Pipeline metal detector P-TRON 03 FM

The cost-effective P-TRON 03 FM pipe metal detector is used to detect and reject metal particles from vacuum-fed bulk materials. It is designed for installation into vertical and horizontal pipes. It is often used to detect metals in plastic material (granules, re-granulate, plastic flakes).

The detector is fully automatic, equipped with a high-speed reject flap that instantly diverts the detected contaminant from the product stream and minimizes the loss of a good product.

The main advantages of this metal detector include the low price (resulting in a very fast return on investment) and easy installation.

We supply this detector with an inlet opening of 38 – 80 mm as standard.

The control unit is very simple to operate, stable and durable.

Principle advantages of a pipeline metal detector

- Detection of metals for compressed-air pipelines without the interruption of the flow of material

- All metals both free and hidden in the material are detected and separated automatically

- Flexible building-in into the existing pipeline distribution systems – regardless of the direction of material flow, quickly and cheaply

- Convincingly easy control

- Exact and reliable operation

Working principle

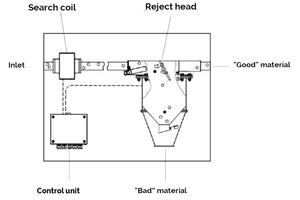

The metal detector of the P-TRON series is installed into a pipeline used for the vacuum transport of bulk materials. The inspected material passes through the reject assembly. If the material is contaminated with metal particles, the contaminant in the product stream alters the high frequency field generated by the search coil. The electronics evaluate this signal and generate an impulse for the solenoid valve and double actuating air cylinder of the reject assembly. The contaminant is instantly diverted from the good product stream assuring minimal good product loss. The reject flap then automatically returns to its normal position. The detector operation including the elimination of contaminants is fully automatic.

The metal detector of the P-TRON series is installed into a pipeline used for the vacuum transport of bulk materials. The inspected material passes through the reject assembly. If the material is contaminated with metal particles, the contaminant in the product stream alters the high frequency field generated by the search coil. The electronics evaluate this signal and generate an impulse for the solenoid valve and double actuating air cylinder of the reject assembly. The contaminant is instantly diverted from the good product stream assuring minimal good product loss. The reject flap then automatically returns to its normal position. The detector operation including the elimination of contaminants is fully automatic.

Thanks to the high-speed reject flap used, its operation is very fast and accurate, enabling minimization of good material loss.The reject time is adjustable.

The P-TRON 03 FM pipeline metal detector is:

- Reliable – in process and detection

- Durable – in technology and performance

- Fast – in response and cleaning

Optional equipment

The P-TRON 03 FM detectors can be supplied with a wide range of additional equipment:

- Signal units – beacon, buzzer

- Reject counter

Dimensions

P-TRON 03 FM H – horizontal installation

| ØA | B (mm) | C (mm) | D (mm) | E (mm) | G (mm) | K (mm) |

|---|---|---|---|---|---|---|

| 38, 45, 50, 55, 60 | 270 | 340 | 554 | 75 | 90 | 150 |

| 65, 70, 75, 80 | 310 | 430 | 566 | 80 | 98 | 160 |

P-TRON 03 FM V – vertical installation

| ØA | B (mm) | C (mm) | D (mm) | E (mm) | G (mm) |

|---|---|---|---|---|---|

| 38, 45, 50, 55, 60 | 270 | 340 | 246 | 150 | 600 |

| 65, 70, 75, 80 | 310 | 430 | 250 | 160 | 620 |

We can supply units with different height, inside diameters, frames, etc. to meet your requirements.

Contact us – We will ask you to specify the required modifications so that the offer can be elaborated exactly according to your requirement.

Sensitivity of a metal detector

The detector's sensitivity depends on many parameters, such as the aperture dimensions (the lower is the aperture height, the higher is the detector sensitivity), the conveyor belt speed, the density of the product, its temperature and humidity, etc.

Maximum obtainable sensitivity can be established by testing your product sample in our laboratory. We will perform these tests free of charge. Please contact us, we will discuss the test execution as well as the dispatch of your material samples.

Sensitivity diagram the detector P-TRON 03 FM:

| Model | P-TRON 03 FM 38 | P-TRON 03 FM 45 | P-TRON 03 FM 50 | P-TRON 03 FM 55 | P-TRON 03 FM 60 | P-TRON 03 FM 65 | P-TRON 03 FM 70 | P-TRON 03 FM 75 | P-TRON 03 FM 80 |

|---|---|---|---|---|---|---|---|---|---|

| Aperture diameter (mm) | 38 | 45 | 50 | 55 | 60 | 65 | 70 | 75 | 80 |

| Fe ball (mm) | 0,6 | 0,9 | |||||||

| NonFe ball (mm) | 0,6 | 1,0 | |||||||

| SS ball (mm) | 1,0 | 1,5 | |||||||

AMD 03 Control unit

A first-rate control unit is essential for the proper functioning of any detector. Our control unit is made with an emphasis on the high quality of workmanship and of the employed components.

The result is a stable control unit with a wide range of functions (just to name a few):

The result is a stable control unit with a wide range of functions (just to name a few):

- Easy control

- Self-monitoring system ensures that all important components function properly

- Reduction of conveyor vibration

- Simple maintenance and diagnostics

- Continuous balance unit

- Optical detection and failure signaling

Scope of delivery

The delivery of P-TRON 03 FM detectors includes:

- Detection head

- Control unit (= electronics mounted in a metal cabinet)

- Connecting cables

- Installation hardware

Datasheet

- Power supply: 100 – 240 V AC, 50/60 Hz

- Power consumption: 0,4 A

- Type of electrical protection: IP 54

- Min. working temperature: - 10 °C

- Max. working temperature: + 50 °C

- Relative air humidity: 0 – 95 % (without condensation)

- Transport speed: 0.5 – 30 m/sec

- Compressed air consumption during the separation: 0.2 l

- Material: diameter: 0,5 – 8,0 mm

- Power cable: 1.8 m with a plug