will provide the full support for all the time of the use of the separator.

1. We will come

2. We will align and design

3. We will make a made-to-measure product

4. We will install

5. We will put into operation and school in

6. We will provide authorized service

We guarantee tests withing three days!

Make sure that our device perfectly meets your expectations!

We will provide tests of your material on our magnetic separators for FREE!

SOLLAU – our products are welded by real professionals!

SOLLAU certifications:

Authorization to perform welding on pressure equipment according to PED 2014 / 68 / EU

Pressure welder certificate according to EN-ISO 3834 - 2, EN 1090 - 2, EN 13480 - 1 to 5, EN 13445 - 1 to 5

MBO 304

- Drum diameter: 304 mm

- High processing capacity (up to 105 m3/h)

- Up to 4 800 Gauss on the drum surface

| Product | Maximum capacity (m3/h) | Working width (mm) | Datasheet |

|---|---|---|---|

| MBO 304 F 300 | 25 | 300 | display PDF |

| MBO 304 F 400 | 35 | 400 | display PDF |

| MBO 304 F 500 | 45 | 500 | display PDF |

| MBO 304 F 600 | 55 | 600 | display PDF |

| MBO 304 F 700 | 65 | 700 | display PDF |

| MBO 304 F 800 | 75 | 800 | display PDF |

| MBO 304 F 900 | 85 | 900 | display PDF |

| MBO 304 F 1000 | 95 | 1000 | display PDF |

| MBO 304 F 1100 | 105 | 1100 | display PDF |

MBO 406

- Drum diameter: 406 mm

- High processing capacity (up to 200 m3/h)

- Up to 4 400 Gauss on the drum surface

| Product | Maximum capacity (m3/h) | Working width (mm) | Datasheet |

|---|---|---|---|

| MBO 406 F 400 | 45 | 400 | display PDF |

| MBO 406 F 500 | 55 | 500 | display PDF |

| MBO 406 F 600 | 65 | 600 | display PDF |

| MBO 406 F 700 | 75 | 700 | display PDF |

| MBO 406 F 800 | 90 | 800 | display PDF |

| MBO 406 F 900 | 120 | 900 | display PDF |

| MBO 406 F 1000 | 140 | 1000 | display PDF |

| MBO 406 F 1100 | 160 | 1100 | display PDF |

| MBO 406 F 1200 | 180 | 1200 | display PDF |

| MBO 406 F 1300 | 200 | 1300 | display PDF |

MBO 506

- Drum diameter: 506 mm

- High processing capacity (up to 285 m3/h)

- Up to 4 300 Gauss on the drum surface

| Product | Maximum capacity (m3/h) | Working width (mm) | Datasheet |

|---|---|---|---|

| MBO 506 F 500 | 70 | 500 | display PDF |

| MBO 506 F 600 | 85 | 600 | display PDF |

| MBO 506 F 700 | 105 | 700 | display PDF |

| MBO 506 F 800 | 125 | 800 | display PDF |

| MBO 506 F 900 | 145 | 900 | display PDF |

| MBO 506 F 1000 | 180 | 1000 | display PDF |

| MBO 506 F 1100 | 215 | 1100 | display PDF |

| MBO 506 F 1200 | 250 | 1200 | display PDF |

| MBO 506 F 1300 | 285 | 1300 | display PDF |

Which industrial branches can the magnetic drum in the semi-enclosed design be used in?

The semi-closed magnetic drums find use in recycling and mining as well as in wood, plastic, ceramic, glass and food industry.

Recycling and waste processing

Machining and foundry industry

Paper industry

Tobacco industry

Ceramic and glass industry

Mining and quarrying industry

Cement and lime industry

Chemical industry, paints and lacquers

Automotive industry

Plastics and rubber industries

Thermal power plants

Wood industry