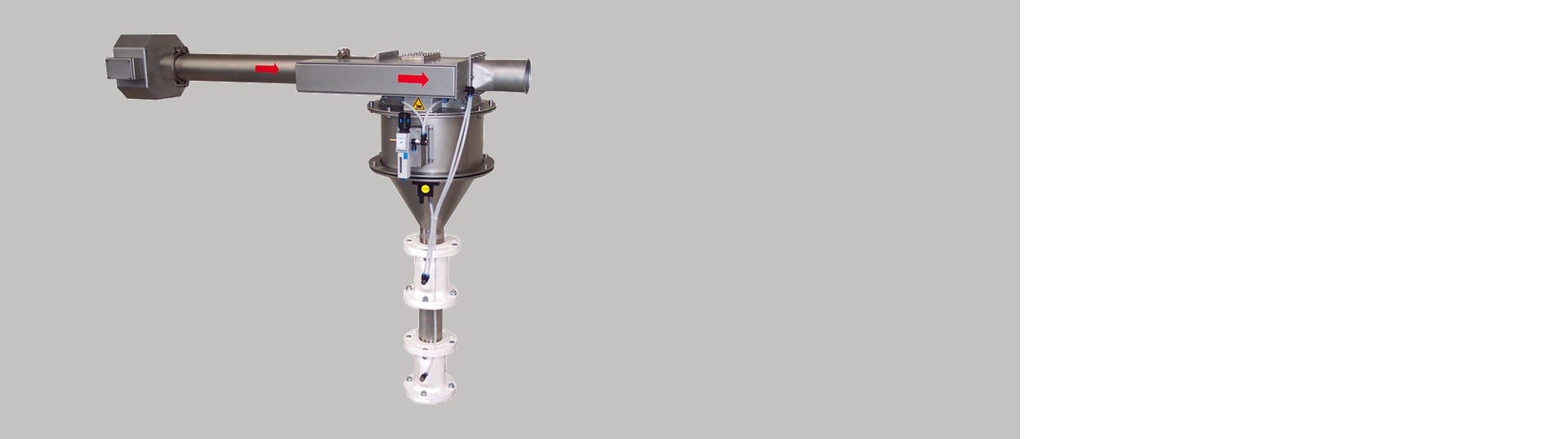

Pipe metal detector P-TRON 05 GM V2

P-TRON 05 GM V2 pipe metal detector is used to detect and eject metal particles from granulates or powders transported in horizontal or vertical suction or pressure lines. It is made of stainless steel with a maximum emphasis on hygienic design.

The detector is fully automatic, equipped with a high-speed reject flap that instantly diverts the detected contaminant from the product stream and minimizes the loss of a good product.

The main advantages of this metal detector include the low price (resulting in a very fast return on investment) and easy installation.

Thanks to the sophisticated detection technology, this detector is immune to external interference and that is why it can detect metals of 0.4 mm! As standard, we supply it with an inlet opening with a diameter of 38 - 200 mm. The standard version is designed for materials with a size of 0.5 - 8.0 mm. As an option, we also offer variants for powder materials from 0.0 mm.

The detector is fully automatic, equipped with a high-speed reject flap that instantly diverts the detected contaminant from the product stream and minimizes the loss of a good product. Thanks to the extremely fast reaction time (under 50 ms) it can reliably detect and eject contaminants even at a speed of 30 m/s.

Installation is very easy - no metal free zone is required.

This detector is equipped with a powerful AMD 05 control unit with a range of advanced functions such as automatic product setup, an automatic calibration or digital filtration system. The unit is fitted with a 5-line LCD display and controlled by 4 ergonomic buttons. Its operation is simple and intuitive.

Principle advantages of a pipeline metal detector

- Metal detector for compressed-air transport.

- All metals both free and hidden in the material are detected and separated automatically.

- Very exact and relible detection of metals.

- Option to deliver a special design for abrasive materials or into an explosive ambient with the atex certificate.

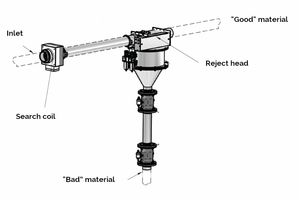

Principle of detector function

The metal detector of the P-TRON series is installed into a pipeline used for the vacuum transport of bulk materials. The inspected material passes through the reject assembly. If the material is contaminated with metal particles, the contaminant in the product stream alters the high frequency field generated by the search coil. The electronics evaluate this signal and generate an impulse for the solenoid valve and double actuating air cylinder of the reject assembly. The contaminant is instantly diverted from the good product stream assuring minimal good product loss. The reject flap then automatically returns to its normal position. The detector operation including the elimination of contaminants is fully automatic.

Thanks to the high-speed reject flap used, its operation is very fast and accurate, enabling minimization of good material loss.The reject time is adjustable.

The P-TRON 05 GM V2 pipeline metal detector is:

- Reliable – in process and detection

- Durable – in technology and performance

- Comfortable – in design and data management

Optional equipment

The P-TRON 05 GM V2 detectors can be supplied with a wide range of additional equipment:

- Signal units – beacon, buzzer

- Reject counter

- MesuSET – operation of detector via laptop

- MesuNET – network integration and remote maintenance

Special design

Do you have special requirements regarding the metal detector design? The most common requirements include:

- Integrated control unit

- Units can be painted in customer specific colour code

- Version for explosive atmospheres

- Larger container for removed contaminants

- Reject flap made from polished stainless steel

- Reject flap for powder materials

Contact us – we will elaborate a solution just for you.

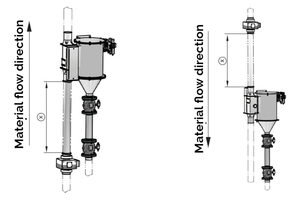

Dimensions

P-TRON 05 GM V2 H – horizontální instalace

| Ø A | B (mm) | C (mm) | D (mm) | E (mm) | G (mm) | Ø H (mm) | K (mm) | L (mm) | M (mm) | Ø N (mmp | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Velikost 1 | 38, 45, 50, 55, 60 | 398 | 480 | 1286 | 350 | 175 | 60 | 187 | 90 | 160 | 11,5 |

| Velikost 2 | 60, 70, 75, 80 | 340 | 430 | 1410 | 350 | 175 | 89 | 187 | 98 | 160 | 11,5 |

| Velikost 3 | 85 / 100 / 120 | 660 / 296 / 310 | 669 | 1447 | 453 | 235 | 89 | 200 | 96 | 170 | 13 |

| Velikost 4 | 150 / 200 | 380 / 450 | 1055 / 915 | 3040 | 690 | 345 | 200 | 250 | 340 | 350 | 13 |

P-TRON 05 GM V2 V UP – vertical installation

| Ø A | B (mm) | C (mm) | D (mm) | E (mm) | G (mm) | Ø H (mm) | K (mm) | L (mm) | M (mm) | Ø N (mmp | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Size 1 | 38, 45, 50, 55, 60 | 398 | 340 | 1500 | 350 | 175 | 60 | 473 | 246 | 160 | 11,5 |

| Size 2 | 60, 70, 75, 80 | 480 | 430 | 1620 | 350 | 175 | 89 | 473 | 250 | 160 | 11,5 |

| Size 3 | 85 / 100 / 120 | 430 / 296 / 310 | 669 | 1630 | 453 | 235 | 89 | 538 | 324 | 170 | 13 |

| Size 4 | 150 / 200 | 380 / 450 | 1055 / 915 | 2873 | 690 | 345 | 200 | 250 | 520 | 350 | 13 |

P-TRON 05 GM V2 V DOWN – vertical installation

| Ø A | B (mm) | C (mm) | D (mm) | E (mm) | G (mm) | Ø H (mm) | K (mm) | L (mm) | M (mm) | Ø N (mmp | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Size 1 | 38, 45, 50, 55, 60 | 398 | 340 | 1500 | 350 | 175 | 60 | 473 | 246 | 160 | 11,5 |

| Size 2 | 60, 70, 75, 80 | 480 | 430 | 1620 | 350 | 175 | 89 | 473 | 250 | 160 | 11,5 |

| Size 3 | 85 / 100 / 120 | 430 / 296 / 310 | 669 | 1630 | 453 | 235 | 89 | 538 | 324 | 170 | 13 |

| Size 4 | 150 / 200 | 380 / 450 | 1055 / 915 | 2873 | 690 | 345 | 200 | 250 | 520 | 350 | 13 |

We can supply units with different height, inside diameters, frames, etc. to meet your requirements.

Contact us – we will prepare a solution just for you.

Sensitivity of a metal detector

The detector sensitivity depends on many parameters, such as the aperture diameter (the smaller the aperture, the higher the sensitivity), the material speed, the density of the product, its temperature, humidity, etc.

Maximum obtainable sensitivity can be established by testing your product sample in our laboratory. We will perform these tests free of charge. Please contact us, we will discuss the test execution as well as the dispatch of your material samples.17.03.2022

Sensitivity diagram the detector P-TRON 05 GM V2

| Model | P-TRON 05 GM V2 38 | P-TRON 05 GM V2 45 | P-TRON 05 GM V2 50 | P-TRON 05 GM V2 55 | P-TRON 05 GM V2 60 | P-TRON 05 GM V2 65 | P-TRON 05 GM V2 70 | P-TRON 05 GM V2 75 | P-TRON 05 GM V2 80 | P-TRON 05 GM V2 100 | P-TRON 05 GM V2 120 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Aperture diameter (mm) | 38 | 45 | 50 | 55 | 60 | 65 | 70 | 75 | 80 | 100 | 120 |

| Fe ball (mm) | 0,4 | 0,5 | 0,6 | ||||||||

| NonFe ball (mm) | 0,5 | 0,7 | 0,7 | ||||||||

| SS ball (mm) | 0,8 | 0,9 | 1,0 | ||||||||

AMD 05 Control unit

A first-rate control unit is essential for the proper functioning of any detector. Our control unit is made with an emphasis on the high quality of workmanship and of the employed components.

The result is a stable control unit with a wide range of functions (just to name a few):

The result is a stable control unit with a wide range of functions (just to name a few):

- Auto-balance including the suppression of interfering signals and automatic sensitivity calibration

- Multi-filter system using digital filtration for maximum stability in harsh environments

- Self-monitoring system ensures that all important components function properly

- Touch screen control panel – modern design

- Easy 4-button intuitive operation

- 5-line LCD display

- Product storage memory backup – for up to 500 products

- Metal detector network and remote service - diagnostics, parameter change, SW update

Scope of delivery

The delivery of P-TRON 05 GM V1 detectors includes:

- Detection head

- Control unit (= electronics mounted in a metal cabinet)

- Separation unit

- Connecting cables

- Installation hardware

- Power supply: 100 – 240 V AC, 50/60 Hz

- Power consumption: max. 50 W

- Type of electrical protection: IP 54

- Min. working temperature: - 10 °C

- Max. working temperature: + 50 °C

- Relative air humidity: 0 – 95 % (without condensation)

- Transport speed: 0.5 – 30 m/sec

- Required air pressure: 6 – 10 bar

- Compressed air consumption during the separation: 0.2 l

- Material: diameter: 0,5 – 8,0 mm

- Material (powder option): 0.0 – 2.0 mm

- Power cable: 1.8 m with a plug