Tank magnetic separators MSP-C

Trap magnets for tank trucks are designed to separate ferromagnetic particles from bulk and liquid materials transported by tank trucks. Many raw materials (in the food industry, agriculture, building industry etc.) are carried by tank trucks and a great emphasis is put on the purity of these materials. Therefore, we recommend that you apply our tank magnetic separator to clean your products. Our tank magnetic separator can be easily connected to a pipe or hose (used for unloading or loading of the transported material by air pressure), as we may fit it with fire hose couplings or other connectors compatible with the tank outlet/inlet. During unloading the final phase of magnetic separation is performed (as the last step of the transport chain). The haulier can thus guarantee to the customer that the raw material is free of ferrous contaminants.

Benefits of using the magnetic trap

- Material without ferromagnetic particles

- Guarantee to the customer that the transported raw material is free of ferrous substances

- Easy installation and operation = drivers' willingness to use the separator

SOLLAU 5 year warranty

We can vouch for the quality of our magnetic separators and that is why why we provide a 5 year warranty on them! Our magnetic separators can be relied on! We are a specialist in the field of magnetic separation.

We produce the tank magnetic separator in connection diameters from 80 to 150 mm as standard. However, we can adjust the connection dimensions and the connection mode (fire hose couplings, flange, screw connections, special connectors etc.) according to your wishes as well.

We are the manufacturer of these magnetic filters. We guarantee a top technical design and a favorable price.

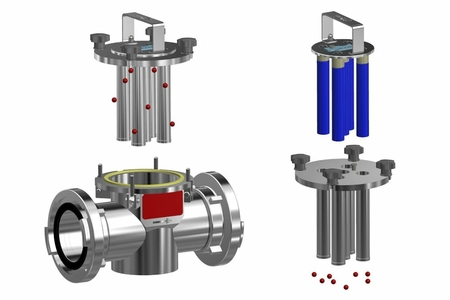

The magnetic filter for tank trucks includes several parts:

- Magnetic component

- Magnetic core

- Stainless steel tubes

- Separator body

The magnetic core consists of magnetic rods, placed in stainless steel protective tubes. Thanks to this "tube in tube" system, the magnetic rods are protected and their lifetime is significantly extended. This also eliminates the risk of flaking off a piece of magnet or its nickel plating and subsequent contamination of the cleaned material.

The magnetic component is equipped with magnetic rods, formed with the strongest neodymium magnets. These magnetic rods create an ingenious labyrinth so that the medium to be cleaned is in contact with several magnetic rods when being pumped from the tank. Thanks to this cleaning labyrinth and the applied strong neodymium magnets, the maximum efficiency of the magnetic separator is ensured - we can capture ferromagnetic impurities starting with 1 µm!

The magnetic component is fixed to the separator body with 4 hinge screws with wing nuts, which make the withdrawal of the component from the separator body very easy.

How will the magnetic filter be cleaned?

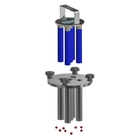

Cleaning the separator is very easy and fast. It is performed in several steps:

- Pulling the magnetic component out of the separator body

- Removing the magnetic cores from the stainless steel protective tubes (metal particles fall off)

- Reverse assembly

How is the trap magnet for tank trucks used in practice?

The separator is usually stored in a transport box of the tank truck. The operator (driver) connects the separator to the pipeline (hose) through which the material flows from the tank at the place of unloading. In the standard version, the separator is provided with a thread on which the needed connecting piece (usually a fire hose coupling) can be screwed in (so that the connection to the tank is quick and comfortable). We manufacture these magnetic separators and can therefore adapt them to your requirements.

We also often encounter a situation where the separator is firmly installed at the material entry (e.g. when receiving material into a silo).

SOLLAU – our products are welded by real professionals!

SOLLAU certifications:

Authorization to perform welding on pressure equipment according to PED 2014 / 68 / EU

Pressure welder certificate according to EN-ISO 3834 - 2, EN 1090 - 2, EN 13480 - 1 to 5, EN 13445 - 1 to 5

Exchange of magnetic rods

Exchange of magnetic rods

The design of the magnetic filter allows for easy replacing of the magnetic rods (damaged e.g. by improper handling). This exchange is really easy - just loosen one screw and replace the rod. Therefore, no manufacturer's service intervention is required.

- Possibility of using various pipe connectors (e. g., fire hose couplings - G3", G4" and others, fittings, flanges etc.)

- Low weight = easy handling

- 11 500 Gauss in contact with the treated material

- As standard, we produce these separators with connecting diameters of DN 80, DN 100, and DN 150

- Possibility of tailor-made production

- Heavy duty stainless steel design

- Option – the separator can be equipped with a sieve to capture non-magnetic particles

| Product | Input/output diameter (mm) | Datasheet |

|---|---|---|

| MSP-C 80 N | 80 | display PDF |

| MSP-C 100 N | 100 | display PDF |

| MSP-C 150 N | 150 | display PDF |