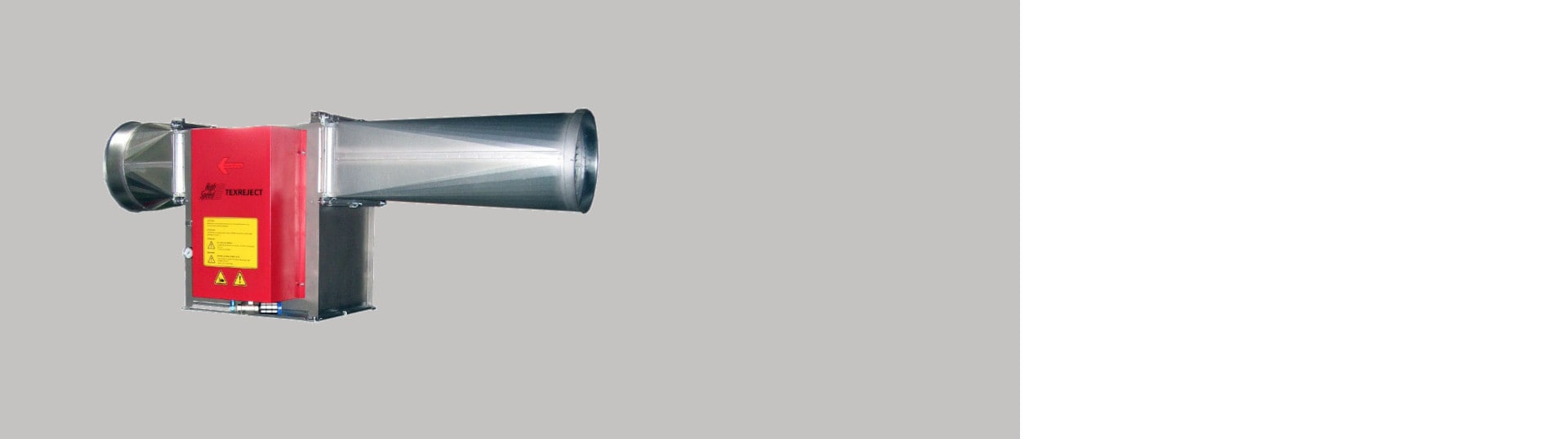

High-Speed TEXREJECT eject gate

Fast acting eject gate TEXREJECT is used to remove metal contaminants from pneumatically conveyed textile fibres (by pressure and also by vacuum). Mostly is the eject gate used together with the metal detector METRON 05 PowerLine that detects the metal particles even at a transport speed of 30 m/s. Subsequently, these metals are reliably ejected by the high-speed TEXREJECT unit and the cleaned product is free of metal contaminants. The fast acting eject gate is designed so that the rejection takes place very quickly - in 0.05 seconds. This enables to reject metals even at high transport speeds and reduces good material loss to a minimum.

As the structure of the eject unit is very robust and durable, no wear even after 300,000 eject cycles is visible.

As standard, the eject gate is installed into pipes with a diameter of 220, 250, 300, 350 and 400 mm. On request, the unit can be supplied also for other pipe diameters and shapes.

In combination with a collection container, the eject gate is also suitable for vacuum transport.

Installation of the reject unit is easy and fast.