Magnetic sheet separator / sheet fanner MC

The MC Sollau magnetic sheet fanner is standardly fitted with strong ferrite magnets and serves to an easy unstacking of stacked metal sheets. Upon a special request the sheet separators with extremely powerful neodymium magnets (i. e., rare earth magnets) are available.

Basic components of the magnetic sheet separator are a magnetic block in stainless steel sheathing and a carrying bracket (for clamping the magnetic block, it can be a part of the delivery).

Which way do magnetic clarifiers of metal plates work?

Standard ferrite sheet separators are intended for ferromagnetic metal sheets with thickness to 3 mm and for stacks of metal sheets having the maximum height to 530 mm. To choose the correct type (and amount) of required magnetic sheet separators, it is necessary to define the size and thickness of single ferromagnetic metal sheets, the stack height and also the surface treatment of metal sheets (I. e., whether the metal sheets are sticky, e. g. with the oil treated surface, or dry) - because all these parameters influence the use of sheet separators.

Therefore, the client working e. g. with dry metal sheets with thickness of 1 mm, dimensions of which are 900 x 600 mm and having the stack height of 50 mm will need a diametrically different magnetic sheet separator than that processing oiled metal sheets - with thickness of 2,5 mm, measuring 2000 x 1000 mm and with the stacked height of 500 mm (in the former case, the separation can be performed with one piece of the weakest model of the MC-F80 sheet separator. In the latter case, several sheet separators of the strongest MC-F530 type are to be applied simultaneously).

Advantages of the permanent magnetic sheet fanners

- the magnetic field, generated by these sheet separators is strong, steady and permanent for many years,

- small size and low weight,

- in comparison to other systems for separation of steel sheets (e. g. by means of the compressed air etc.), separating the sheets by means of the sheet separators is by far cheaper,

- no difficult mechanical separating the metal sheets being glued together with an oil film, polishing agent etc.; a risk of surface damage to metal sheets will be reduced at their automatic take-off and processing as well,

- the unique structural design allows to use only one basic bracket for clamping up to four various types of magnetic blocks of the sheet separators; (i.o.w., if the client already bought one mounting bracket, he would not need another new bracket anymore; if there is a need of a sheet separator with a different power, then he will buy only a magnetic block, which can be easily fixed to the bracket by means of screws),

- magnetic blocks can be also used separately, i. e. without the mounting bracket (nevertheless, the application of the sheet separator with the bracket is far simpler).

Which way are magnetic sheet separators used?

Application of the magnetic sheet separator is very simple; the metal sheet separator will be simply placed to the metal sheet stack only. By inducing magnetic fields into a stack of steel sheets or plates, repelling forces are created from sheet to sheet, forcing them to separate from each other (these can be taken off to a subsequent treatment - quickly, comfortably and mainly in a safe way - without using tools; the sheet under the upper steel sheet will be shifted up after the take-off of the upper sheet automatically).

Easy ordering at the e-shop

Which industrial branches can the magnetic sheet separator be use of in?

The extra strong sorting magnet is multipurpose, also thanks to its watertightness.

MC-F

- Attractive price/performance ratio

- Standard ferrite design

- For stacks up to 530 mm

- Max. sheet thickness: 3 mm

| Product | Max. height of the stack of sheets (mm) | Max. metal sheet thickness (mm) | Datasheet (EN) |

|---|---|---|---|

| MC-F80 | 80 | 3 | display PDF |

| MC-F130 | 130 | 3 | display PDF |

| MC-F230 | 230 | 3 | display PDF |

| MC-F330 | 330 | 3 | display PDF |

| MC-F430 | 430 | 3 | display PDF |

| MC-F530 | 530 | 3 | display PDF |

Some products from this model family are available for immediate purchase. We are constantly extending the offer of our magnetic separators in stock so that we can deliver them to you immediately. Please, contact our dealer to inform for their current availability.

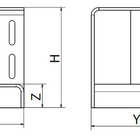

| Name of the console | Code of console | H (mm) | X (mm) | Y (mm) | Z (mm) | Connecting screws | |

|---|---|---|---|---|---|---|---|

| Console 01 | K01 | 170 | 110 | 160 | 40 | M8 | |

| Console 02 | K02 | 280 | 110 | 200 | 50 | M8 | |

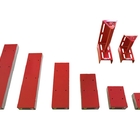

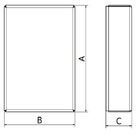

| Model | Max. height of the stack of sheets (mm) | A (mm) | B (mm) | C (mm) | Console connection | Max. sheet strength (mm) | Recommended console type | Weight (kg) |

|---|---|---|---|---|---|---|---|---|

| MC-F80 | 80 | 110 | 115 | 42 | 2 x thread M8 | 3 | K01 | 2,9 |

| MC-F130 | 130 | 160 | 115 | 42 | 4 x thread M8 | 3 | K01 | 4,2 |

| MC-F230 | 230 | 260 | 115 | 42 | 4 x thread M8 | 3 | K01 | 6,8 |

| MC-F330 | 330 | 360 | 115 | 42 | 4 x thread M8 | 3 | K01/K02 | 9,4 |

| MC-F430 | 430 | 460 | 115 | 42 | 4 x thread M8 | 3 | K02 | 12,1 |

| MC-F530 | 530 | 560 | 115 | 42 | 4 x thread M8 | 3 | K02 | 14,5 |