Metal detector METRON 05 PowerLine for pneumatic conveying systems

The METRON 05 PowerLine metal detector for pneumatic transport is used to detect metal particles in bulk materials transported in pneumatic conveying systems (pressure or vacuum). It is the only metal detector in the world that can be directly integrated into a pneumatic transport system without the use of a sensing tube. Thanks to this patented design the detector is immune to external electromagnetic interference and can achieve extremely accurate metal detection.

This high-precision metal detector enables to detect metals even at a conveying speed of up to 30 m/s! It is often installed in combination with fast acting eject gate TEXREJECT , what results in the ejection of metal contaminants with minimal good material loss.

The basic size range is available for pipe diameters of 250, 300, 350, and 400 mm, adaptors for other diameters are also available.

Easy installation - as no sensing tube is needed, the detector can be installed directly into the existing pipeline by means of quick clamps or flanges. It cannot be easier!

This detector is equipped with a powerful AMD 05 control unit with a range of advanced functions such as automatic product setup, automatic calibration, or a digital filtration system. The unit is equipped with a 5-line LCD display and controlled by 4 ergonomic buttons. Its operation is simple and intuitive.

Principle advantages of a metal detector for pressure pipeline transport

- Metal detector with an opening for installment into pressure pipeline transport apparatus

- All metal particles are detected and it is both off-shell particles and the ones in the form of inclusions in the end product.

- Highly exact and relible detection of metals.

- Resistant against electromagnetic disturbance thanks to patented design.

- Very simple intallment thanks to absence of additional removable tube.

- Minimum level of material losses.

The METRON 05 PowerLine metal detector for pneumatic conveying systems is:

- Reliable – in process and detection

- Durable – in technology and performance

- Easy - installation and operation

Optional equipment

The METRON 05 PowerLine detectors can be supplied with a wide range of additional equipment:

- Fast acting eject gate Texreject

- Signal units – beacon, buzzer

- Container for removed contaminants (for pressure as well as vacuum conveying systems)

- Magnetic testing rod

Special design

Do you have special requirements regarding the metal detector design? The most common requirements include:

- Integrated control unit

- Units can be painted in customer specific colour code

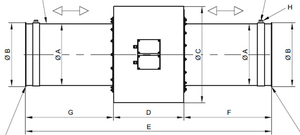

Dimensions

| A: (mm) | B: (mm) | C: (mm) | D: (mm) | E: (mm) | F: (mm) | G: (mm) | H: (mm) | Weight (kg) |

|---|---|---|---|---|---|---|---|---|

| 220 | 234 | 450 | 350 | 1400 | 525 | 525 | M8 | 40 |

| 250 | 264 | 450 | 350 | 1400 | 525 | 525 | M8 | 40 |

| 300 | 314 | 500 | 400 | 1400 | 500 | 500 | M8 | 45 |

| 350 | 364 | 550 | 400 | 1400 | 500 | 500 | M8 | 55 |

| 400 | 414 | 600 | 450 | 1400 | 475 | 475 | M8 | 75 |

| 630 | 664 | 850 | 700 | 2200 | 650 | 850 | M10 | 150 |

Sensitivity of a metal detector

The detector sensitivity depends on many parameters, such as the aperture diameter (the smaller the aperture, the higher the sensitivity), the material speed, the density of the product, its temperature, humidity, etc.

Maximum obtainable sensitivity can be established by testing your product sample in our laboratory. We will perform these tests free of charge. Please contact us, we will discuss the test execution as well as the dispatch of your material samples.17.03.2022

Sensitivity diagram the detector METRON 05 PowerLine

| Model | 220 | 250 | 300 | 350 | 400 | 630 |

|---|---|---|---|---|---|---|

| Sensitivity – Fe ball (mm) | 2,5 | 2,5 | 3,0 | 3,2 | 4,0 | 6,0 |

AMD 05 Control unit

A first-rate control unit is essential for the proper functioning of any detector. Our control unit is made with an emphasis on the high quality of workmanship and of the employed components.

The result is a stable control unit with a wide range of functions (just to name a few):

The result is a stable control unit with a wide range of functions (just to name a few):

- Auto-balance including the suppression of interfering signals and automatic sensitivity calibration

- Multi-filter system using digital filtration for maximum stability in harsh environments

- Self-monitoring system ensures that all important components function properly

- Touch screen control panel – modern design

- Easy 4-button intuitive operation

- 5-line LCD display

- Product storage memory backup – for up to 500 products

- Metal detector network and remote service - diagnostics, parameter change, SW update

Scope of delivery

The delivery of METRON 05 D detectors includes:

- Detection head

- Control unit (= electronics mounted in a metal cabinet)

- Connecting cables

- Installation hardware

- User manual

Datasheet

- Power supply: 100 – 240 V AC, 50/60 Hz

- Power consumption: max. 50 W

- Type of protection: IP 54

- Min. working temperature: - 10 °C

- Max. working temperature: + 50 °C

- Relative air humidity: 0 – 95 % (without condensation)

- Conveying speed: 0.5 – 30 m/sec

- Power cable: 1.8 m with plug