Sorting line for additional sorting of plastic type waste

Compound of the line

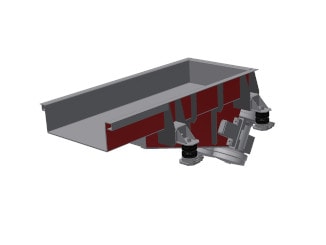

Vibrating feeder

Case study

Principal types of challenges

- there are also ferrous and non-ferrous adulterants (cans, lids, plugs etc.) in the quantity of some per cents besides all types of plastic (PET, HDPE, PP, plastic sheet, tetrapack etc.) ocurring in the plastic municipal waste of relatively big fraction (of 50 x 10 x 1 mm to 300 x 250 x 1 mm)

- big quantity being processed (up to 1,800 kg/hour) and a high layer of the material

- being transported

- need of separating of both magnetic and non-magnetic metal adulterants

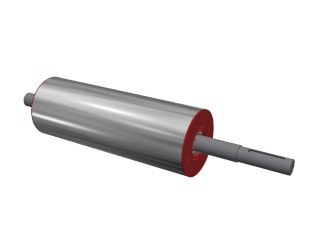

Solution provided by SOLLAU s.r.o. company: a set of separators for separation of both magnetic and non-magnetic metal adulterantshas been delivered. The ferrite magnet above DND-AC Ms4 EKO conveyor-belt with automatic cleaning has a deep magnetic field and that is why it manages to pull out ferromagnetic objects out of the depth of up to 320 mm and at the same time it portects against the damage by iron particles also ECS-C 2000 RAM separator for non-ferrous metals. MV 245 N 1200 neodym magnetic roller separates the iron contaminants from the lower layers of the material and it protects ECS-C 2000 RAM magnetic separator against the damage. ECS-C 2000 RAM separator for non-ferrous metals having a magnetic rotor laid centrically catches all bigger and well-conductive non-magnetic objects in a reliable way.

Customer care

Your project will be taken care of by us from beginning up to the very end. It does not end with the order placed at us. We will provide the full support for all the time of the use of the separator.

1. We will come

2. We will align and design

3. We will make a made-to-measure product

4. We will install

5. We will put into operation and school in

6. We will provide authorized service

We guarantee tests withing three days!

Make sure that our device perfectly meets your expectations!

We will provide tests of your material on our magnetic separators for FREE!

SOLLAU – our products are welded by real professionals!

SOLLAU – our products are welded by real professionals!